An ultrasonic pulsating heat pipe radiator with thermoelectric power generation drive and temperature warning

A technology of pulsating heat pipes and thermoelectric power generation, which is applied in the direction of generators/motors, indirect heat exchangers, electric solid devices, etc., can solve the problems of strengthening the heat transfer performance of pulsating heat pipes, reduce starting power, ensure normal operation, and be installed and used convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

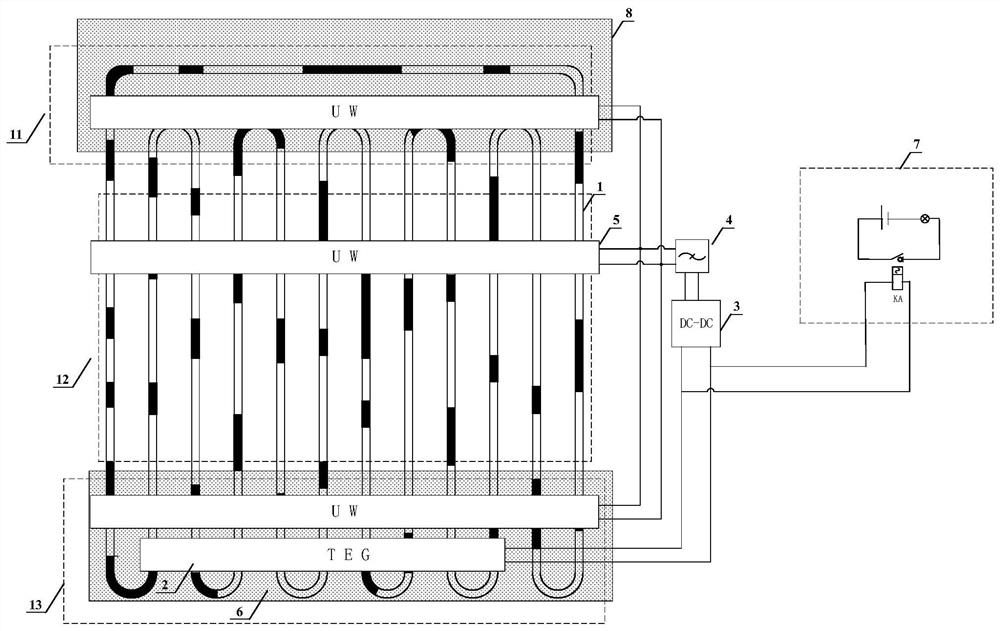

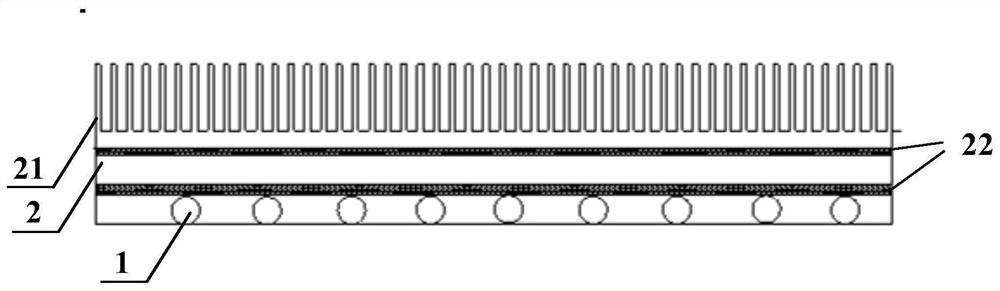

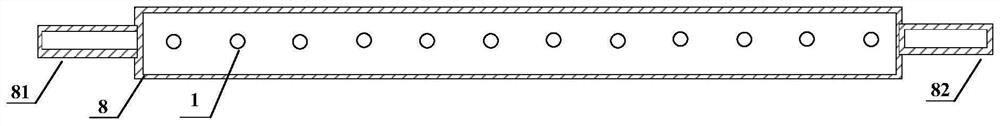

[0025] Such as figure 1 , figure 2 As shown, the ultrasonic pulsating heat pipe radiator with thermoelectric power generation drive and temperature early warning described in this embodiment includes a pulsating heat pipe 1, a thermoelectric power generation chip (TEG) 2, a DC-DC converter 3, an ultrasonic drive circuit 4, and a piezoelectric ceramic The sheet (UW) 5 and the heat conduction plate 6, the pulsating heat pipe 1 is provided with a condensation section 11, an adiabatic section 12, and an evaporation section 13 from top to bottom.

[0026] The evaporating section 13 of the pulsating heat pipe is embedded in the groove of the heat conduction plate 6, one side of the heat conduction plate 6 is in contact with the semiconductor components, and the other side is attached with a thermoelectric power generation sheet 2, and the other s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com