Fan bridge cable

A cable and bridge technology, which is applied in the field of power cable manufacturing, can solve the problems of low tensile strength of insulating materials, flame retardancy, high mechanical properties of cold resistance and oil resistance, poor flame retardancy of ethylene-propylene insulation, etc., to achieve excellent Mechanical properties and electrical properties, excellent aging resistance, easy friction and heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

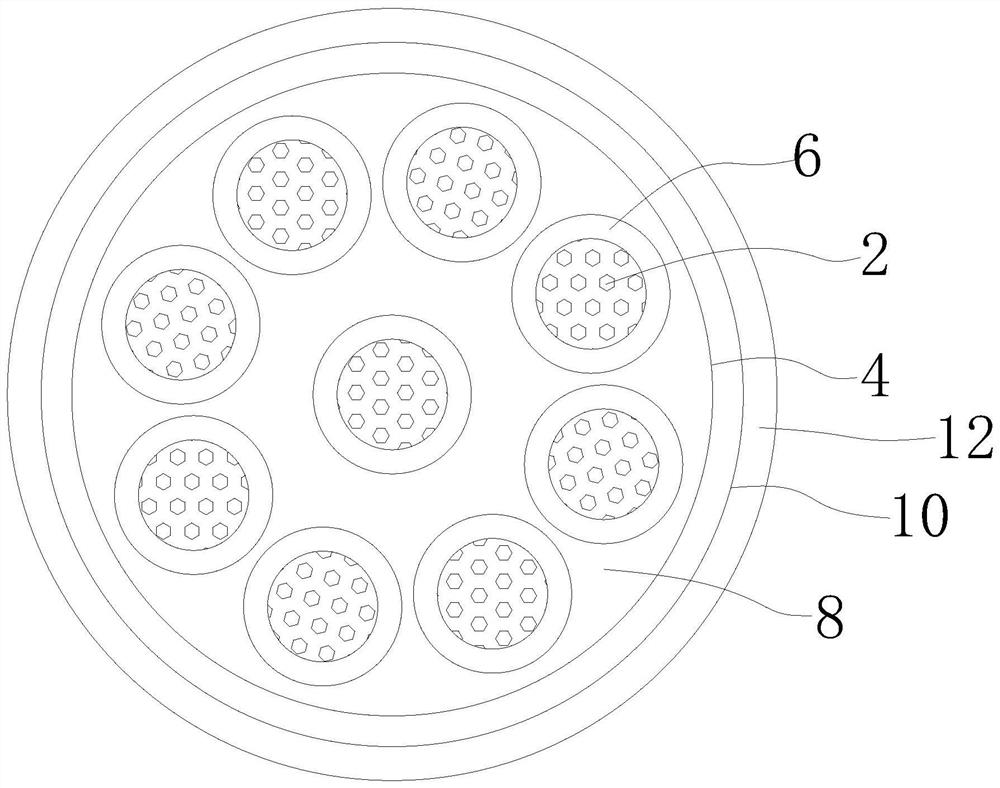

[0054] This embodiment discloses a fan bridge cable, refer to figure 1 As shown, the cable includes a cable core 4, an EPCV insulating layer 6 and a CPE sheath layer 12. The cable core 4 has multiple groups of conductors 2 twisted with each other, and the multiple groups of conductors 2 are filled with unvulcanized CPE rubber (i.e. Filler 8), the above-mentioned conductor 2 is a stranded conductor, and the above-mentioned stranded conductor is made by twisting multiple strands of copper wire. The direction of the layer monofilament strands is opposite, and the pitch ratio of the outermost layer of the strands is 6 to 8 times.

[0055] The outer side of each conductor 2 is covered with an insulating layer 6 , and the outer side of multiple conductors 2 is wrapped with a wrapping tape 10 and then covered with a sheath layer 12 on the outer side.

[0056] The above-mentioned EPCV insulating layer 6 is formed by extruding the insulating material on the outside of the conductor 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com