Explosion loading device based on one-dimensional strain conditions and use method

A technology of loading devices and conditions, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that cannot fully reflect the mechanical response, cannot judge the ability to absorb impact energy, and does not involve one-dimensional strain loading methods, etc., to achieve reduction Experimental workload, increased measurements, effects of explosion load stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

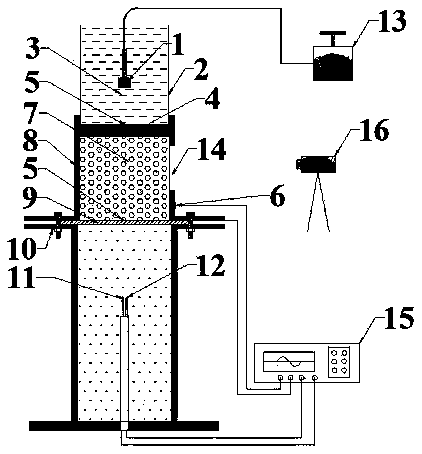

[0034] see figure 1 , the explosive loading device based on the one-dimensional strain condition of the present invention is characterized in that it comprises an explosive 1, a container 2, a medium 3, an upper metal plate 4, a sensor 5 for measuring the applied pressure, a strain gauge 6, a test piece 7, Steel pipe 8 , lower metal plate 9 , support mechanism 10 , laser interferometer 11 , sensor 12 for measuring air overpressure, detonator 13 , observation window 14 , oscilloscope 15 and high-speed camera 16 .

[0035] see figure 1 , the container 2 is equipped with a medium 3 for uniformly transmitting the explosive load to the test piece, and the explosive 1 is placed in the medium 3 , and the detonator 13 is used for detonating the explosive 1 .

[0036] join fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com