Coal spontaneous combustion program temperature control system and method utilizing microwave heating

A technology of microwave heating and coal spontaneous combustion, which is applied in the field of coal spontaneous combustion characteristics research, can solve the problems of uneven temperature distribution of coal samples, difficulty in controlling the heating rate, and long time required to achieve controllable heating rate and short time consumption , the effect of a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

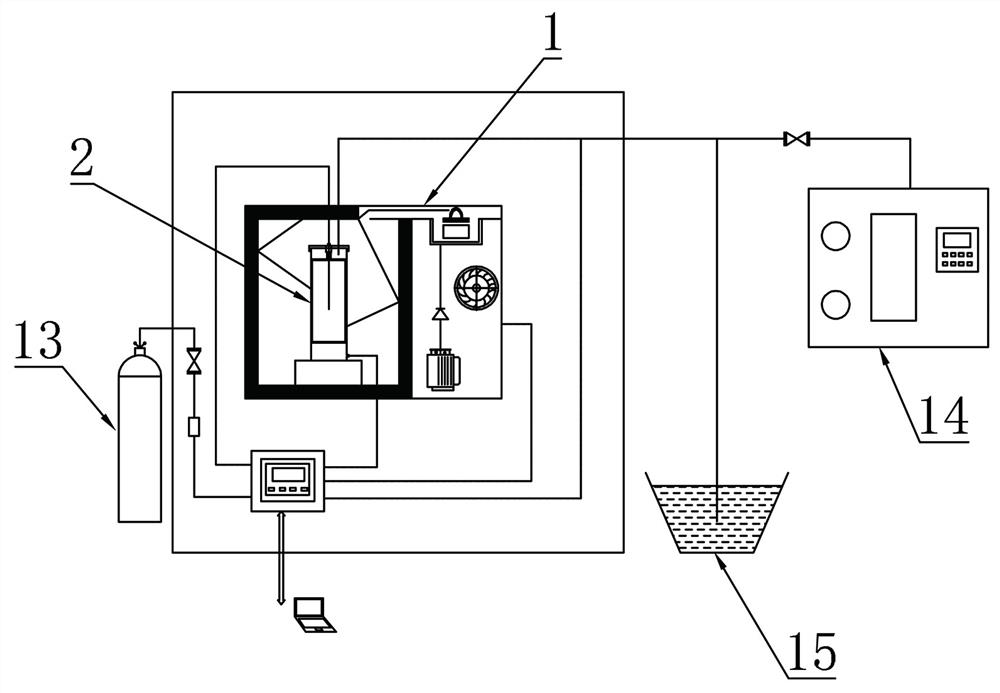

[0042] Example 1 A Coal Spontaneous Combustion Programmed Temperature Control System Utilizing Microwave Heating

[0043] Such as Figure 1 to Figure 4 As shown, this embodiment includes a heating mechanism 1, a coal sample carrying mechanism 2, an electric control mechanism, and a gas collection and analysis mechanism that cooperate with each other. In this embodiment, the microwave heating method is adopted to realize the rapid temperature rise of the coal sample, while ensuring the heating uniformity of the coal sample, it also realizes the adjustable and controllable heating rate of the coal sample.

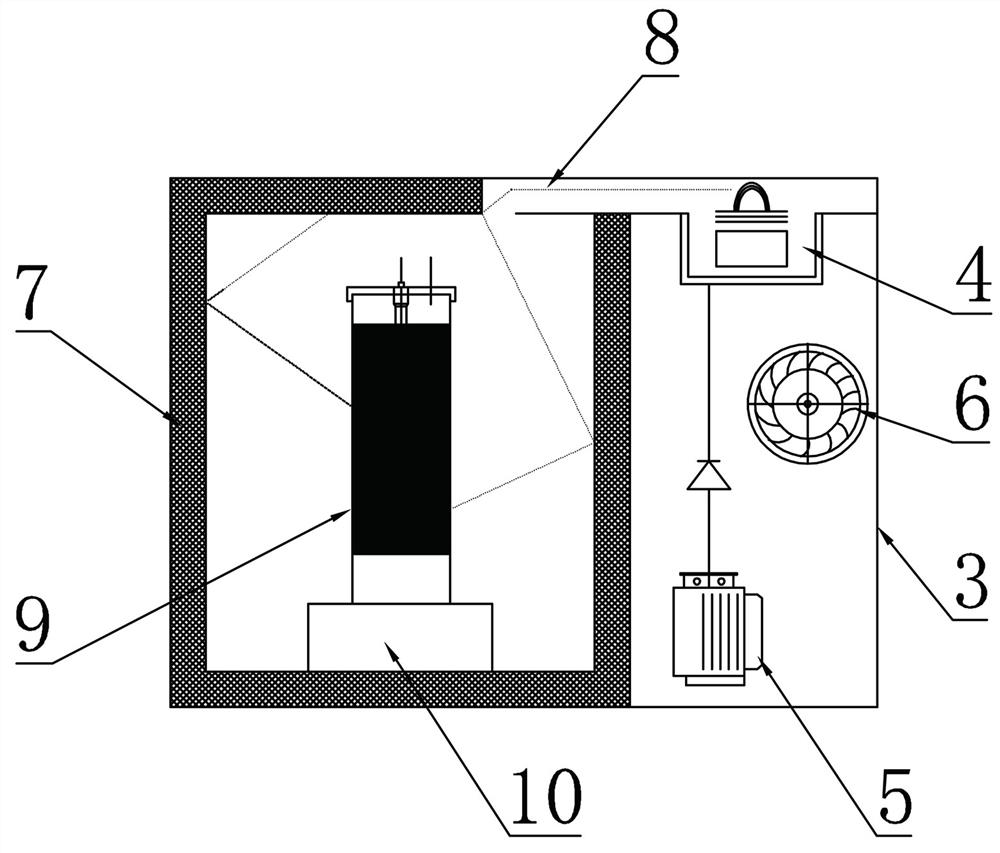

[0044] 1. Heating mechanism 1

[0045] The heating mechanism 1 is the core component of this embodiment, and is used to emit microwaves to heat the coal sample. Such as figure 2 As shown, the heating mechanism 1 includes a microwave generator, a microwave energy applicator and a microwave transmitter. Wherein, the microwave generator includes a magnetron 4 and a transforme...

Embodiment 2

[0056] Example 2 A program temperature control method for coal spontaneous combustion using microwave heating

[0057] This embodiment utilizes the coal spontaneous combustion program temperature control system as described in Embodiment 1, including the following steps carried out in sequence:

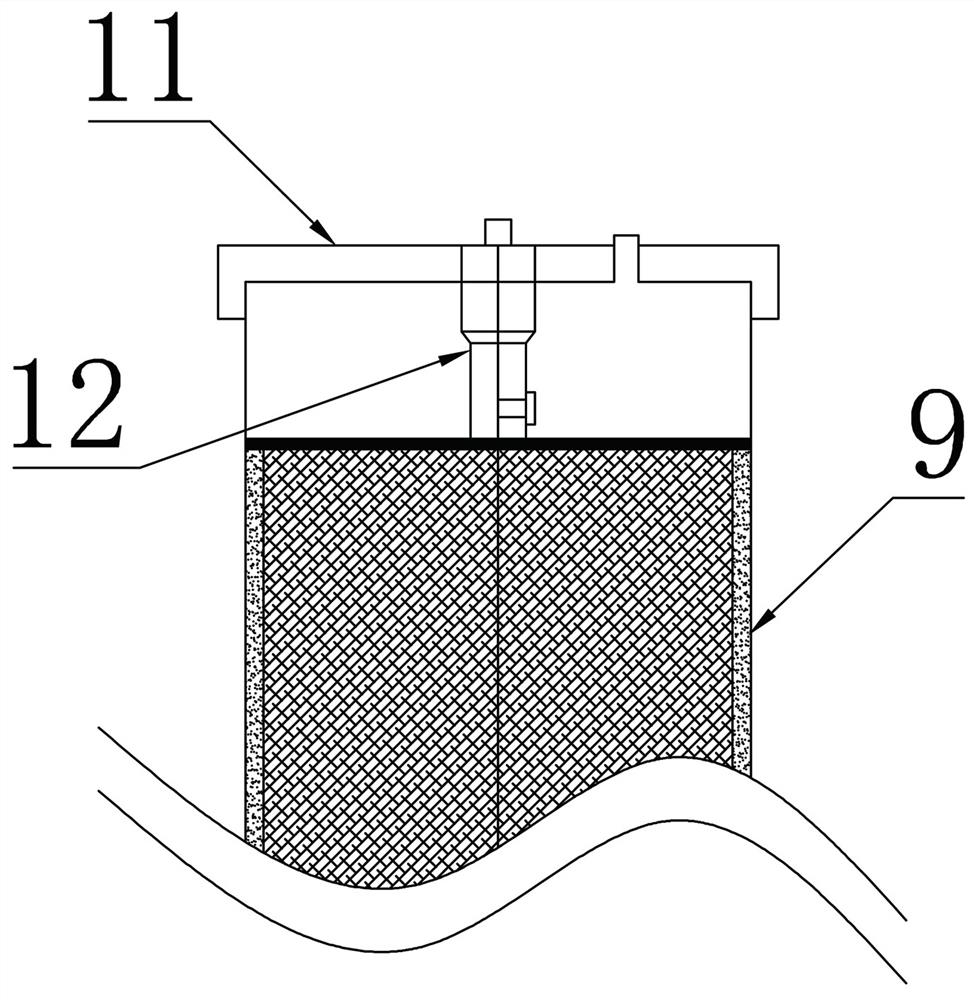

[0058] Step S1, coal sample filling

[0059] Open the door of the microwave energy applicator (that is, the resonant cavity 7), take out the coal sample tank 9, fill the coal sample broken to a certain particle size evenly into the coal sample tank 9, and then arrange a layer of asbestos mesh above the coal sample Finally, cover the end cover 11, insert the temperature sensor (ie thermocouple), and then put the coal sample tank 9 into the microwave energy applicator. At the same time, ensure that each component in the electric control mechanism and the gas chromatograph 14 can communicate with the computer in real time.

[0060] S2, programmed temperature rise

[0061] Pass the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com