A fully automatic pipe punching machine

A punching machine, fully automatic technology, applied in the field of machinery, can solve the problems of low punching efficiency, reduced work efficiency, wide area, etc., and achieve the effect of effective feeding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

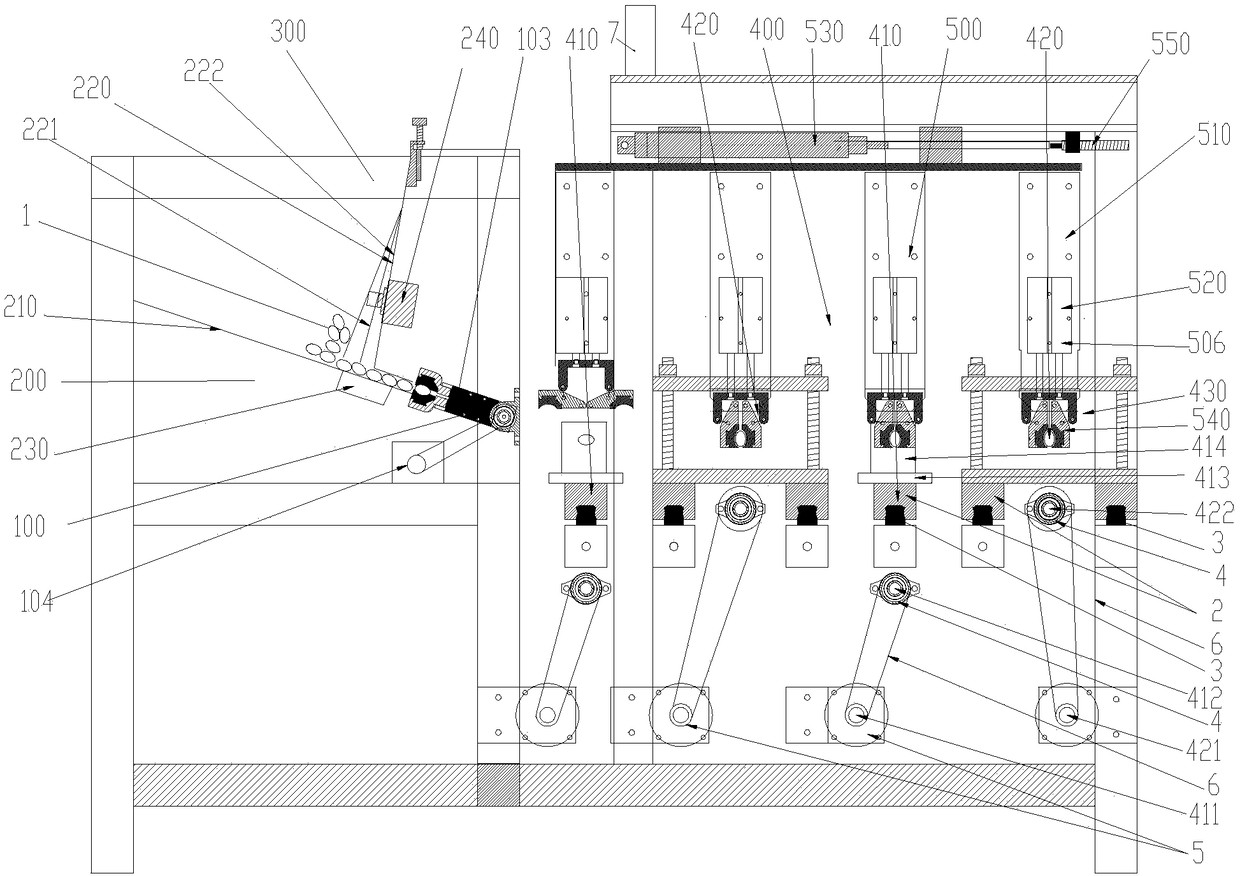

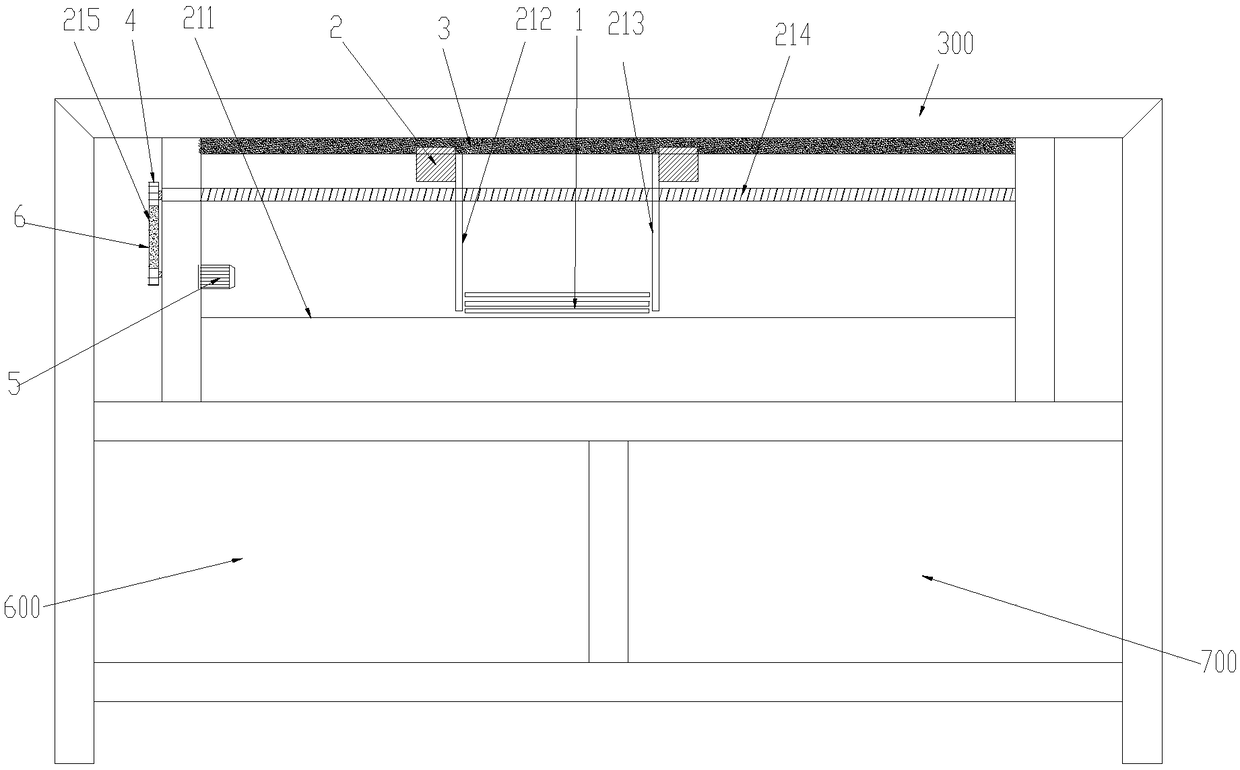

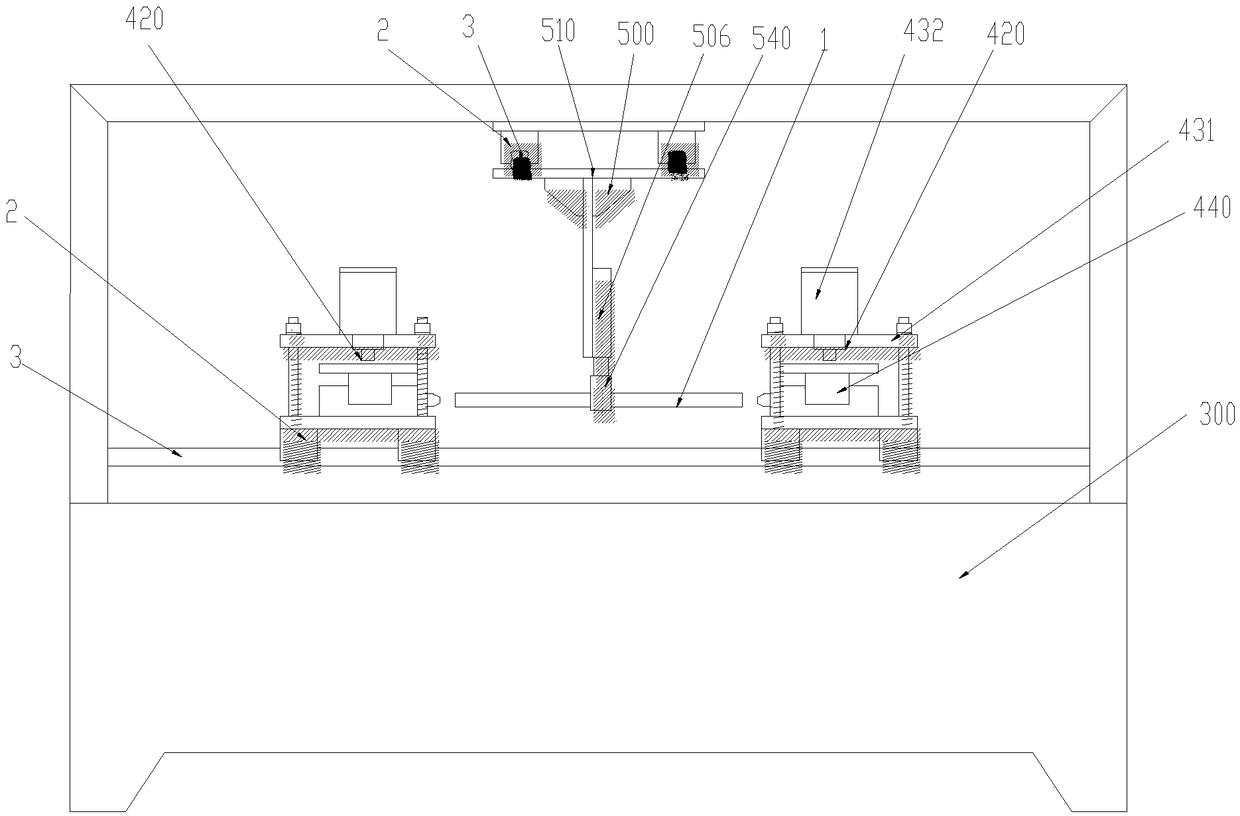

[0034] Such as Figure 1~6As shown, a fully automatic pipe punching machine includes a frame 300, a discharge mechanism 200 arranged on the frame 300, a turning mechanism 100 for moving the pipe on the discharging mechanism 200, and the turning mechanism 100 is used in conjunction with The forming mechanism 400 for punching and forming the pipe material, the conveying mechanism 500 for moving the pipe material on the forming mechanism 400, the hydraulic control system 600 provided on the frame 300 to provide power for the forming mechanism, and the electrical control system for controlling each mechanism. Control system 700, the pipes are arranged through the discharging mechanism 200, the pipes are moved from the discharging mechanism 200 to the forming mechanism 400 through the turning mechanism 100 for stamping and forming, and the processed pipes are sequentially forwarded on the forming mechanism 400 through the conveying mechanism 500 Mobile molding; the discharge mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com