Four-joint wagon and connecting method thereof

A railway freight car and connection method technology, which is applied to railway car body parts, freight cars, railway couplings, etc., can solve the problems of difficulty in adapting to transportation capacity requirements, vehicle load restrictions, and reduction of the number of axles of the whole vehicle, achieving light weight, Low maintenance cost and the effect of reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

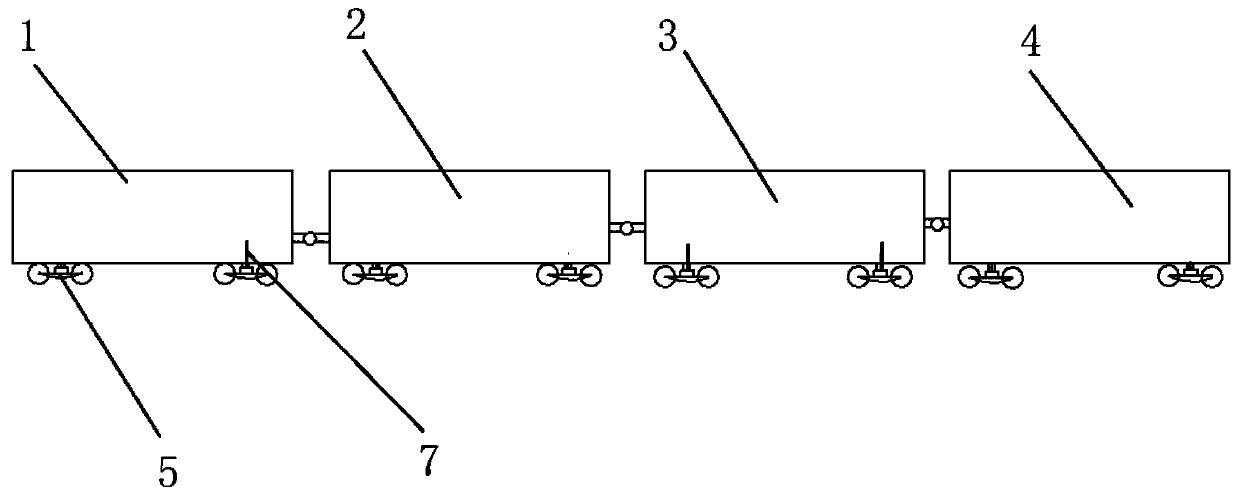

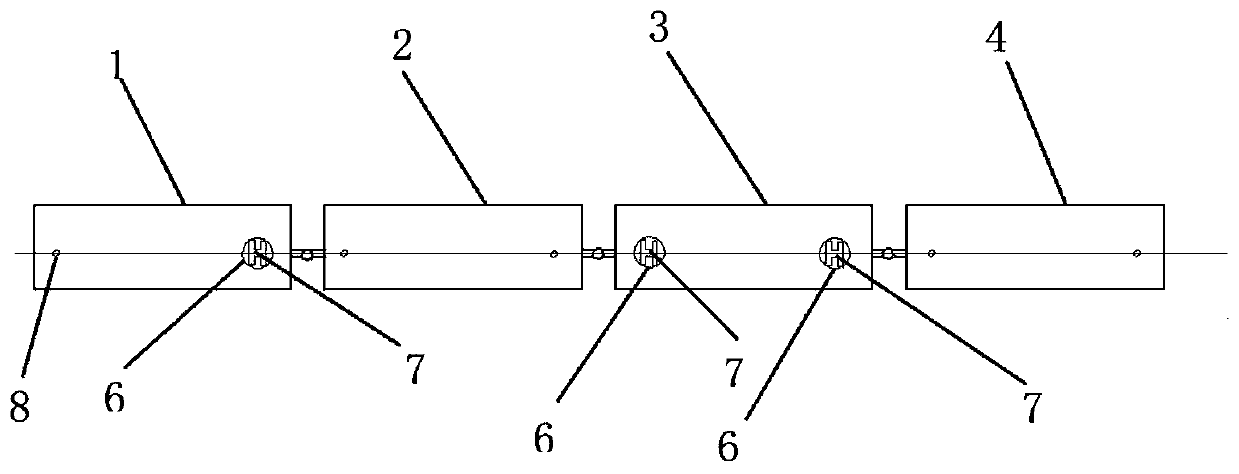

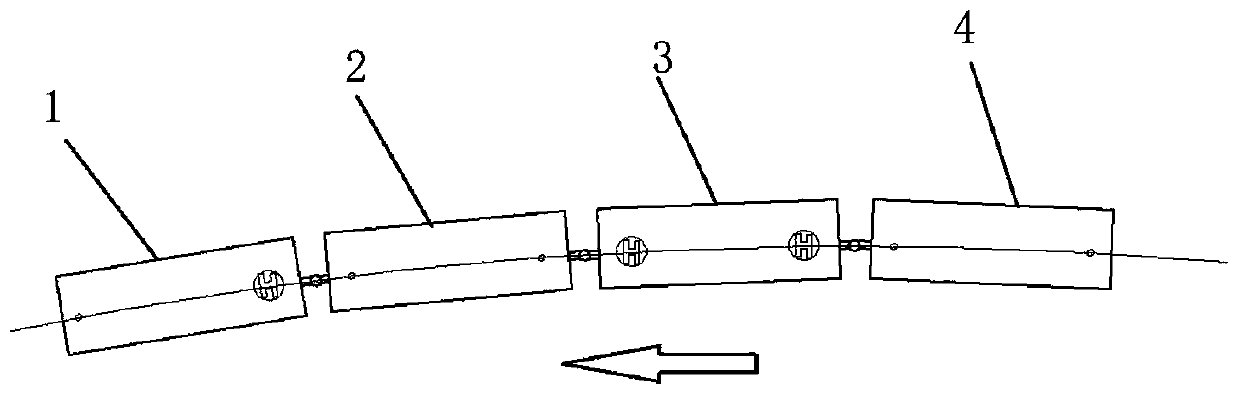

[0022] A four-section railway freight car, such as figure 1 with figure 2 Shown, a kind of four section railway wagons, comprise the wagon one 1, wagon two 2, wagon three 3, wagon four 4 that are serially connected in sequence, wagon one 1, wagon two 2, wagon three 3, wagon four 4 are all made of two The two-axle bogie is supported by 5 hubs, that is, the lower center disc of the two two-axle bogies cooperates with the upper center disc of the truck, and the car bodies of truck one 1, truck two 2, truck three 3, and truck four 4 can only rotate, not horizontally , longitudinal movement, truck two 2, truck four 4 are the main vehicle, truck one 1, truck three 3 are auxiliary vehicles, and the two-axis bogie adjacent to the main vehicle end of the auxiliary vehicle can move laterally relative to the car body, truck one 1, truck two 2 1, frei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com