High-speed reciprocating transverse cutting saw

A horizontal cutting, high-speed technology, used in circular saws, sawing components, sawing equipment, etc., can solve the problems of customer difficulties in maintenance, easy wear of copper bushings, and reduced sawing accuracy, so as to solve the problems and The effect of hidden danger, small installation space and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 High-speed reciprocating cross-cut saw

[0041] see Figure 1 to Figure 8 , the present invention provides a high-speed reciprocating cross-cut saw, including a feeding part 100 , a cutting part 200 and a discharging part 300 .

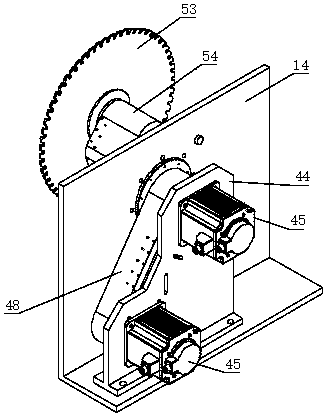

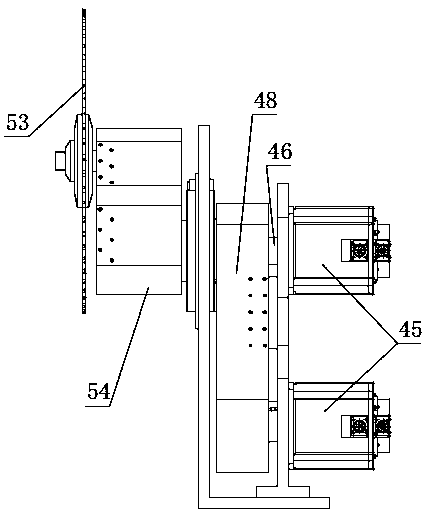

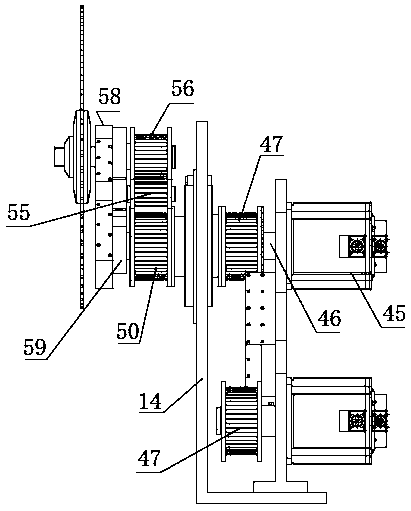

[0042] The cutting part 200 includes an adjusting pressing device, a feeding board and a cutting device arranged under the feeding board.

[0043] The cutting device includes a vertical plate 14, the vertical plate 14 is an L-shaped plate, the servo motor fixing plate 44 is fixedly installed on the vertical plate 14, and two cutting mechanism servo motors are fixedly installed on the servo motor fixing plate 44. Motor 45, each cutting mechanism servo motor 45 is connected with the first synchronous pulley 47 that is arranged on the other side of servo motor fixed plate 44 by the first swing arm shaft 46, two first synchronous pulleys 47 are connected by belt transmission, The exteriors of the two first synchronous pulleys 47 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com