Multi-channel ball valve structure, electric ball valve and application of electric ball valve

An electric ball valve, multi-channel technology, applied in the direction of multi-way valve, valve shell structure, valve details, etc., can solve the problems that affect the development prospects of deep diving equipment, unsatisfactory sealing effect, inconvenient operation, etc., to achieve light weight, valve Compact structure and improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

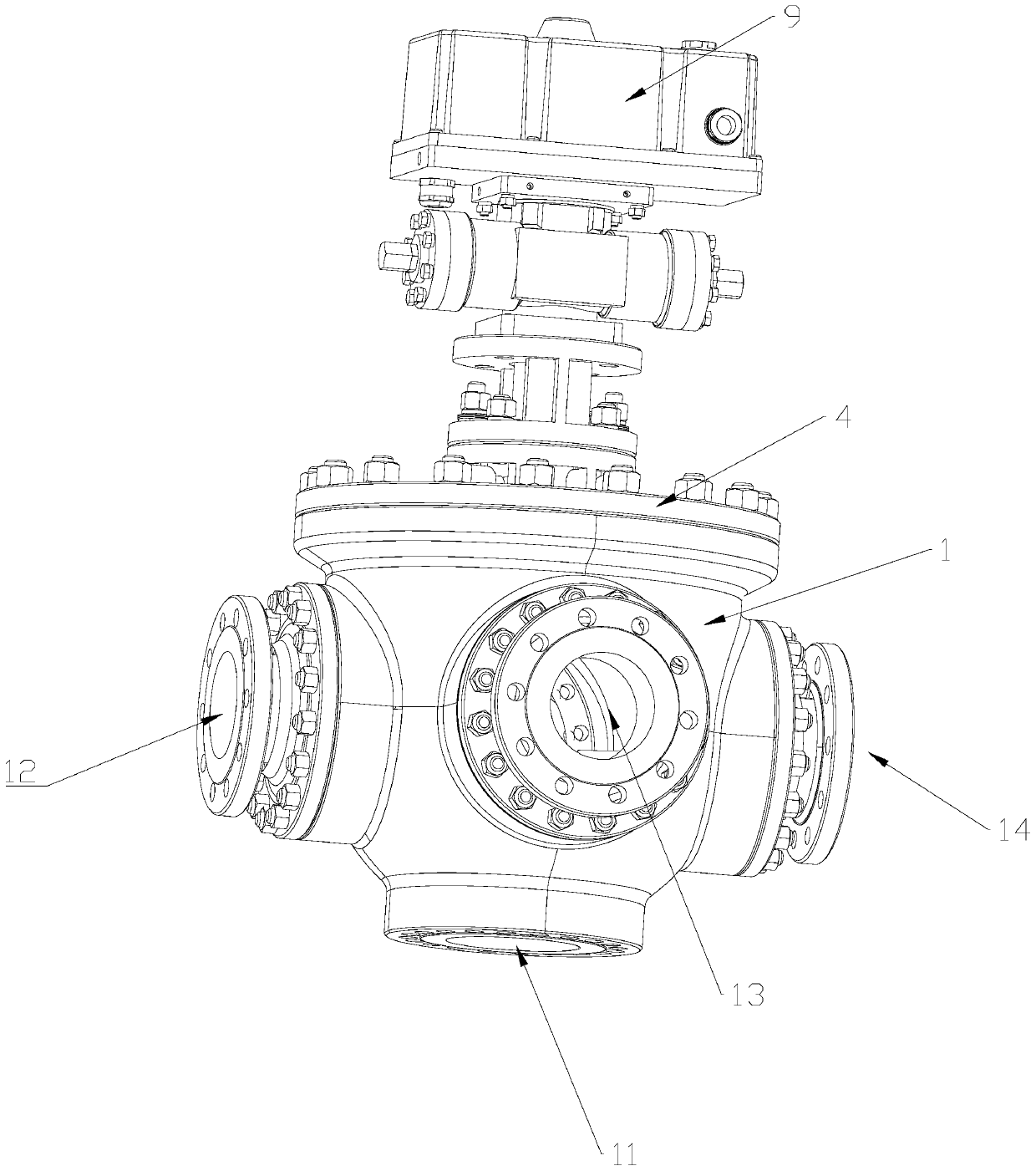

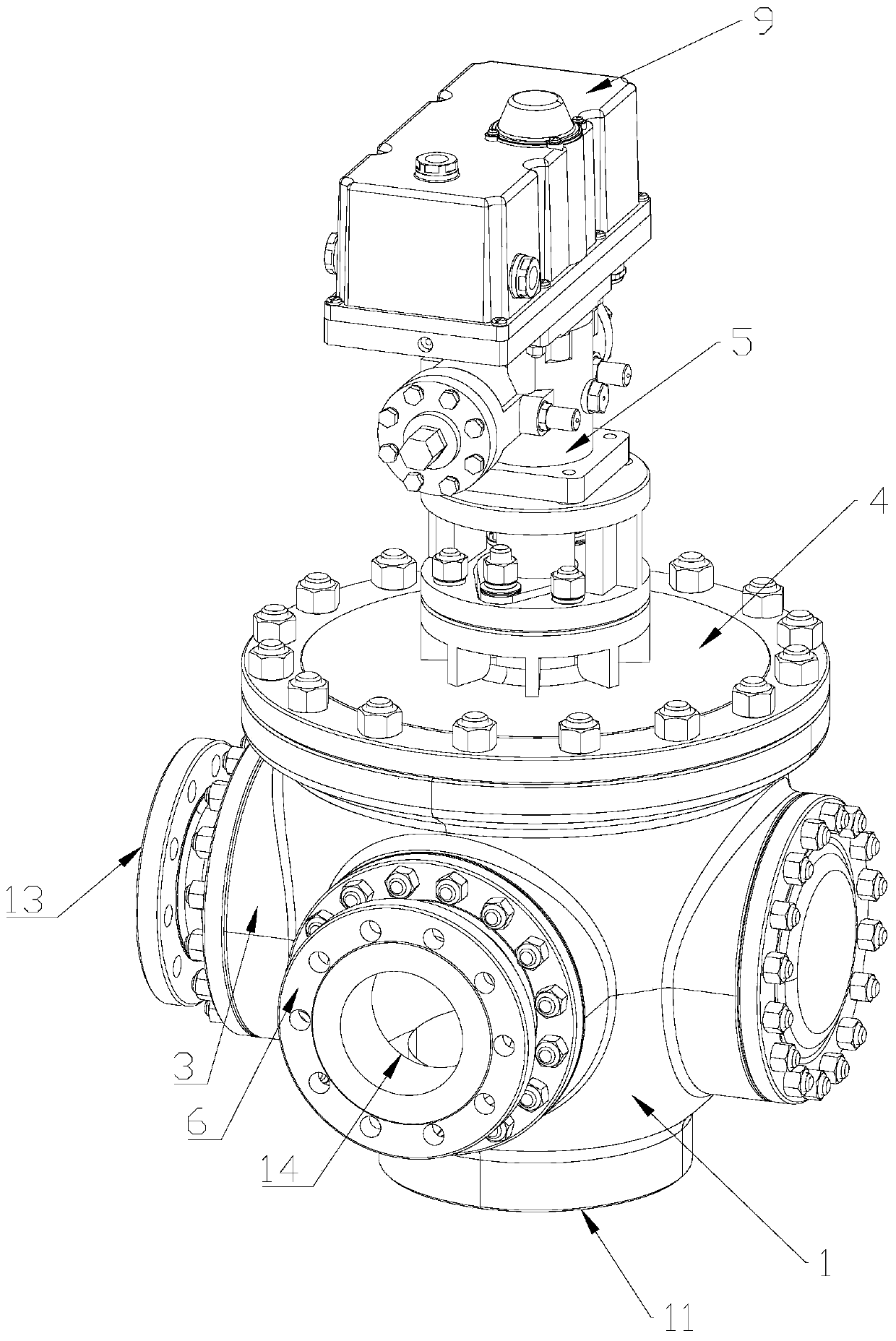

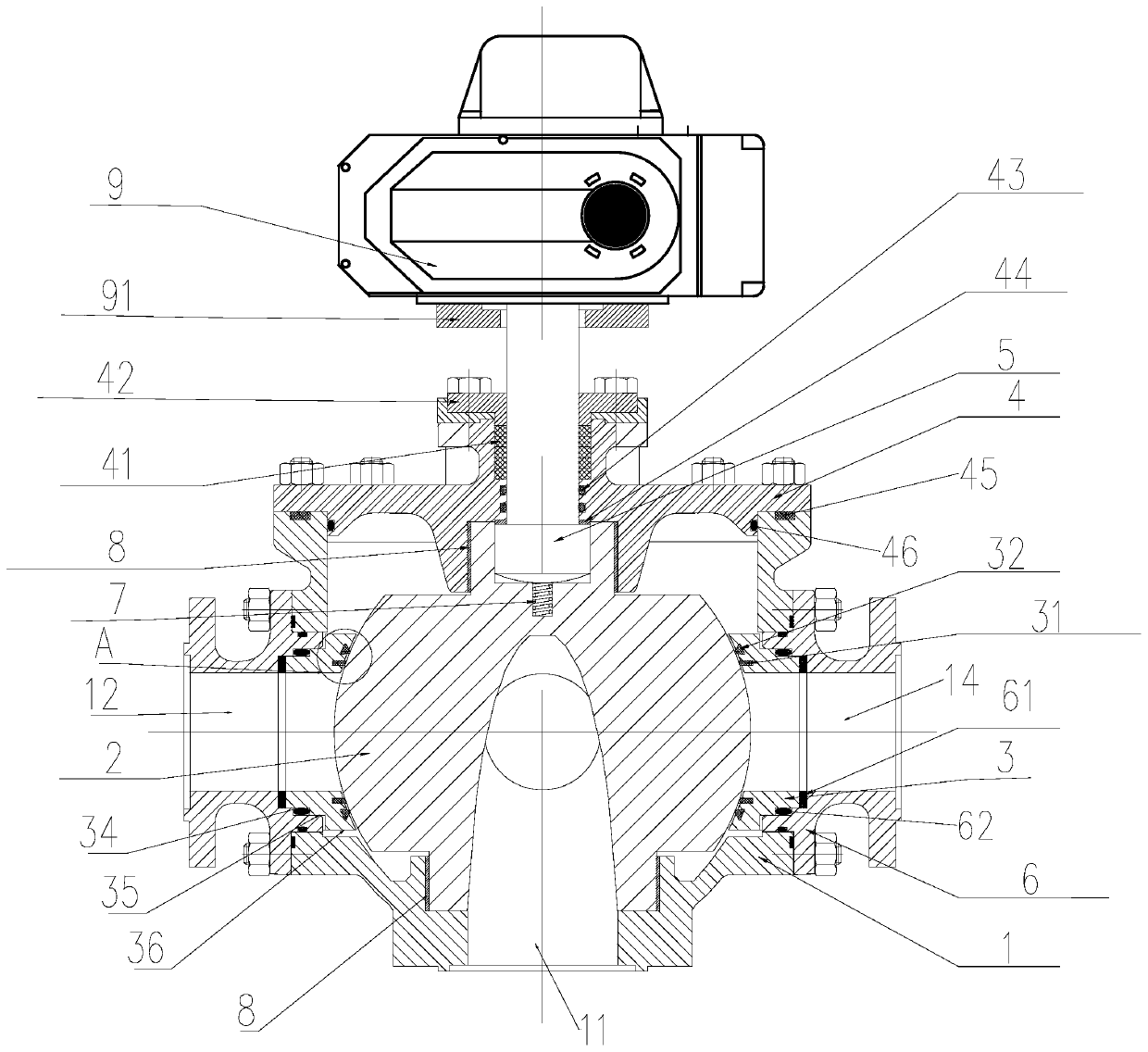

[0037] Such as Figure 1~5 As shown, the multi-channel ball valve structure of the present invention includes a valve body 1, a valve ball 2 arranged in the valve body 1, and a valve cover 4 for closing the valve body 1, and the upper end of the valve ball 2 is connected with The valve stem 5 runs through the valve cover 4; the valve ball 2 is driven to rotate by rotating the valve stem 5, so as to realize the opening and closing of the valve.

[0038] The valve body 1 is provided with inlet 11, inlet 2 12, outlet 13 and outlet 2 14 connected with other pipelines; the inlet 11 is arranged on the bottom wall of the valve body 1 for connecting the feed pipe The inlet and outlet two 12, the outlet one 13 and the outlet two 14 are arranged on the side wall of the valve body 1 for connecting the discharge pipe or the shunt pipe.

[0039] The side wall of the valve ball 2 is provided with a second channel port, a third channel port, a fourth channel port, a fifth channel port, and ...

Embodiment 2

[0044] This embodiment is improved on the basis of Embodiment 1. Specifically, the ball valve also includes a valve seat 3 arranged in the valve body 1, and the valve seat 3 is located at both ends of the valve ball 2, so A sealing seat 31 and a triangular ring sealing seat 32 are provided between the valve seat 3 and the valve ball 2 to realize the sealing between the valve seat 1 and the valve ball 2 .

[0045] Specifically, one end of the sealing seat 31 is arranged on the valve seat 3, and the end surface of the other end is arc-shaped, and fits in an arc shape with the outer wall of the valve ball 2, so that the other end of the sealing seat 31 is in contact with the valve ball. 2. The outer wall fits against each other to realize the first seal between the valve seat 1 and the valve ball 2. In this embodiment, the sealing seat 31 is made of polytetrafluoroethylene glass fiber material.

[0046] Specifically, the bottom end of the triangular ring sealing seat 32 is arrang...

Embodiment 3

[0049] This embodiment is improved on the basis of the second embodiment. Specifically, the ball valve also includes connecting flanges 6 arranged at the inlet 11, the second inlet 12, the first outlet 13 and the second outlet 14. external piping.

[0050] The end surface of the valve seat 3 is stepped, and the connection between the outermost end surface of the valve seat 3 and the connection flange 6 is provided with a metal graphite winding gasket 61 for sealing. The valve seat 3 includes a first stepped surface 34 , a second stepped surface 35 , and a third stepped surface 36 , and a second sealing ring 62 is provided at the connection between the first stepped surface 34 and the connecting flange 6 .

[0051] Therefore, the valve seat 3 and the connecting flange 6 of the present invention are double-sealed through the metal graphite wound gasket 61 and the second sealing ring 62 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com