Split type forging die and die changing method

A split type, forging technology, applied in the direction of forging/pressing/hammer device, forging/pressing/hammering machine, manufacturing tool, etc. Convenience, improve the efficiency of mold change, and facilitate the effect of mold replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

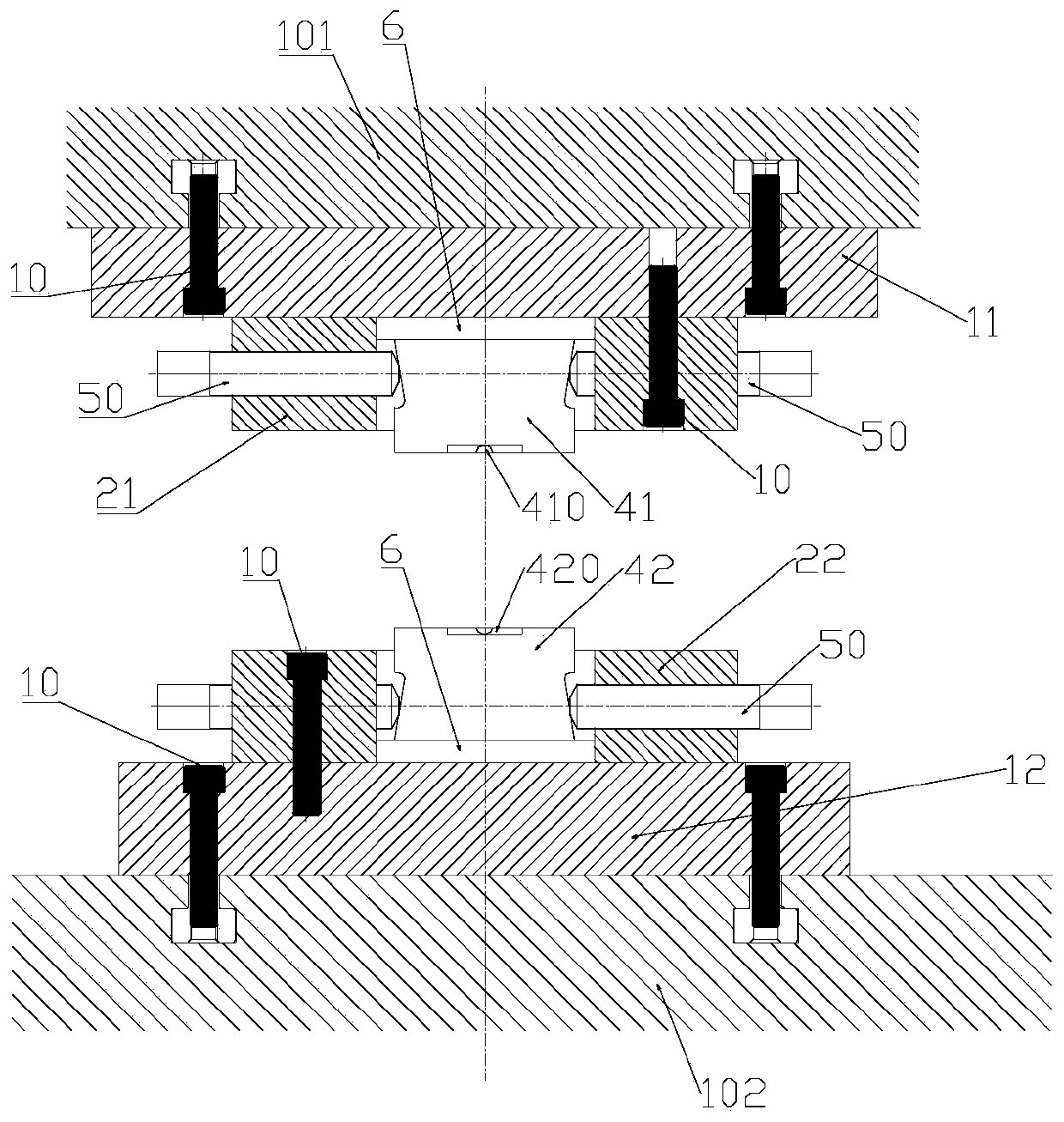

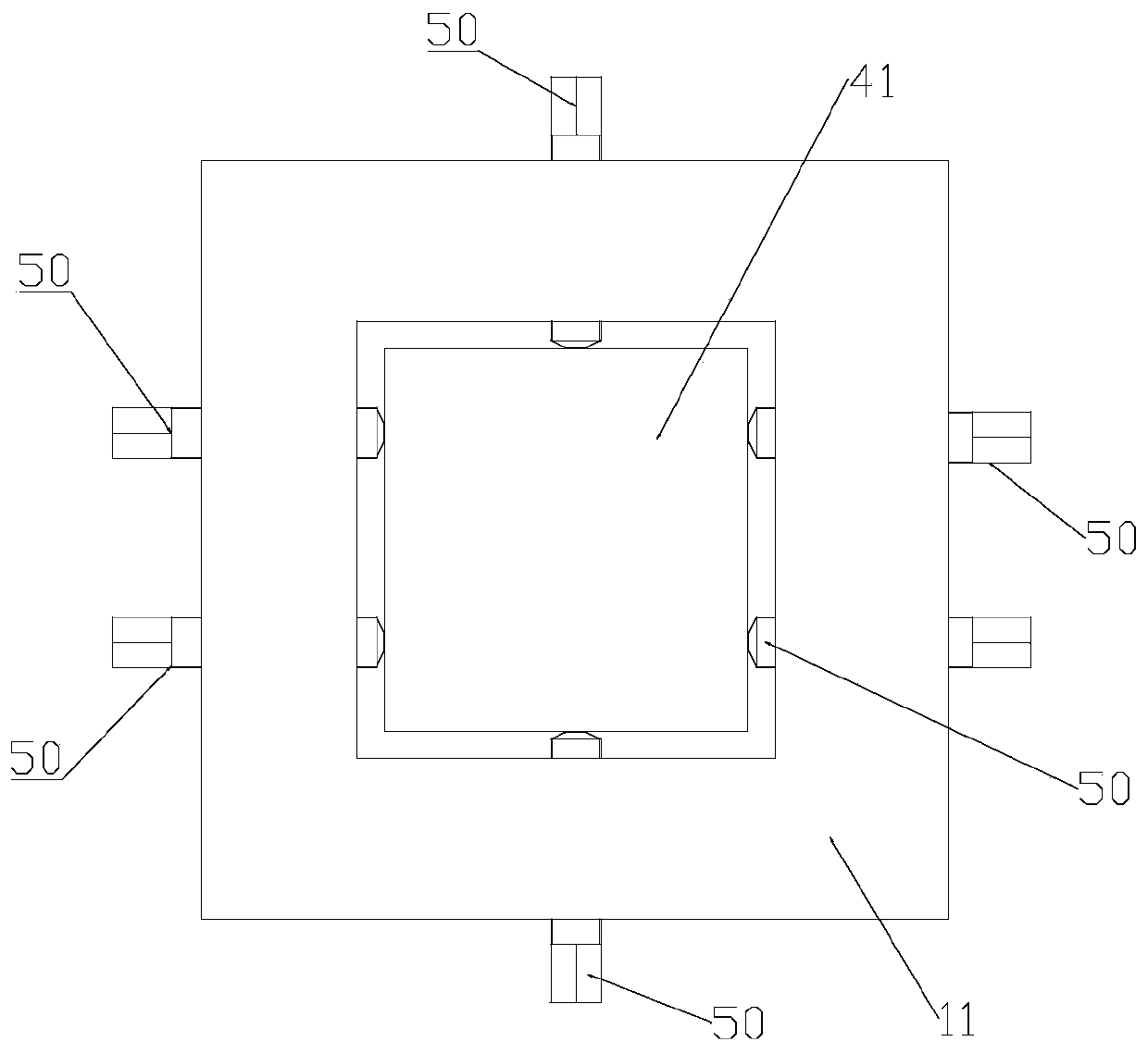

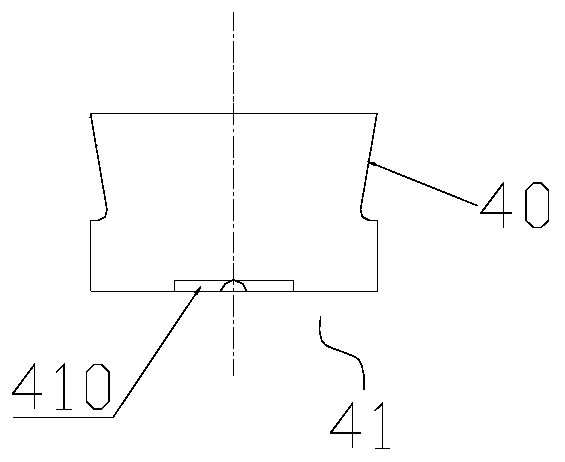

[0025] The following examples and attachments are combined Figure 1 to 3 The present invention will be further described.

[0026] A split forging die, such as figure 1 As shown, it includes a die base, a fastener, a forging die and a backing plate, the die base and the die box are screwed fixedly connected, the fastener is screwed fixedly connected to the die box, and the forging die is fixed at The inside of the mold box constitutes a forging die for quick and easy product change. In this embodiment, there are two mold bases, both of which are plate-like structures, which are an upper mold base 11 and a lower mold base 12, respectively. The upper mold base 11 is detachably installed on the upper workbench of the forging equipment by screws 10 On 101, the lower die base 12 is also detachably installed on the lower workbench 102 of the forging equipment by screws 10.

[0027] There are two mold boxes, namely an upper mold box 21 and a lower mold box 22. The upper mold box 21 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com