Embedded fixed type seamless high manganese steel frog structure

A high-manganese steel, embedded technology, used in switches, roads, tracks, etc., can solve the problems of poor overall strength, difficulty in preventing the core from moving up and down, and difficulty in meeting the strength requirements of heavy-duty railways for frogs. Achieve the effect of improving the overall strength, improving the quality of a single piece, and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

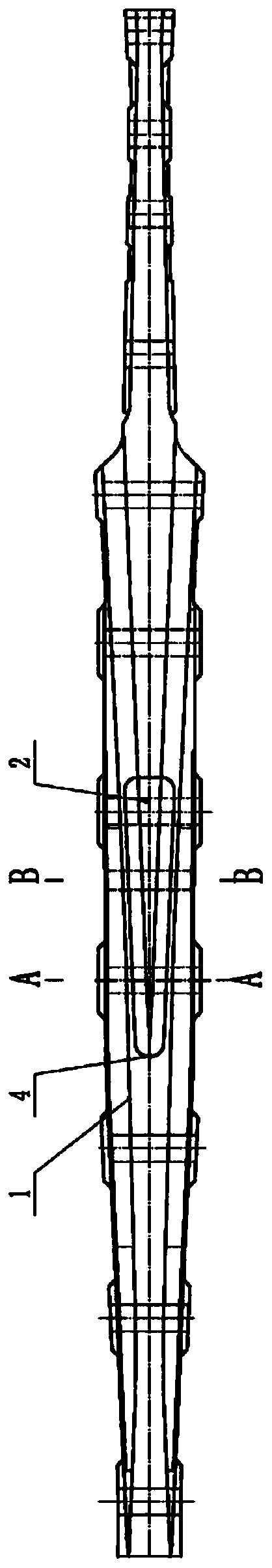

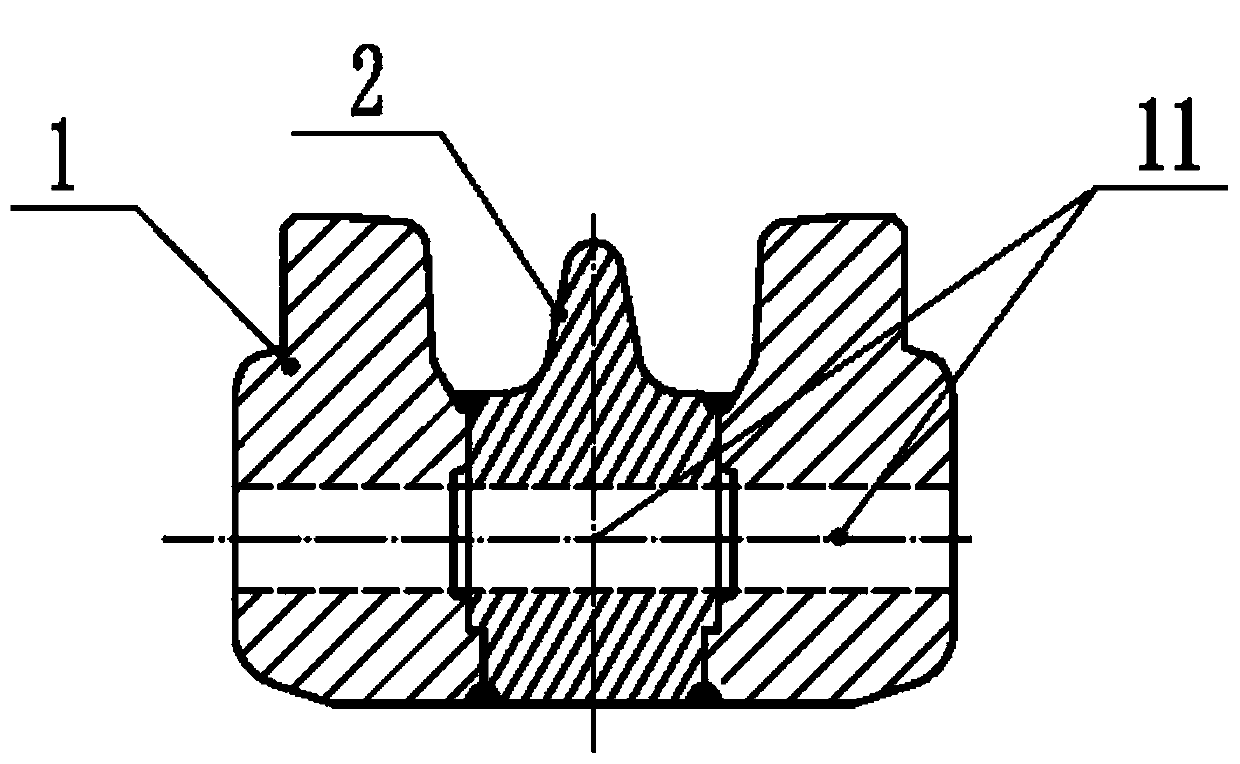

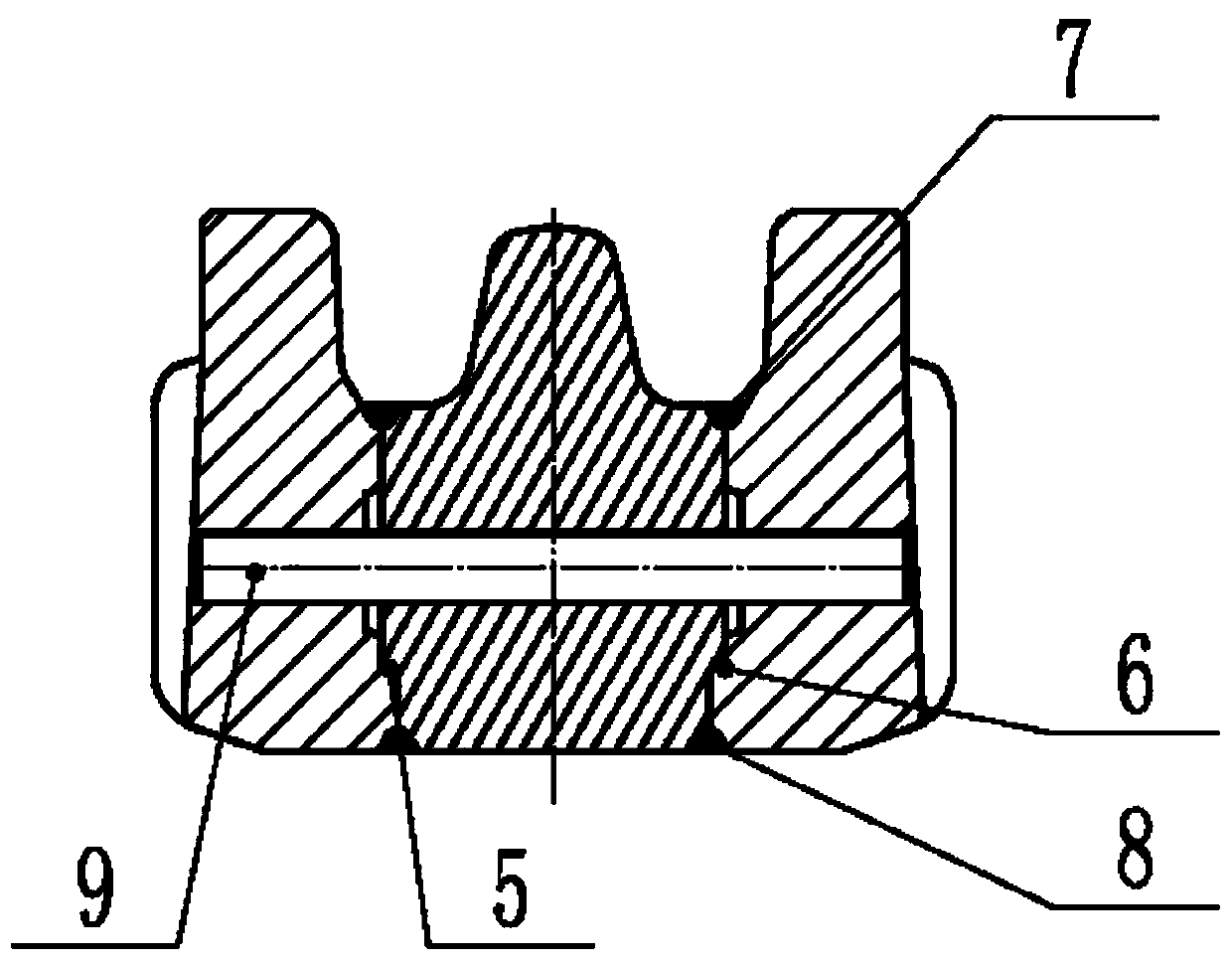

[0027] Attached below Figure 1-8 The present invention is described in detail with specific examples.

[0028] An embedded and fixed seamless high manganese steel frog structure, comprising a high manganese steel frog body 1 and a wear-resistant core rail mosaic block 2, the high manganese steel frog body 1 fork core rail wearable section has an upper and lower The through inner cavity 3, the length of the inner cavity 3 is slightly longer than the length of the wear-resistant section of the fork rail and the starting end is the theoretical tip 4 of the fork rail, the width of the inner cavity 3 gradually increases from the beginning and is always slightly larger than this area The width of the bottom of the section fork core rail, the lower part of the two side walls of the inner cavity 3 is symmetrically formed with bearing shoulders 5; Adaptation, the rail type of the wear-resistant core rail mosaic block 2 is consistent with the rail type of the missing section of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com