Integrated liquid supply system transportation device and control system thereof as well as integrated liquid supply device

The technology of a transportation device and a control system is applied in the field of mining equipment in fully mechanized mining face, and can solve the problems of easy rope breakage, safe transportation of slippery slopes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

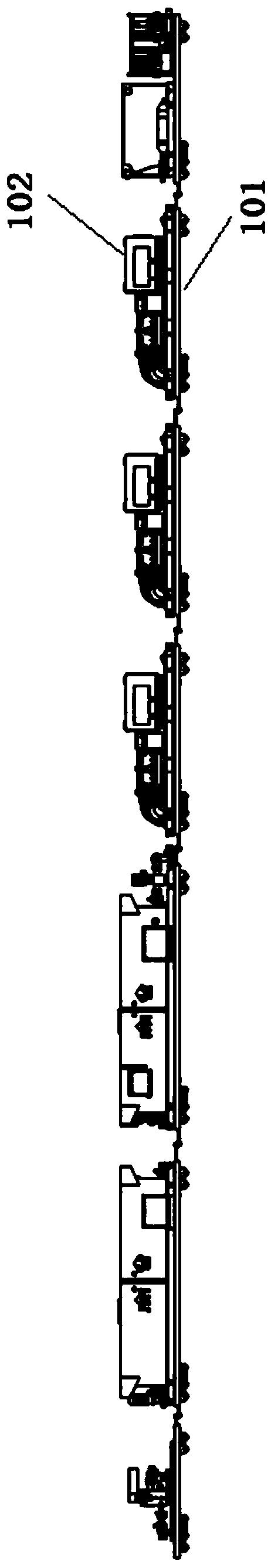

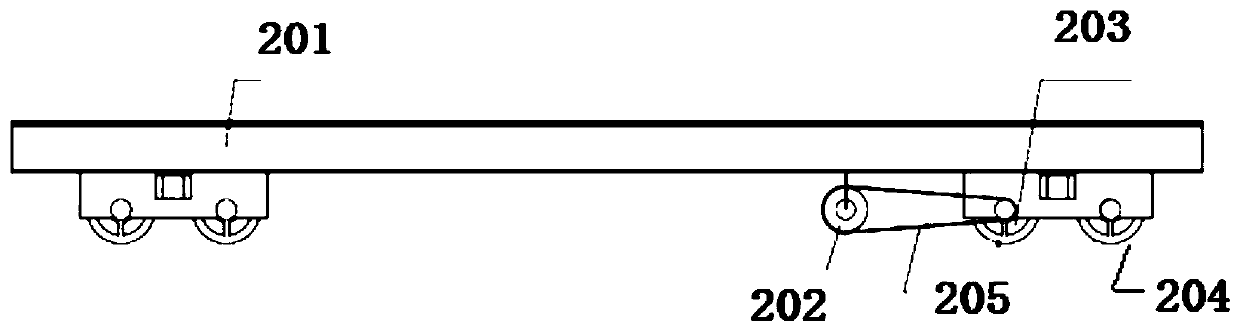

[0037] This embodiment provides an integrated liquid supply system transportation device, combined with figure 1 , figure 2 and image 3 As shown, it includes a plurality of flat car assemblies 101 connected in sequence, and each said flat car assembly 101 includes:

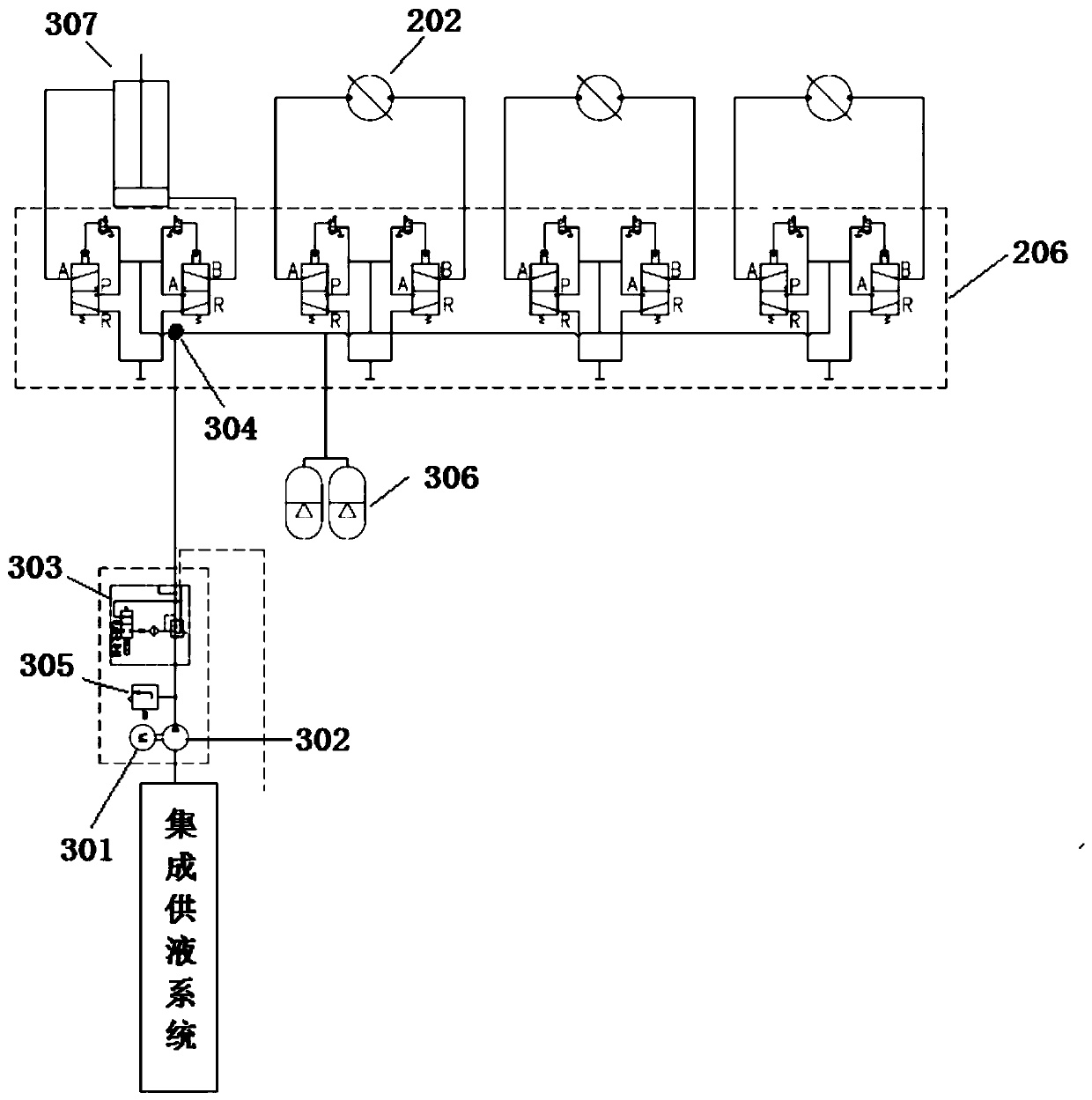

[0038]Body body 201, which has a receiving surface for carrying integrated liquid supply system components 102; a medium transmission passage, whose first end is connected to the medium outlet of the integrated liquid supply system through a valve assembly, and whose second end is connected to the medium collection point 304 , the controlled end of the valve assembly communicates with the host computer, the valve assembly receives the control command sent by the host computer to achieve conduction or cut-off, the valve assembly conducts; the reversing valve 206 (from the figure It can be seen that for the reversing valve, its number should be the same as the sum of the numbers of the hydraulic motor 202 and th...

Embodiment 2

[0050] This embodiment provides a control system for an integrated liquid supply system transportation device, such as Figure 5 As shown, it includes the transportation device of the integrated liquid supply system and the upper computer 501, wherein the upper computer 501 is used to communicate with the hydraulic support controller 503 to obtain the liquid supply parameters of the hydraulic support, and obtain the integrated supply according to the liquid supply parameters. The theoretical moving speed of the liquid system, according to the theoretical moving speed, control commands are generated and sent to the controlled end of the valve assembly 502 of the transportation device; the controlled end of the valve assembly 502 receives the control sent by the host computer 501 Instructions are turned on or off according to the control instructions to drive the flatbed truck assembly 101 to move so as to control the transportation device to move at the theoretical moving speed....

Embodiment 3

[0056] This embodiment provides an integrated liquid supply equipment, including the integrated liquid supply system and the control system of the transport device of the integrated liquid supply system described in any solution in Embodiment 2, wherein the different components of the integrated liquid supply system are sequentially It is arranged on the body bodies of different flatbed truck components of the transportation device.

[0057] By controlling the moving speed of the transportation device through the control system, it can ensure that the integrated liquid supply system provides medium for each hydraulic support cylinder according to the set liquid supply demand. At the same time, since the moving process of the transportation device is to supply liquid to the hydraulic motor through the integrated liquid supply system, the drive output shaft of the hydraulic motor provides power for the driving wheel to drive the flatbed truck assembly to move, thus effectively av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com