Shower-type rope-shaped water washing unit

A water washing unit and shower type technology, which is applied in textiles and papermaking, spray/jet textile material treatment, textile material treatment, etc., can solve the problems of reducing the amount of fabric in the tank, fabric wrinkles, and low washing efficiency, achieving reduction The effect of turning over and knotting, reducing the requirement of liquid level height, and improving the washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

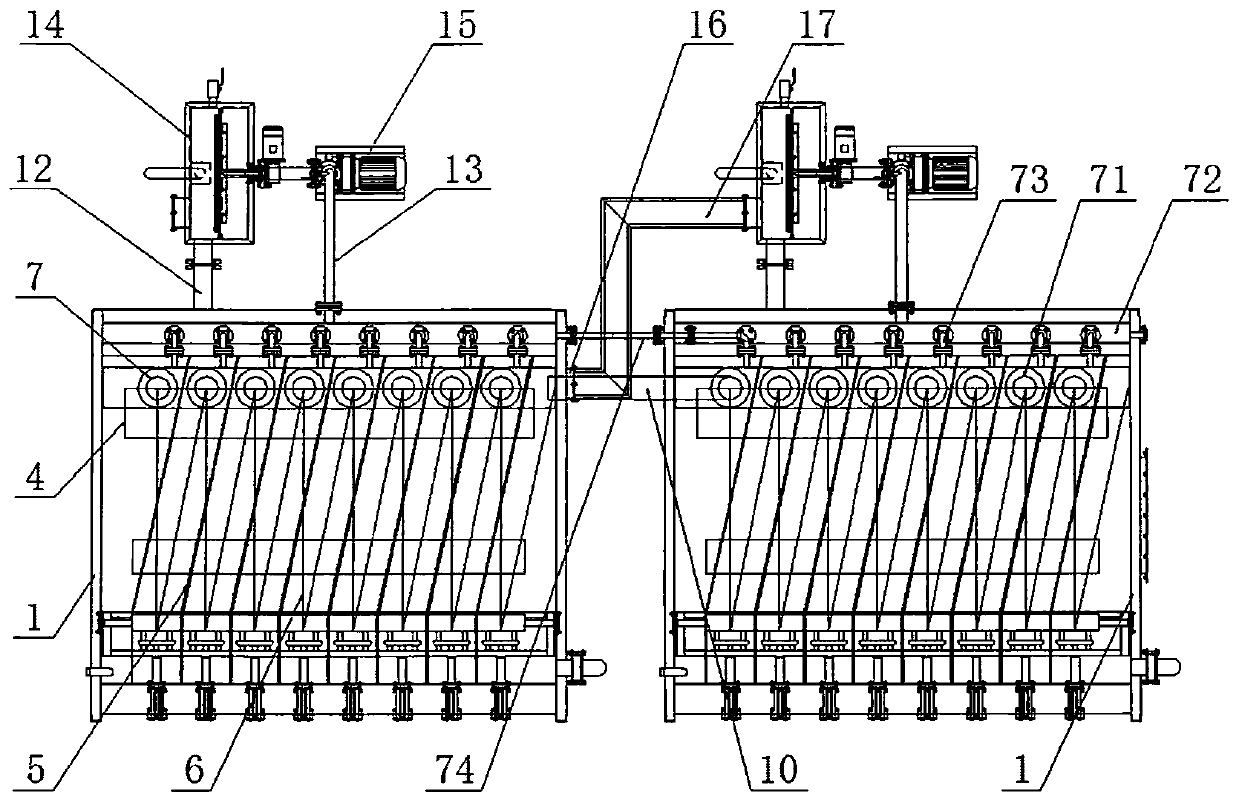

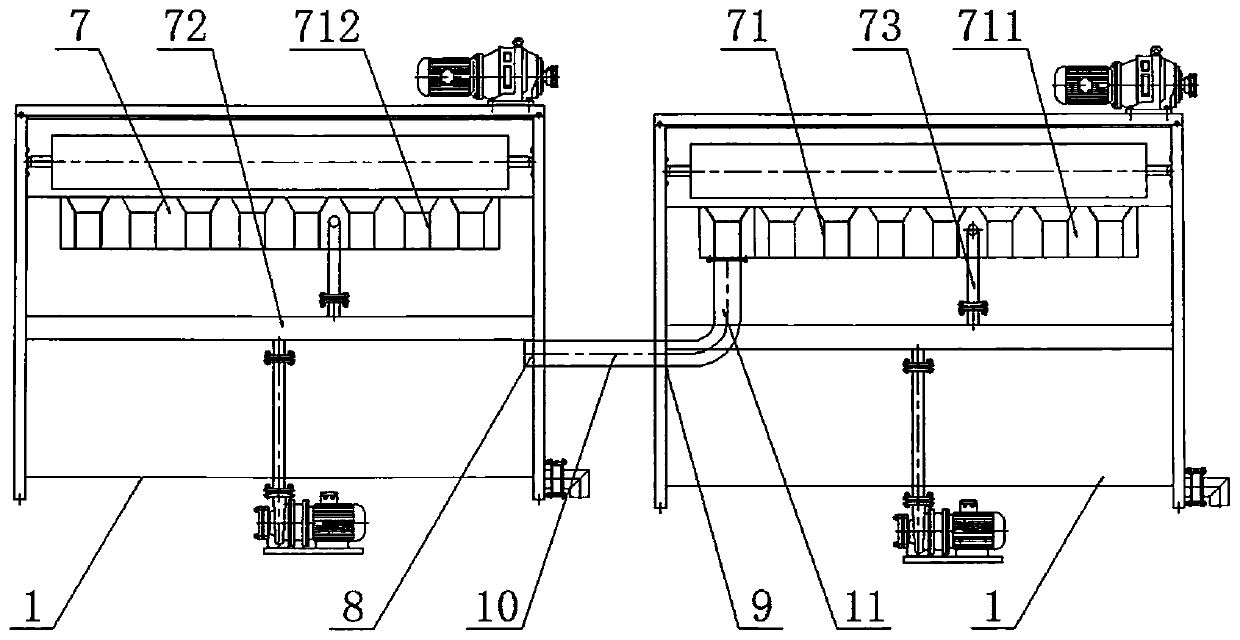

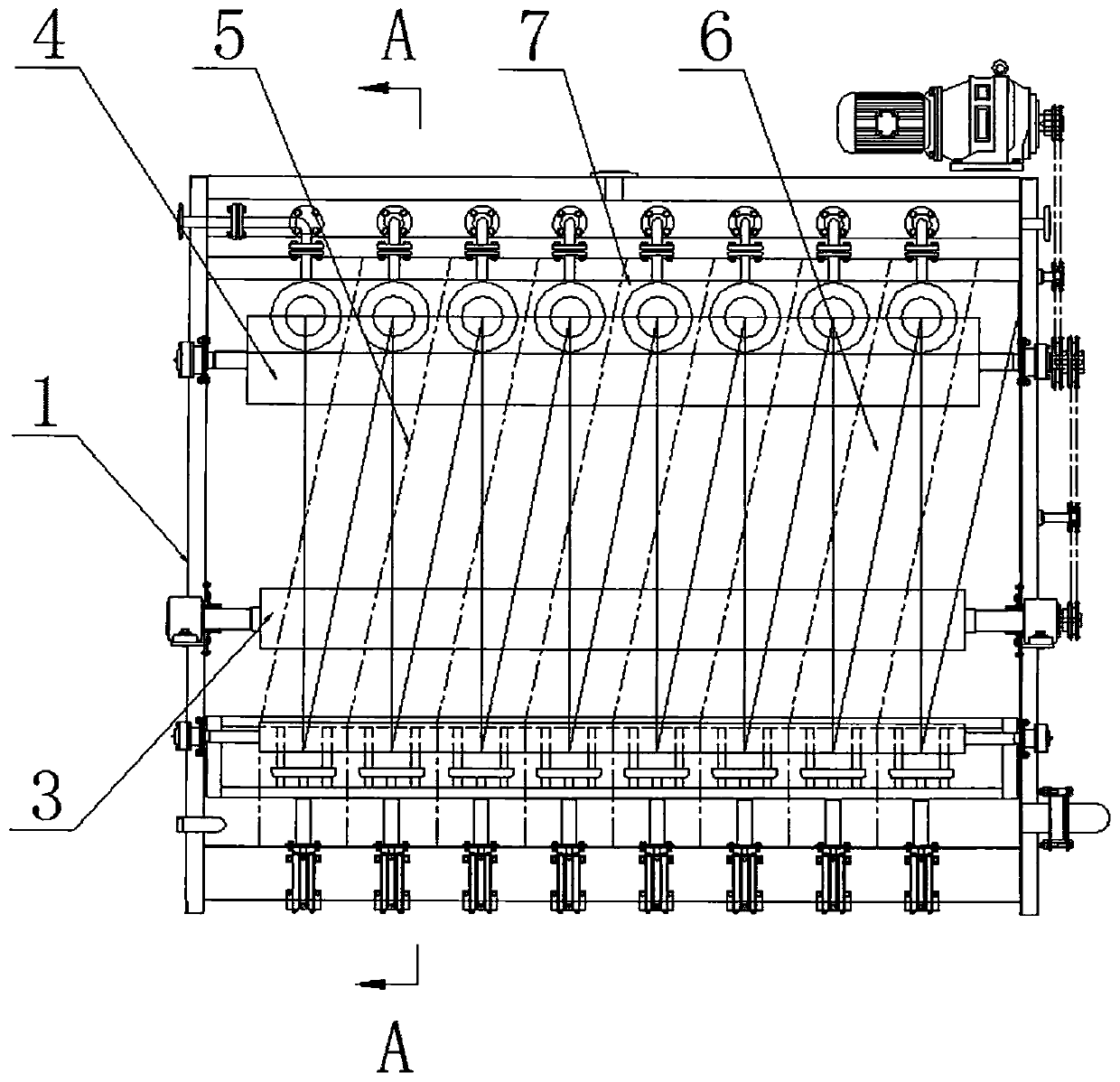

[0062] see Figure 1 to Figure 9 , a shower type rope washing machine related to the present invention, it includes a plurality of washing units arranged front and back, the washing units include a unit box 1, a water tank 2 is arranged at the bottom of the unit box 1, and a water tank 2 is arranged above the water tank 2 A roller group 3 and a doffing roller 4 are provided, and the doffing roller 4 is located on one side of the roller group 3, and a plurality of partitions 5 are arranged in the water tank 2, and the water tank 2 is divided into multiple partitions by the plurality of partitions 5. a unit cell 6, a shower assembly 7 is arranged below the doffing roller 4;

[0063] The shower assembly 7 includes a plurality of shower units 71 at the front and rear, and each shower unit 71 corresponds to a cell 6;

[0064] The front and rear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com