Circular shaft clamping tool

A technology for clamping tooling and round shafts, used in workpiece clamping devices, hand-held tools, manufacturing tools, etc., can solve problems such as easily damaged shaft surfaces, and achieve the effects of low manufacturing cost, easy processing and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

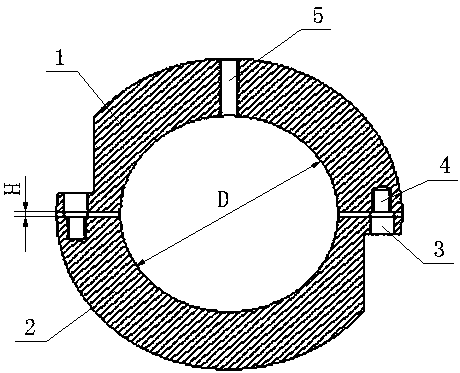

[0017] Such as figure 1 A circular shaft clamping tool shown includes a first clamping block 1 and a second clamping block 2 connected by bolts, the distance between the first clamping block 1 and the second clamping block 2 is H, and the first clamping block The distance H between the block 1 and the second clamping block 2 is 2 mm. On the inside of the first clamping block 1 and the second clamping block 2, arc-shaped clamping surfaces are arranged symmetrically. The two arc-shaped clamping surfaces form a clamping cavity with a circular cross section. The cross-sectional diameter of the clamping cavity is D The size is the required clamping shaft diameter d+0.5mm. A screw mounting hole 5 is provided on the outer side of the first clamping block 1 .

[0018] On both sides of the arc-shaped clamping surface on the first clamping block 1 and the second clamping block 2, there are light holes 3 and threaded holes 4 for mounting bolts respectively, and the light holes 3 of the...

Embodiment 2

[0021] The difference between this embodiment and embodiment 1 is that the distance H between the first clamping block 1 and the second clamping block 2 is 3 mm. All the other features are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com