Bubble removing device in small shrimp culture pond

A technology for breeding ponds and clearing bubbles, which is applied in fish farming, foam dispersion/prevention, animal husbandry, etc., can solve the problems of low bubble picking efficiency and long time consumption, so as to save time, improve efficiency, and use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

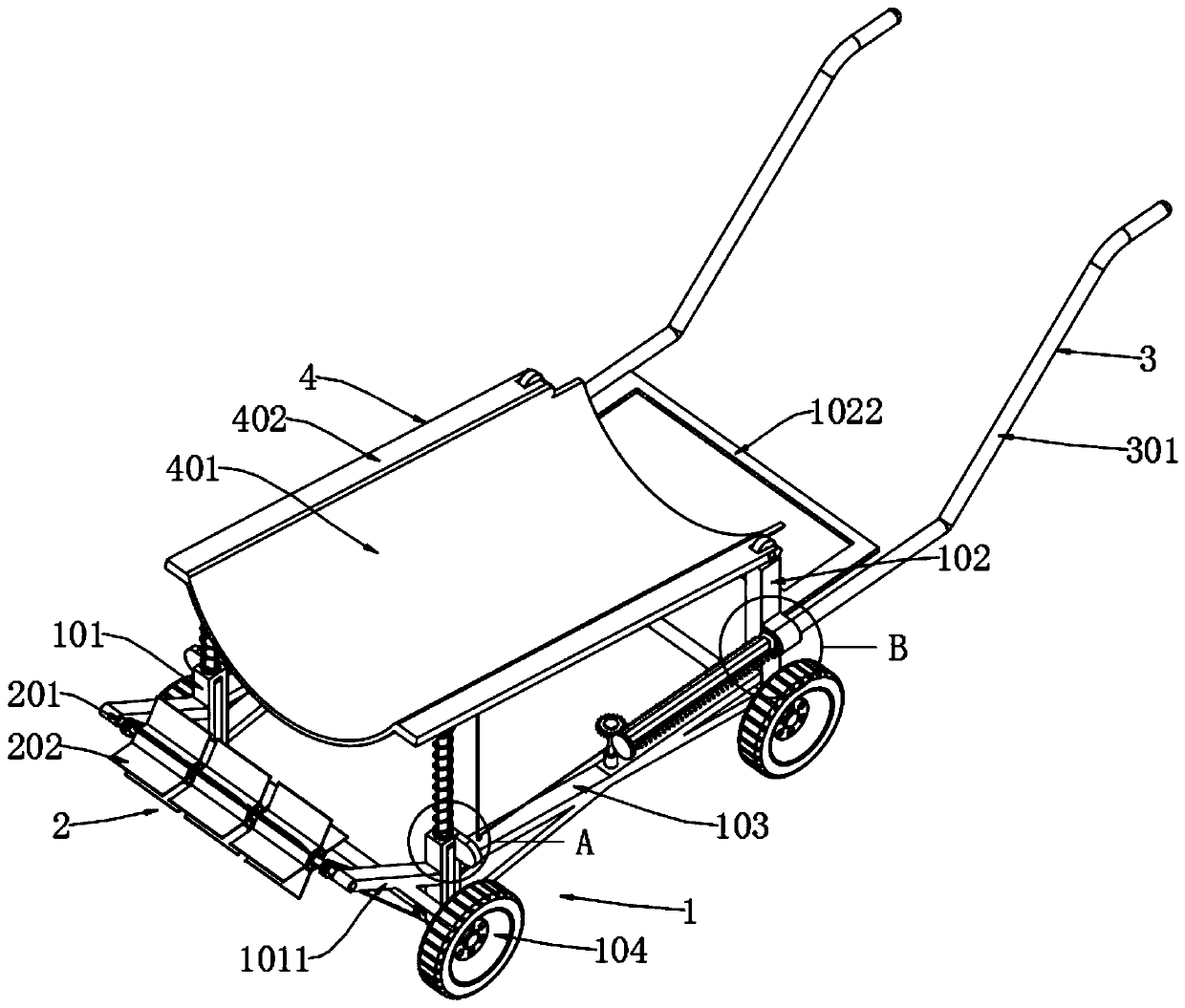

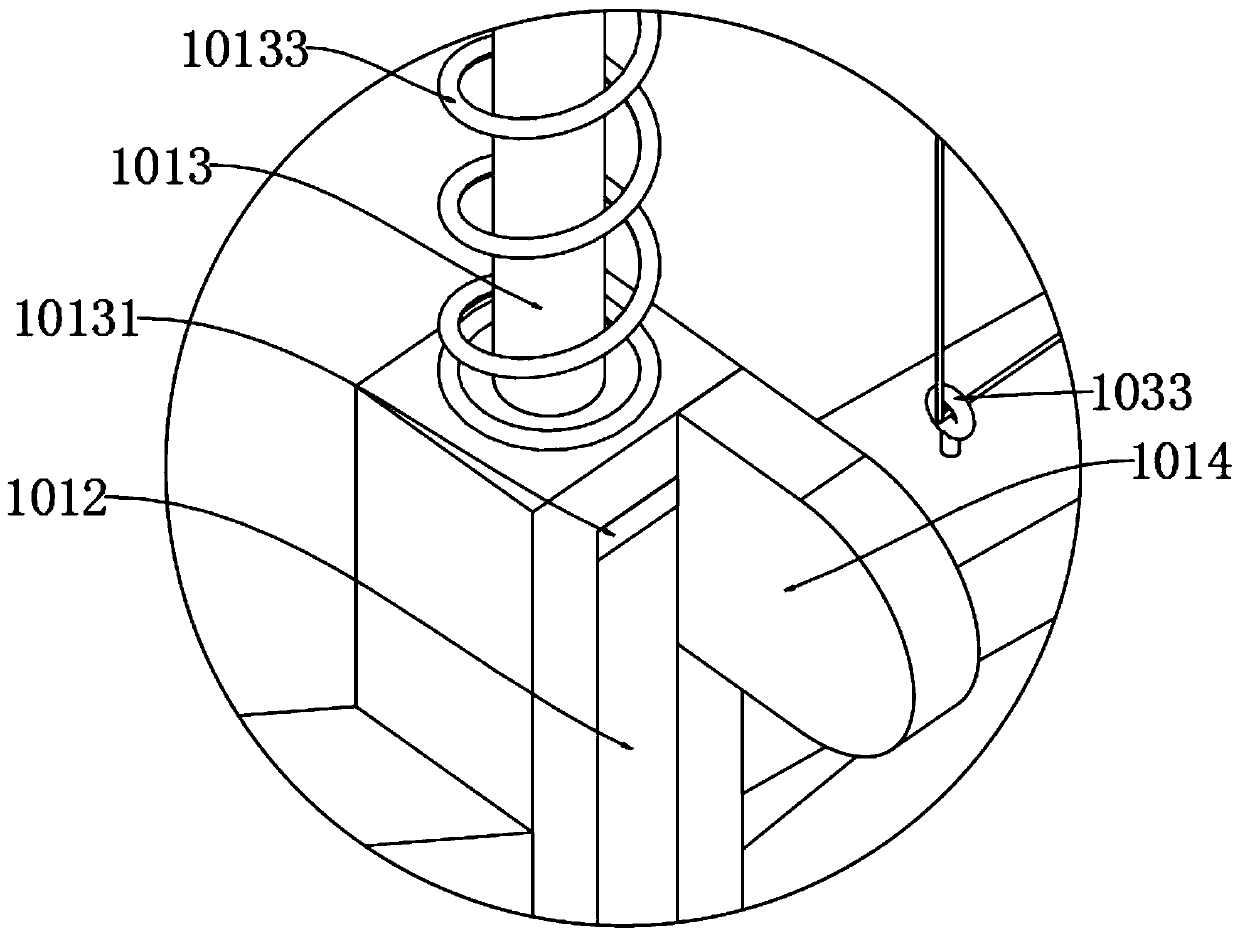

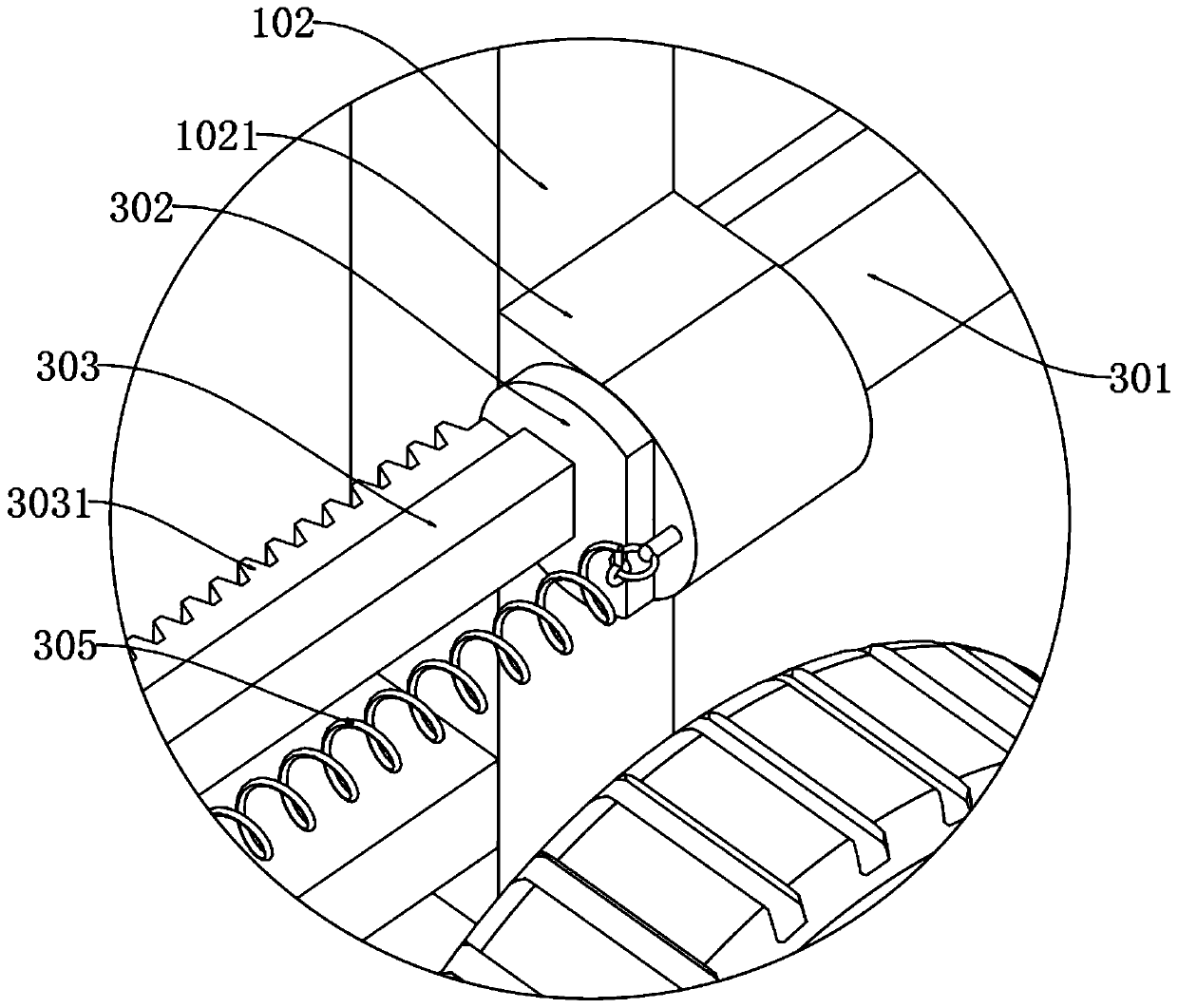

[0034] as attached figure 1 To attach Figure 8 Shown:

[0035]The invention provides a device for clearing bubbles in a shrimp breeding pond, which includes a foam diversion mechanism 2; the foam diversion mechanism 2 is connected to the front end of the traveling mechanism 1 and is connected to the traveling mechanism 1 through transmission, and the rear end of the traveling mechanism 1 is also slidingly installed with a pusher Mechanism 3, and the rear side top of traveling mechanism 1 is also rotatably connected with collecting mechanism 4, wherein, traveling mechanism 1 comprises front bracket 101, rear bracket 102, rib frame 103 and traveling wheel 104, and traveling wheel 104 is respectively connected by the rotation of traveling shaft At the bottom of the front bracket 101 and the rear bracket 102, a rib frame 103 is also connected between the front bracket 101 and the rear bracket 102, and the connection strength between the front bracket 101 and the rear bracket 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com