Fractionating tower feed distributing structure and fractionating tower

A fractionation tower and feed technology, applied in fractionation, hydrocarbon distillation, distillation separation, etc., can solve the problems of affecting the performance of the distributor fractionation tower, not providing liquid gasification space, reducing the centrifugal gas-liquid separation effect, etc. Liquid separation and distribution effect, significant distribution effect, sufficient gas-liquid separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

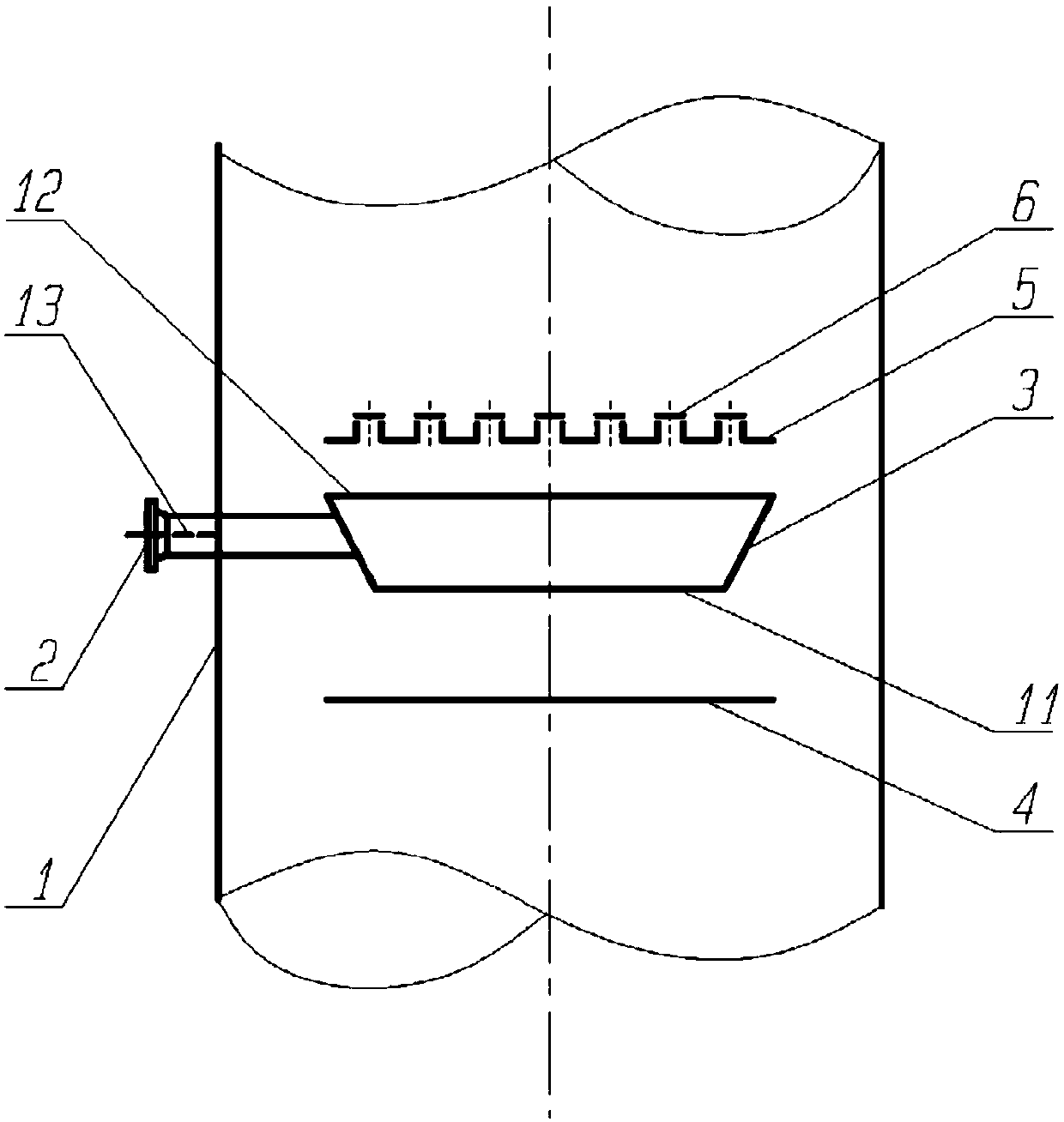

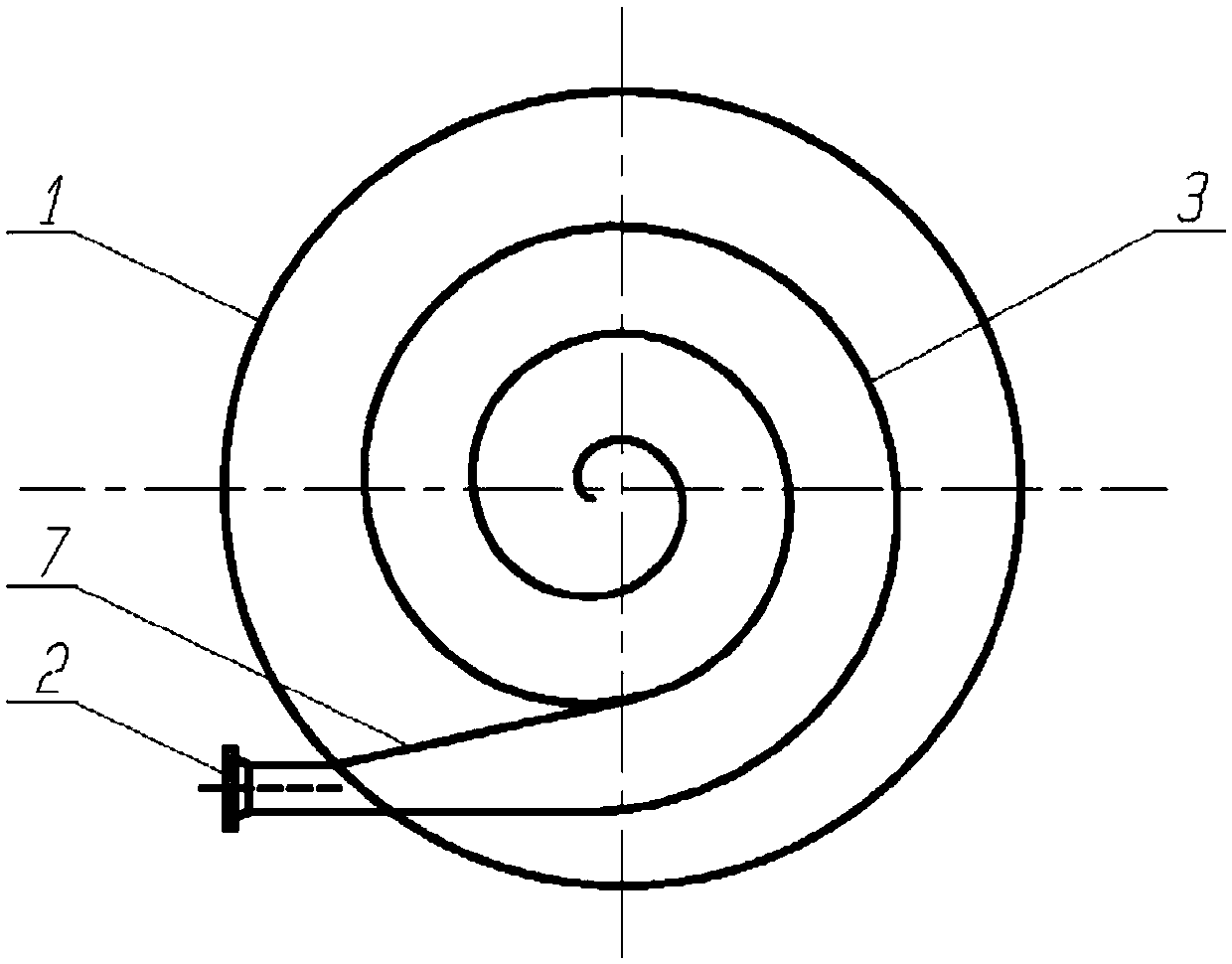

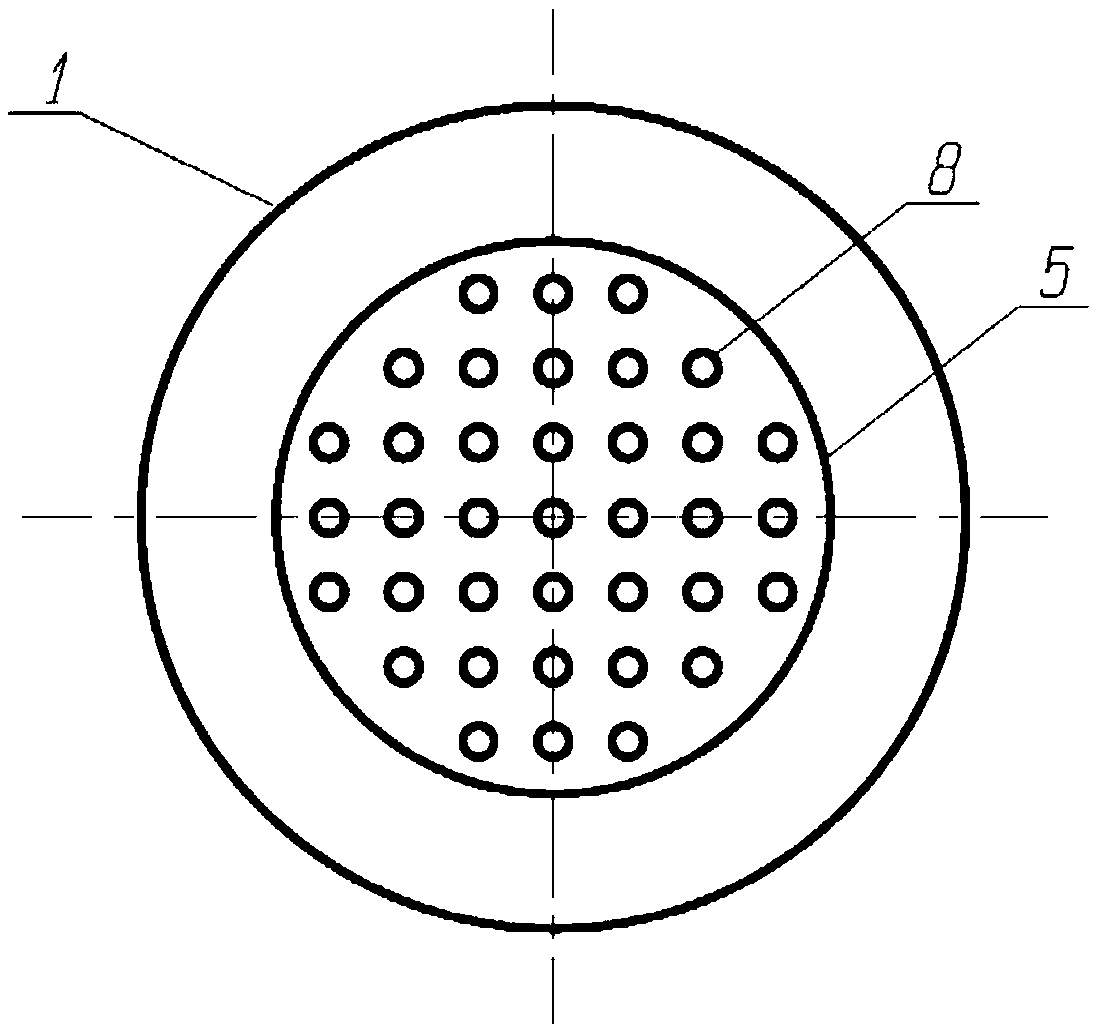

[0033] This embodiment relates to a fractionation tower, such as figure 1 and figure 2 As shown, the fractionation tower comprises: a fractionation tower shell 1, a fractionation tower feed port 2 and a fractionation tower feed distribution structure, and the fractionation tower feed distribution structure includes: a swirl plate 3 arranged inside the fractionation tower, so The swirl plate 3 communicates with the feed port 2 of the fractionation tower through the expander pipe 7; the gas distribution plate 5 arranged directly above the swirl plate 3; the liquid regasification distribution plate 4 arranged directly below the swirl plate 3.

[0034] Such as Figure 4 As shown, one end of the expanding tube 7 is a contracting end 9, and the other end is an expanding end 10. The section of the contracting end 9 is circular and is equal to the feed port 2 of the fractionation column. The section of the expanding end 10 is It is elliptical, tangent to both sides of the inlet of ...

Embodiment 2

[0041] The difference from Embodiment 1 is that the air lift cylinders 8 are arranged in a triangle on the gas distribution plate 5, such as Figure 3b As shown, the cone angle of the cone is 73°, such as Figure 5b As shown, the applicable gas-liquid ratio of the swirl plate in this embodiment is smaller than that in Embodiment 1.

[0042] Adopting the feed distribution structure of the above-mentioned fractionation tower, the gas-liquid separation effect is guaranteed, and the gas and liquid are evenly distributed on the cross-section of the tower, which provides a strong guarantee for the product separation of the fractionation tower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com