Low-floor tramcar floating car end beam and lower part hinged mounting base structure

A technology for trams and mounting seats, which is applied to railway car body parts, railway car bodies, transportation and packaging, etc., and can solve cracks at the end of the car body and hinged seats, large force on the mounting seat and end beam, and force on the hinged mechanism Large and other problems, to achieve the effect of reducing self-weight, reasonable force, and consistent transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

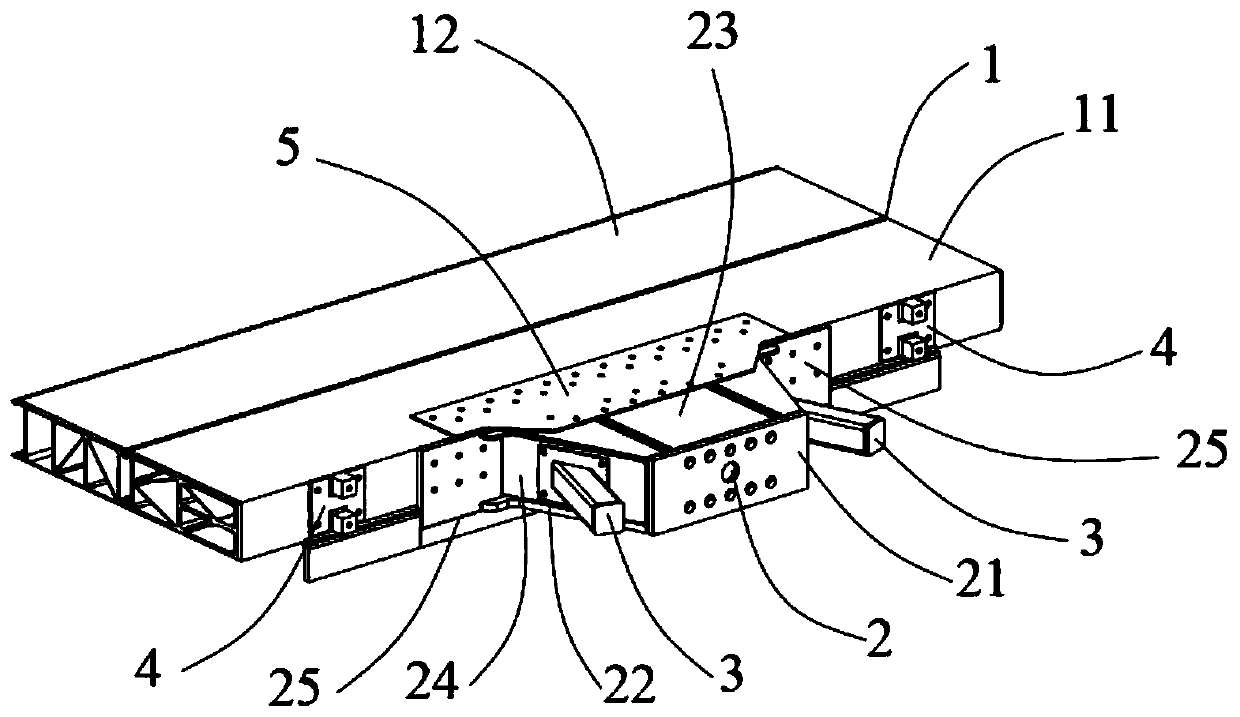

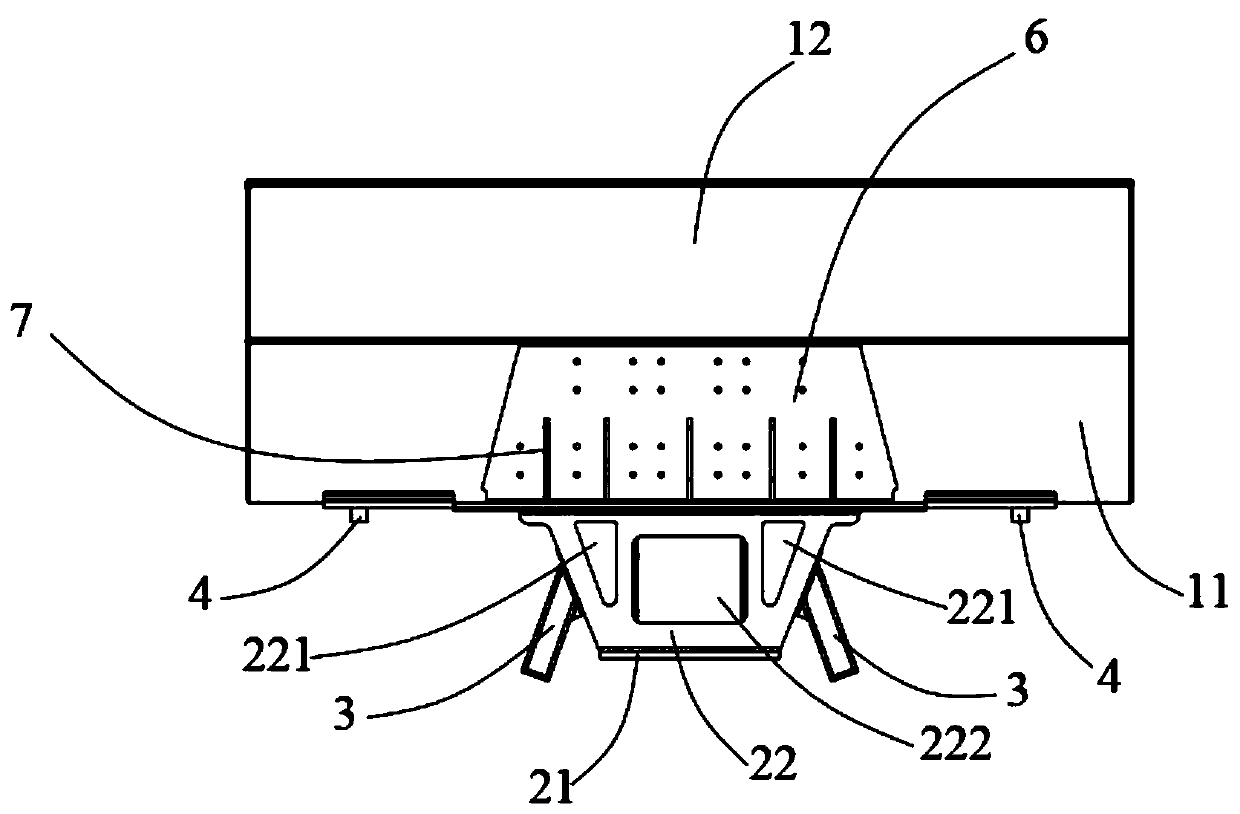

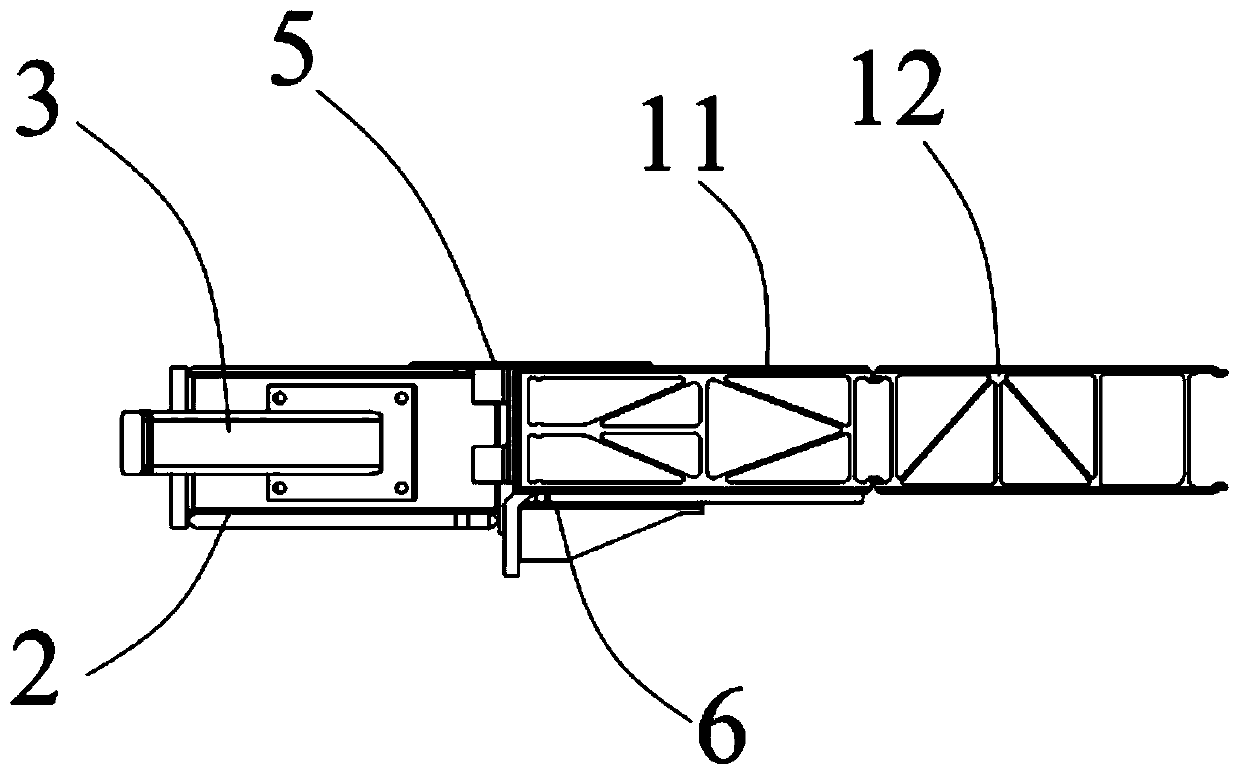

[0024] figure 1 , figure 2 and image 3 In order to solve the above-mentioned technical problems, the present invention is achieved through the following technical solutions: a low-floor tram floating car end beam and lower hinged mounting seat structure, including end beam 1 and the center of the rear end of end beam 1 The hinged mounting base 2, the end beam 1 is respectively provided with a workshop damping mounting base 4 on the left and right sides of the hinged mounting base 2, and the two workshop damping mounting bases 4 are left and right symmetrical with the hinged mounting base 2 as the center , the hinged mounting base 2 is provided with two rotational stoppers 3 that are left and right symmetrical about its center; the end beam 1 is composed of a main profile 11 with a rectangular structure and a secondary profile 12 with a rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com