EMU Elastic Clay Buffer Device

A technology of elastic cement and buffer device, which is used in buffers, transportation and packaging, railway car body parts, etc., can solve the problems of low sealing reliability, high initial resistance and poor low temperature recovery, and achieve reliable sealing and stable performance. , the effect of high absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

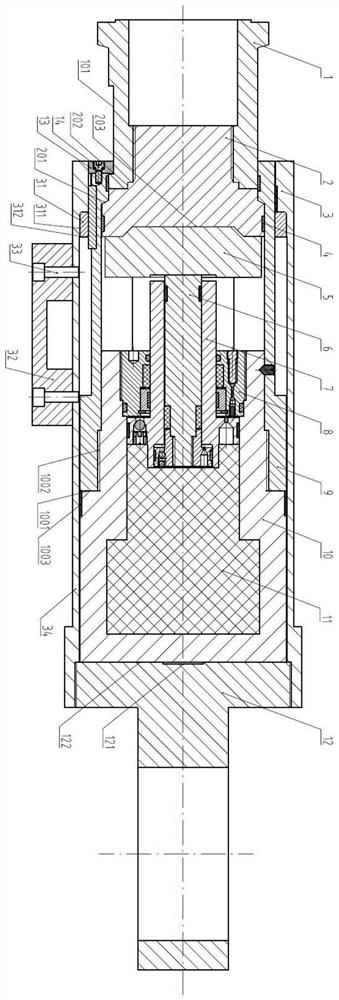

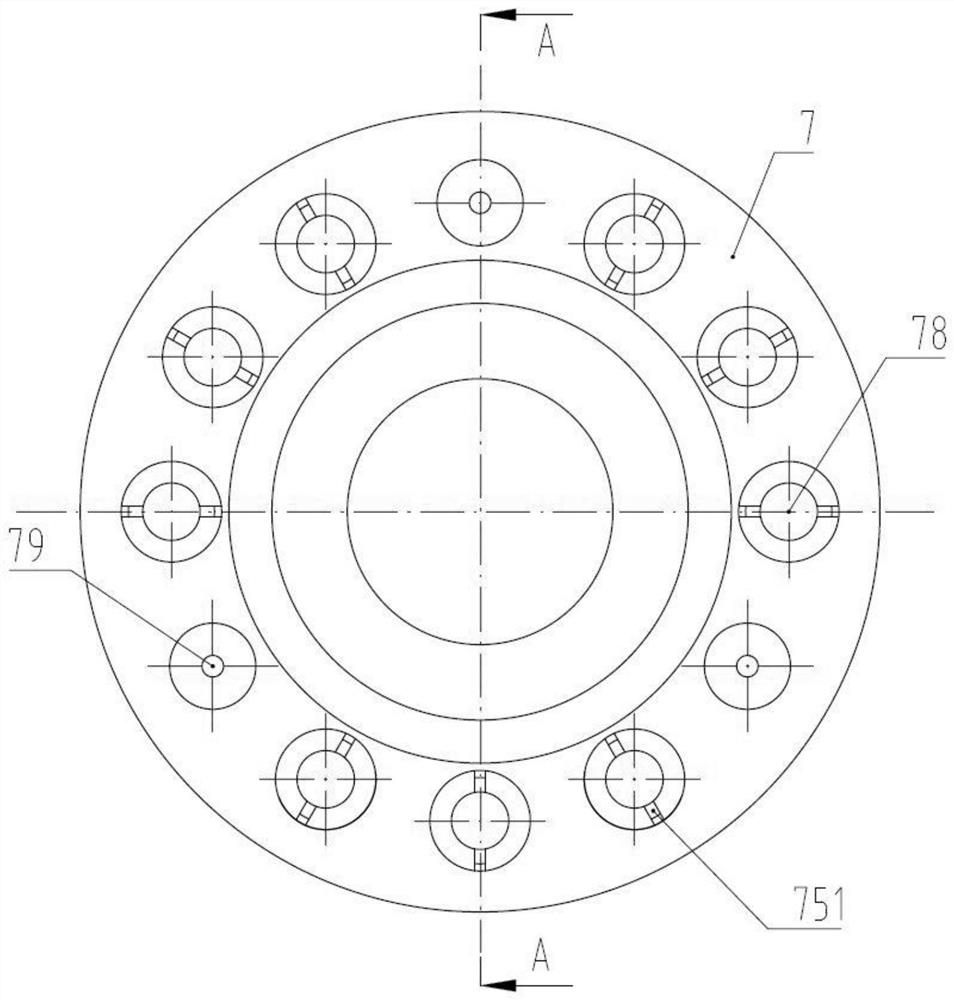

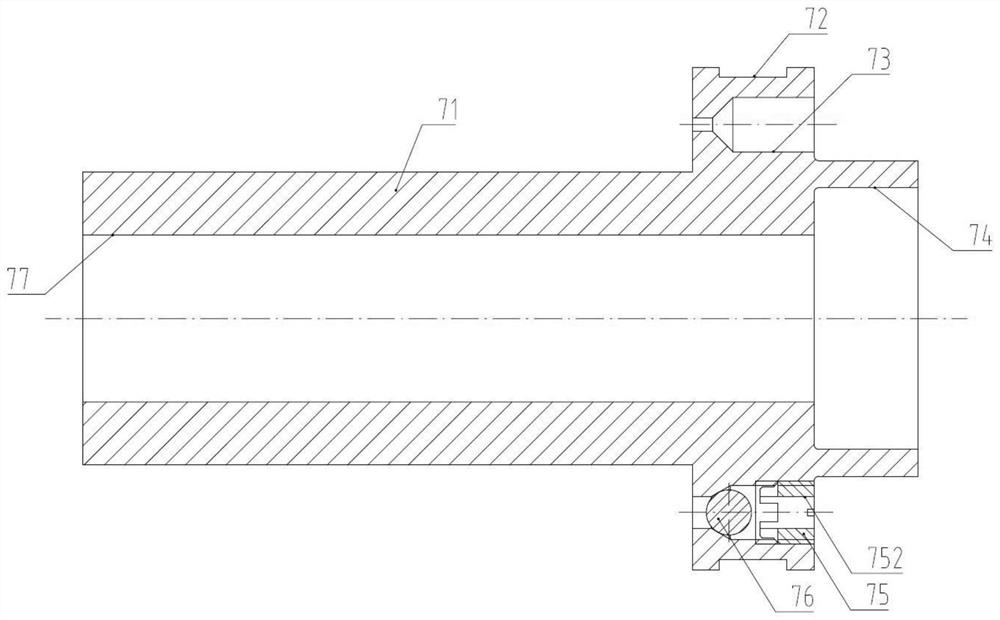

[0029] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0030] refer to figure 1 As shown, the patented product of the present invention includes a slider 1, a slider seat 2, a top plate 5, a puller assembly 9, an inner piston rod assembly 6, an outer piston rod assembly 7, a cylinder head assembly 8, and a cylinder body coaxially installed together. 10. The anti-rotation block 13, the outer cylinder assembly 3, the rear pull ring 12 threadedly connected with the outer cylinder 34, and the elastic cement material 11 that is pressure-packed inside the cylinder body 10. The outer cylinder assembly 3 includes an outer cylinder 34 , a positioning ring 31 , a positioning block 32 , and mounting screws 33 . The positioning block 32 adopts a hollow structure, and is connected with the outer cylinder 34 by two screws 33, and the screw threads are coated with thread fastening glue to prevent loosening.

[0031] re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com