High-current coupler for storage battery car

A high-current, coupler technology, applied in the direction of electric vehicle charging technology, coupling devices, electric vehicles, etc., can solve the problems of difficult to adapt to high-current battery modules, loose sockets, inconvenient operation, etc., so that it is not easy to loosen and fall off , Reliable plugging, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

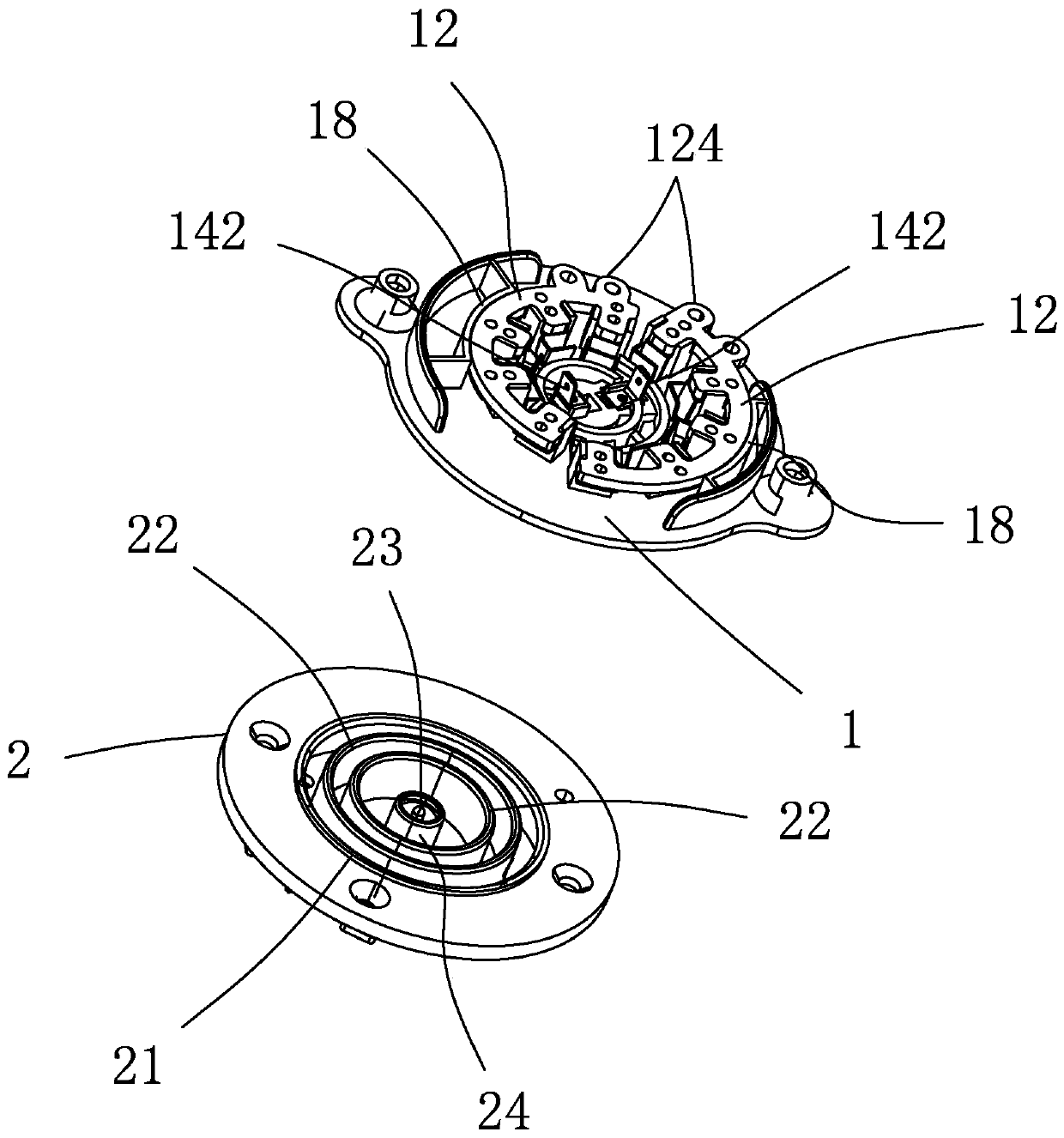

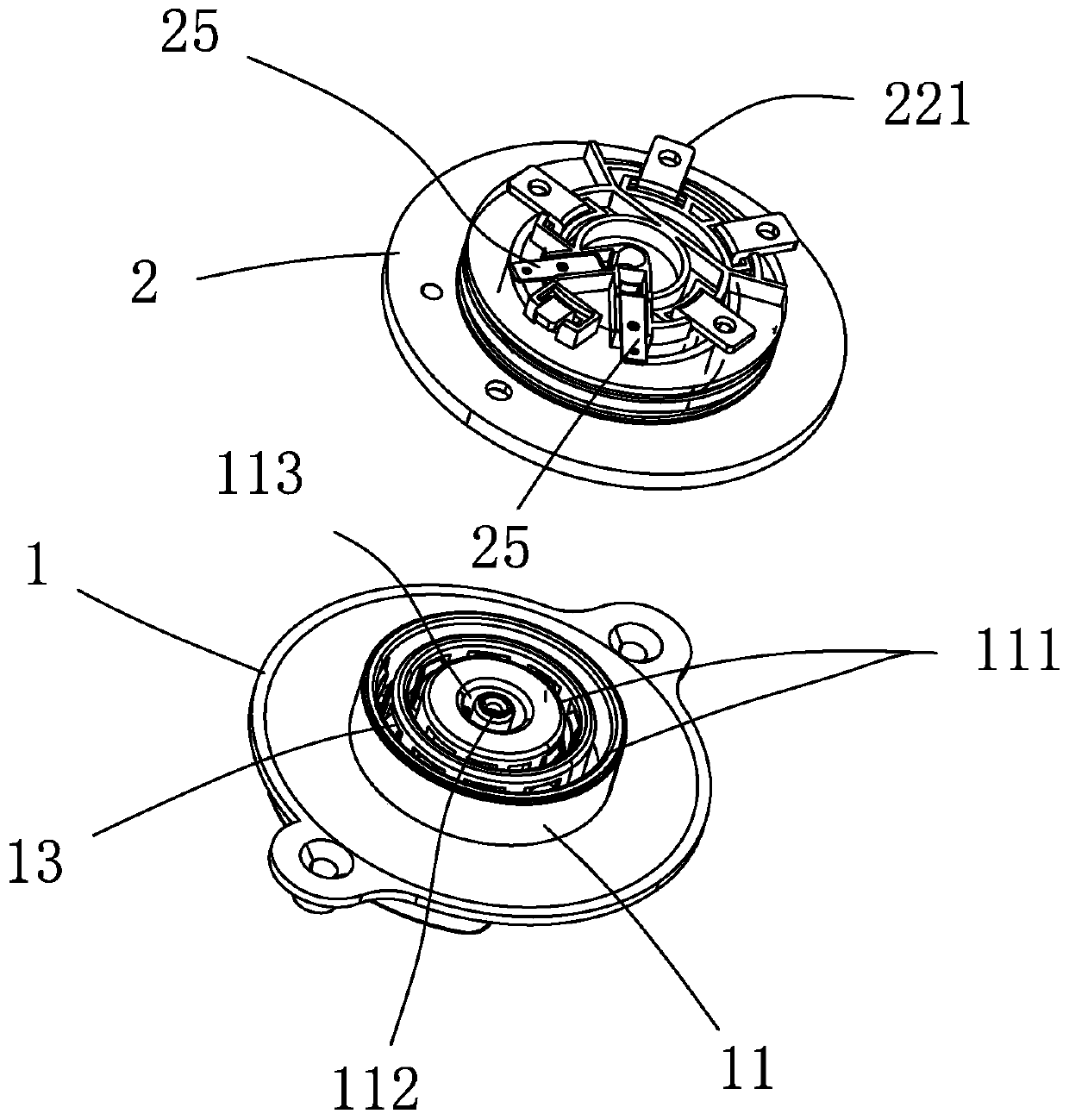

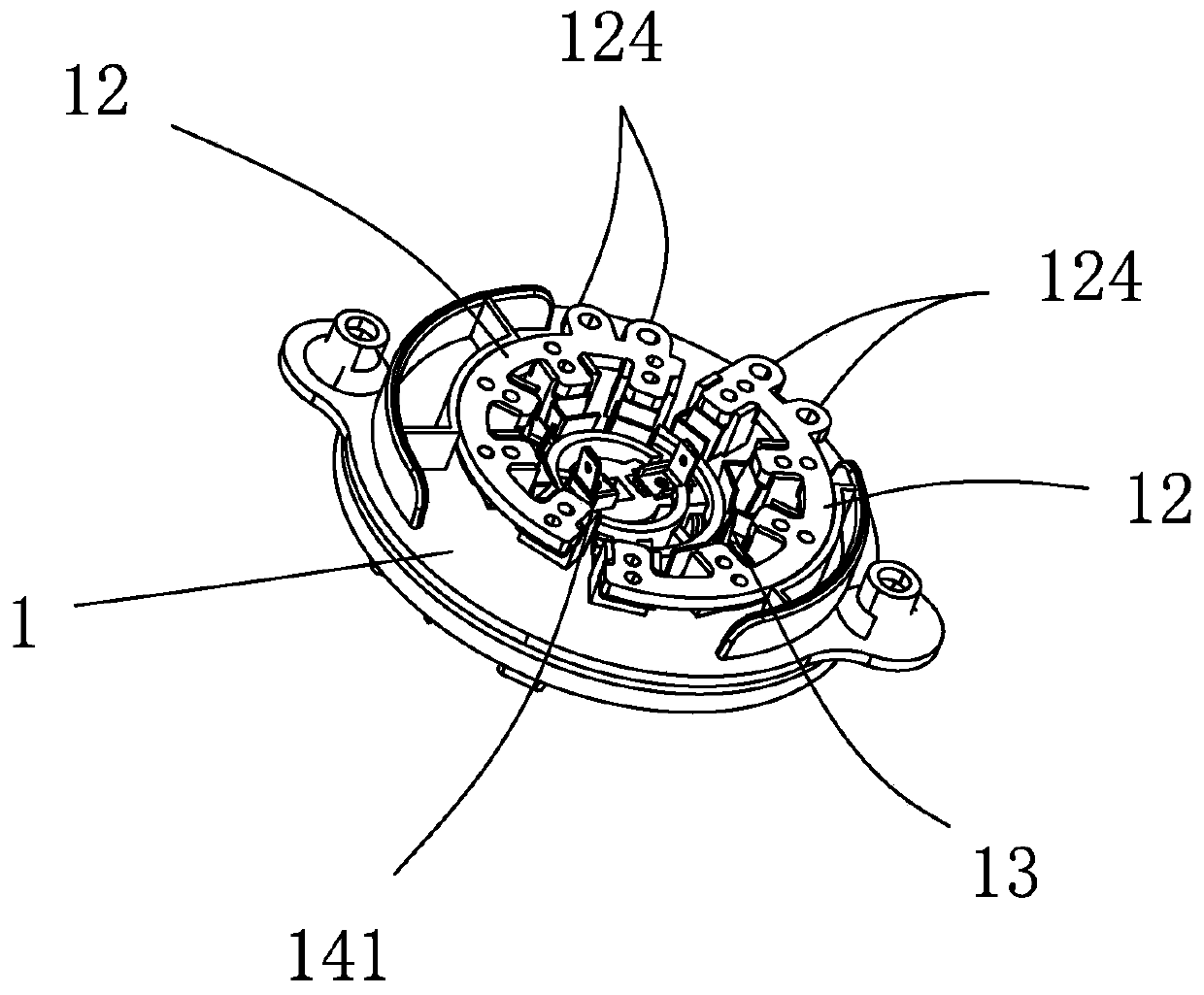

[0040] The embodiment of the large current coupler used in the battery car of the present invention is for example Figure 1-15 As shown: it includes a first coupling piece 1 and a second coupling piece 2 that are mated and plugged in. The first coupling piece 1 is provided with a relatively protruding plug-in part 11 on one end surface of the plug-in part 11. Two first annular slots 111 are concentrically arranged corresponding to the positive and negative poles of the circuit, and the other end surface of the first coupling member 1 is provided with two conductive sheets 12 corresponding to the first annular slots 111. Conductive strips 12 are provided corresponding to two first annular slots 111 respectively, and the two conductive strips 12 are respectively used to connect with the positive and negative poles during current transmission, and each conductive strip 12 is connected with multiple The first electrical contact strips 13 in an annular slot 111, these first electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com