Shell structure, shell manufacturing method and mobile terminal

A technology of shell structure and manufacturing method, applied in the field of electronic equipment, can solve the problems of lack of ceramic texture, affect the aesthetics of products, easy to damage, etc., and achieve high mechanical strength, good appearance effect, and the effect of improving mechanical strength and aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In the final consumer goods industry, product appearance is an important factor for consumers to purchase products. Therefore, novel and differentiated visual appearance or decorative effects are particularly important for consumer products. Taking smart phones as an example, consumers usually pay attention to the aesthetics of the back cover of the mobile phone when purchasing a mobile phone. In recent years, the back cover of mobile phones with gradient colors has become a design trend, and more and more mobile phone manufacturers have launched various Gradient phone.

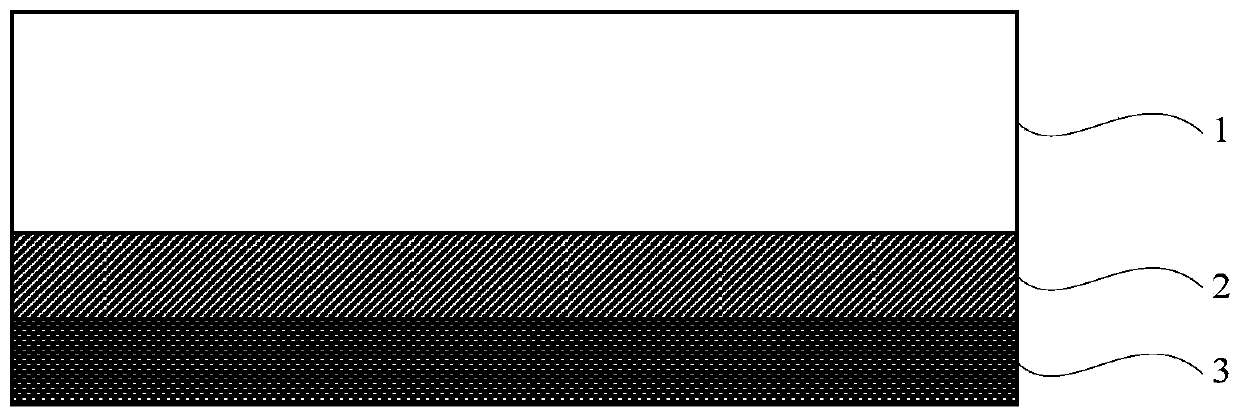

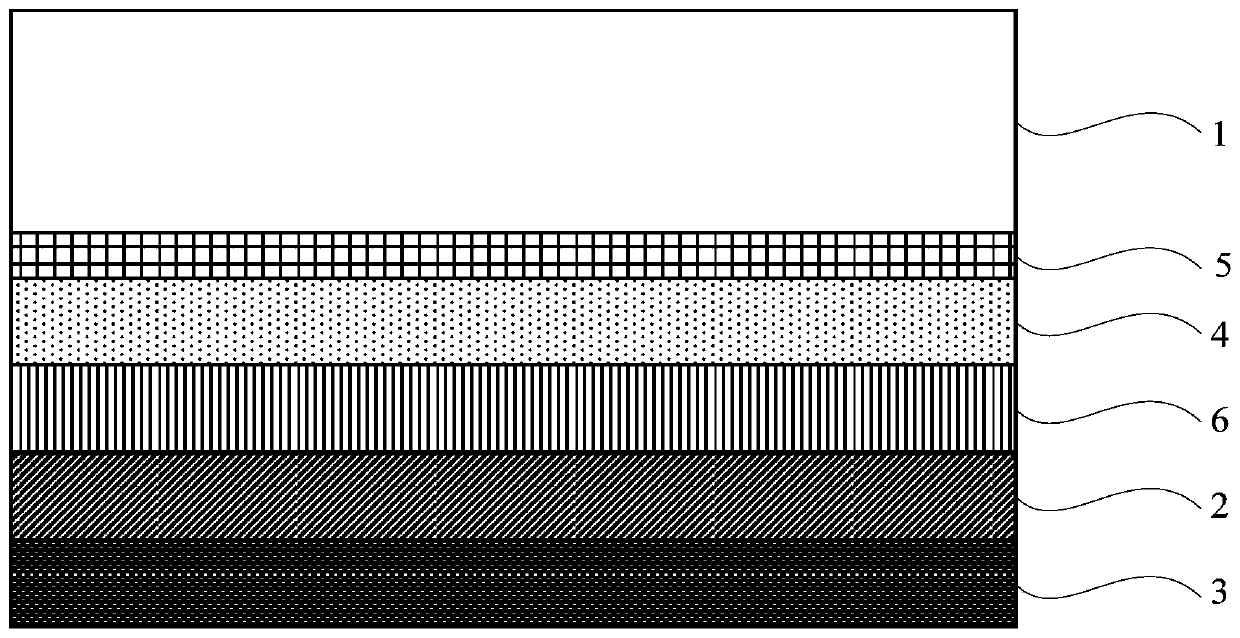

[0053] Most of the casings of mobile phones with gradient color appearances on the market are realized by coating on glass substrates, and there are mainly two technical solutions for them. figure 1 It is a structural schematic diagram of a casing in the prior art. Such as figure 1 As shown, a process scheme is to directly set the gradient coating layer 2 on the glass substrate 1, and then deposit th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com