Halloysite nanotube-based humidity sensor and preparation method thereof

A halloysite nanotube and humidity sensor technology, which is applied in the direction of material impedance, can solve the problems of high performance and low cost, and achieve good response recovery characteristics, fast response speed, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

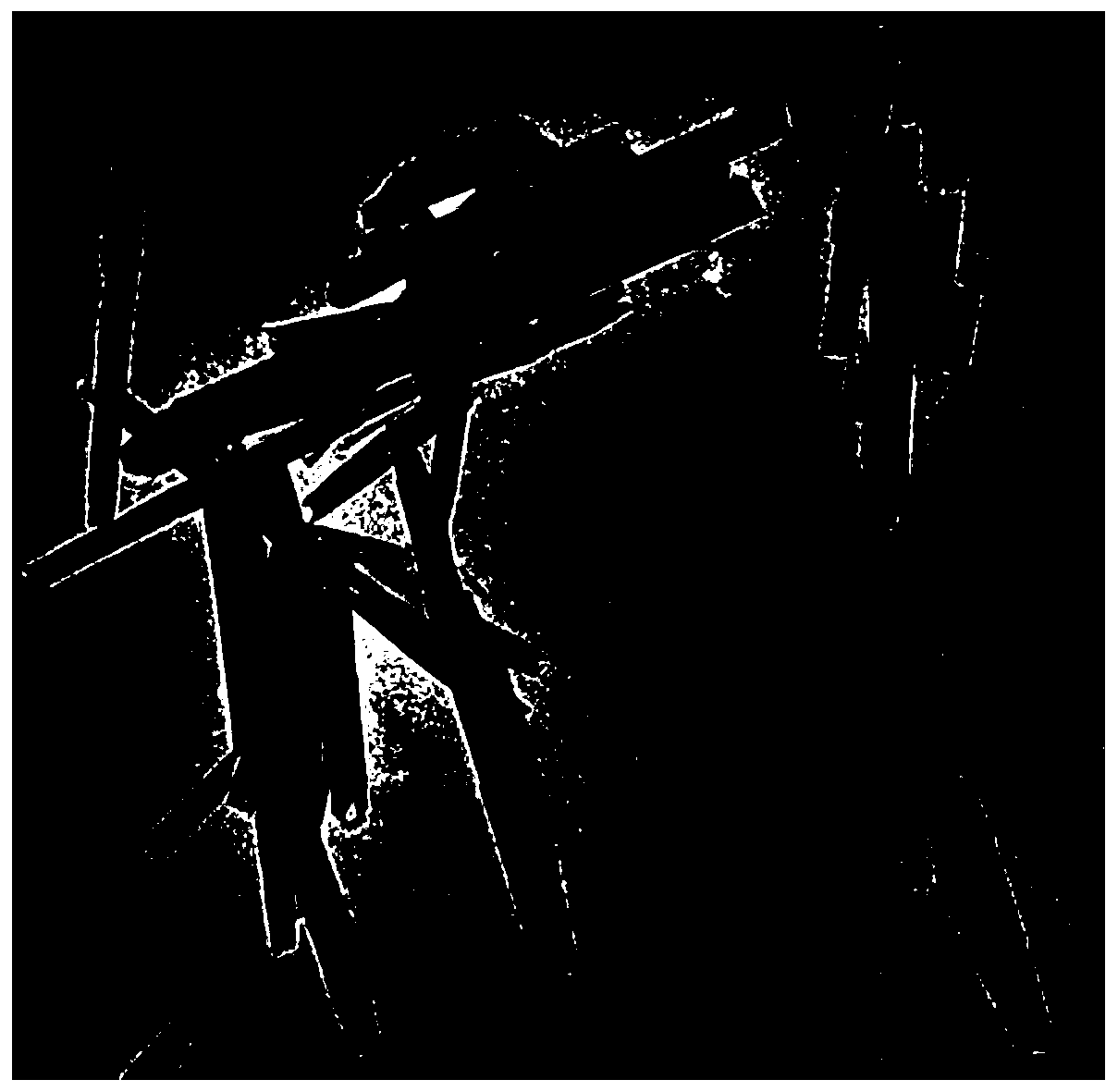

Embodiment 1

[0037] A humidity sensor based on halloysite nanotubes, comprising a substrate, the surface of the substrate contains interdigital electrodes, the substrate is coated with a humidity sensing layer, and the humidity sensing layer completely covers the interdigital electrodes , the humidity sensing layer is made of halloysite nanotubes and a solvent, the mass ratio of the halloysite nanotubes to the solvent is 1:1; the solvent is ethanol; the thickness of the humidity sensing layer The number of the interdigitated electrodes is 1 pair, and the interdigital distance of each pair of the interdigitated electrodes is 500 μm; the substrate is polyimide.

Embodiment 2

[0039] A humidity sensor based on halloysite nanotubes, comprising a substrate, the surface of the substrate contains interdigital electrodes, the substrate is coated with a humidity sensing layer, and the humidity sensing layer completely covers the interdigital electrodes , the humidity sensing layer is made of halloysite nanotubes and a solvent, the mass ratio of the halloysite nanotubes to the solvent is 1:3; the solvent is deionized water; the humidity sensing layer The thickness of the interdigitated electrode is 30 μm; the number of the interdigitated electrodes is 5 pairs, and the interdigital distance of each pair of the interdigitated electrodes is 150 μm; the substrate is aluminum oxide.

Embodiment 3

[0041] A humidity sensor based on halloysite nanotubes, comprising a substrate, the surface of the substrate contains interdigital electrodes, the substrate is coated with a humidity sensing layer, and the humidity sensing layer completely covers the interdigital electrodes , the humidity sensing layer is made of halloysite nanotubes and a solvent, the mass ratio of the halloysite nanotubes to the solvent is 1:10; the solvent is acetone; the thickness of the humidity sensing layer is 100 μm; the number of the interdigitated electrodes is 10 pairs, and the interdigital distance of each pair of the interdigitated electrodes is 50 μm; the substrate is paper.

[0042] In Embodiment 1-3, the substrate can also be one of silicon, polyetherimide or fabric;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| interdigital gap | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap