An optical module that can adopt liquid immersion refrigeration and its manufacturing method

A technology of liquid immersion and manufacturing method, applied in the field of optical communication, can solve the problems of difficult optical modules, unpredictable optical reflection, refraction, affecting the optical path, etc., and achieves the effects of simple assembly, low production and testing costs, and high integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

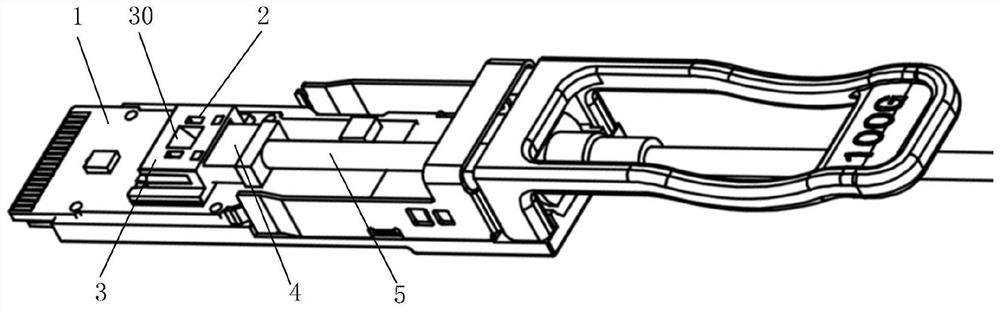

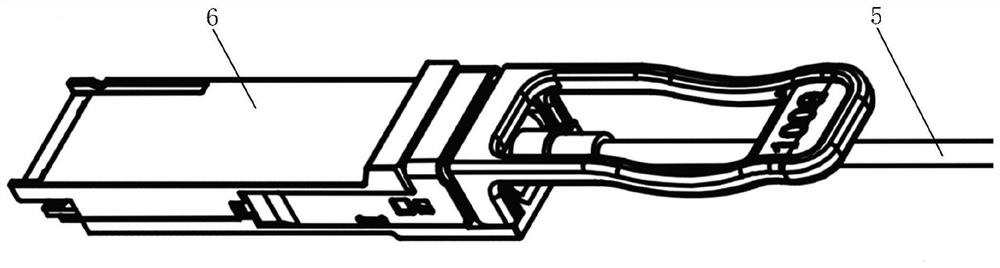

[0036] An embodiment of the present invention provides an optical module that can adopt liquid immersion cooling, such as figure 1 and figure 2 As shown, the optical module is a QSFP+ packaged optical module, which mainly includes a PCB board 1 , an optoelectronic device 2 , an optical lens 3 and an optical connector 4 . The optoelectronic device 2 is directly mounted on the PCB 1, and the optical lens 3 is fixed above the optoelectronic device 2. Here, the optical lens 3 can be fixed on the optoelectronic device 2 by glue curing. Above, optical path transmission is realized; one end (ie, the left end in the figure) of the optical connector 4 is connected to the optical lens 3, and the other end (ie, the right end in the figure) is extended by an optical cable 5 with a pigtail. Wherein, the length of the optical cable 5 can be specifically determined according to the use requirements of the liquid cooling immersion depth.

[0037] The outside of the optical module is molded...

Embodiment 2

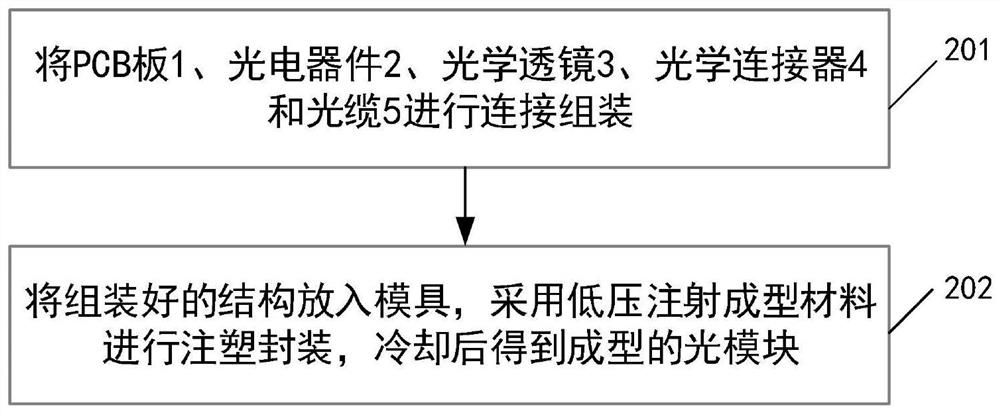

[0052] On the basis of the above-mentioned embodiment 1, the embodiment of the present invention also provides a method for manufacturing an optical module, which is used for manufacturing the optical module described in embodiment 1 that can adopt liquid immersion cooling. Such as image 3 As shown, the optical module manufacturing method provided by the embodiment of the present invention mainly includes the following steps:

[0053] Step 201 , connect and assemble the PCB board 1 , the optoelectronic device 2 , the optical lens 3 , the optical connector 4 and the optical cable 5 .

[0054] The specific assembly method can be combined with figure 1 , follow these steps:

[0055] First, the optoelectronic device 2 is mounted on the PCB 1 , and the optical lens 3 is fixed above the optoelectronic device 2 . Wherein, the optoelectronic device 2 can specifically be mounted and fixed on the PCB board 1 where the heat conduction hole is provided, that is, the bottom of the opto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tackiness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com