Peel-off milk bottle cap

A tear-off, milk technology, applied in the field of bottle caps, can solve the problems of cap damage, lack of material in the tear-off part, increase the difficulty of mold design, etc., and achieve the effects of increasing sealing, not slipping, and increasing the convenience of tearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

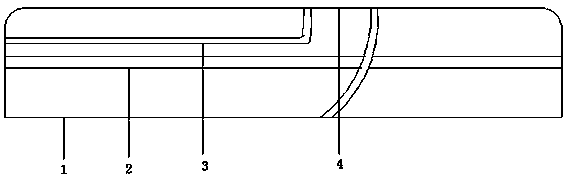

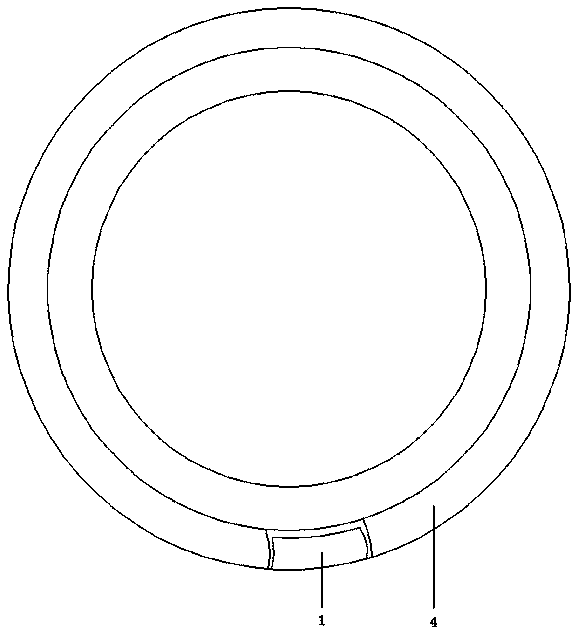

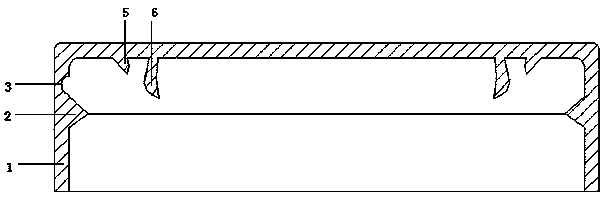

[0017] A tear-off type milk bottle cap, comprising a cover body 1 and a tear-off button 4, characterized in that: a convex ring 2 is provided in the middle of the inner wall of the cover body 1, and a tearing indentation 3 is provided on the cover body 1 on the upper part of the convex ring 2, One end of the tearing dent 3 is provided with a tearing button 4, and the tearing button 4 is arranged on the edge position of the upper surface of the cover body 1, and the top inner surface of the cover body 1 is provided with a fixing ring 5, and the top inner surface of the cover body 1 close to the fixing ring 5 A sealing ring 6 is provided. The sealing ring 6 is a conical structure with a narrow upper end and a wider lower end. The convex ring 2 is arranged in sections, and the tear button 4 is sheet-shaped, which can be set into various shapes according to requirements. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com