Rivet-pressing and bending universal machine

A general-purpose machine and bending die technology, applied in the field of sheet metal, can solve the problems of increasing the operating cost of the enterprise, unfavorable enterprise development, single function, etc., and achieve the effect of quick and convenient replacement of the mold, saving time, and reducing the vacancy rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

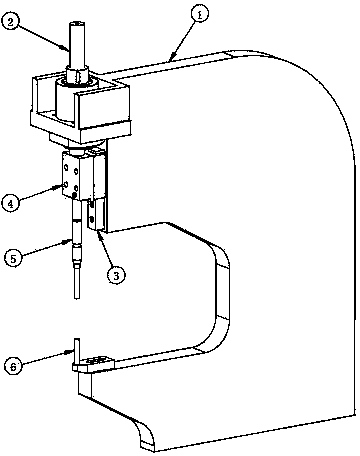

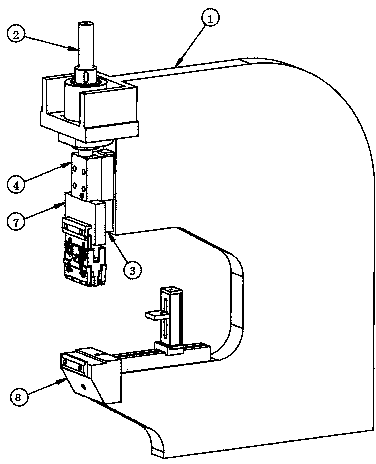

[0016] Such as Figure 1-4 Shown is the structural representation of the present invention's riveting and bending universal machine. Platforms 6 and 8, the ball screw 2 is arranged on the upper end of the frame, which is connected with the servo motor, the guide rail 3 is a long metal strip, fixed on the frame at the lower end of the ball screw 2, and the slider is connected The seat 4 is connected to the lower end of the ball screw 2, and the side is installed on the guide rail 3. When the ball screw 2 is working, the slider connecting seat 4 can slide vertically up and down on the guide rail 3 under the push of the ball screw pair 2. Make it accurately cooperate with the lower mold installed on the workbench for functional operation.

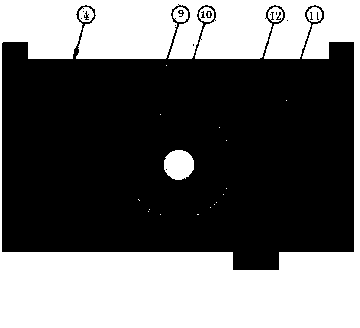

[0017] The upper part of the mold 5, 7 has a columnar connecting portion 9, and can be connected with the mounting hole 10 at the lower end of the slider connecting seat 4, and the molds 5, 7 are fixed on the The lower end of the slider conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com