Commercial vehicle inerter with adjustable inertance being self-adaptive to working conditions

A technology of inertia coefficient and inerter, which is applied in the field of commercial vehicles with variable inertia coefficient under adaptive working conditions, can solve the problems that the inertia coefficient cannot be continuously variable, there is a control time lag, and it cannot be adjusted. Achieve the effect of reducing the no-load bias frequency, not increasing the stress of the suspension system, and working reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

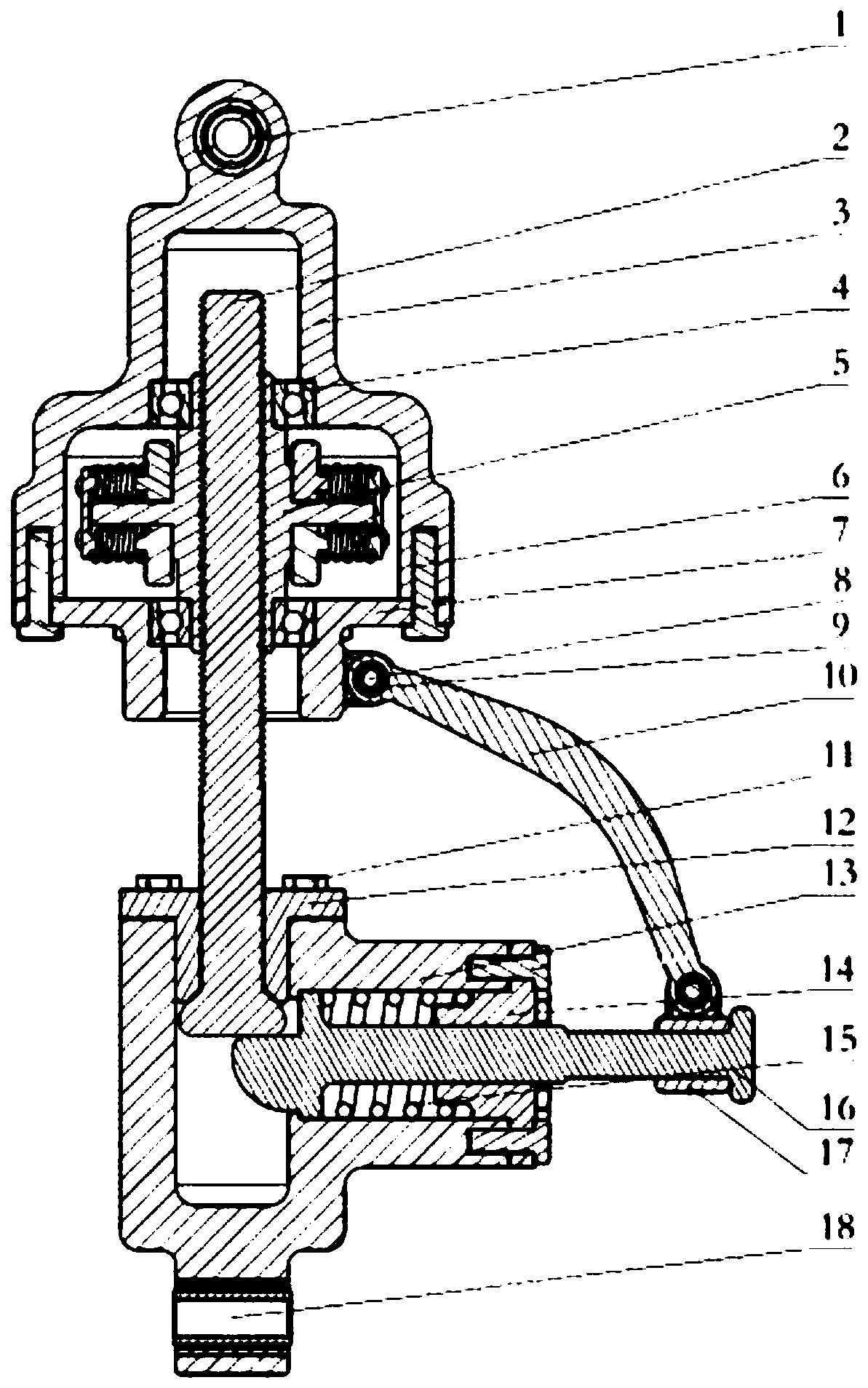

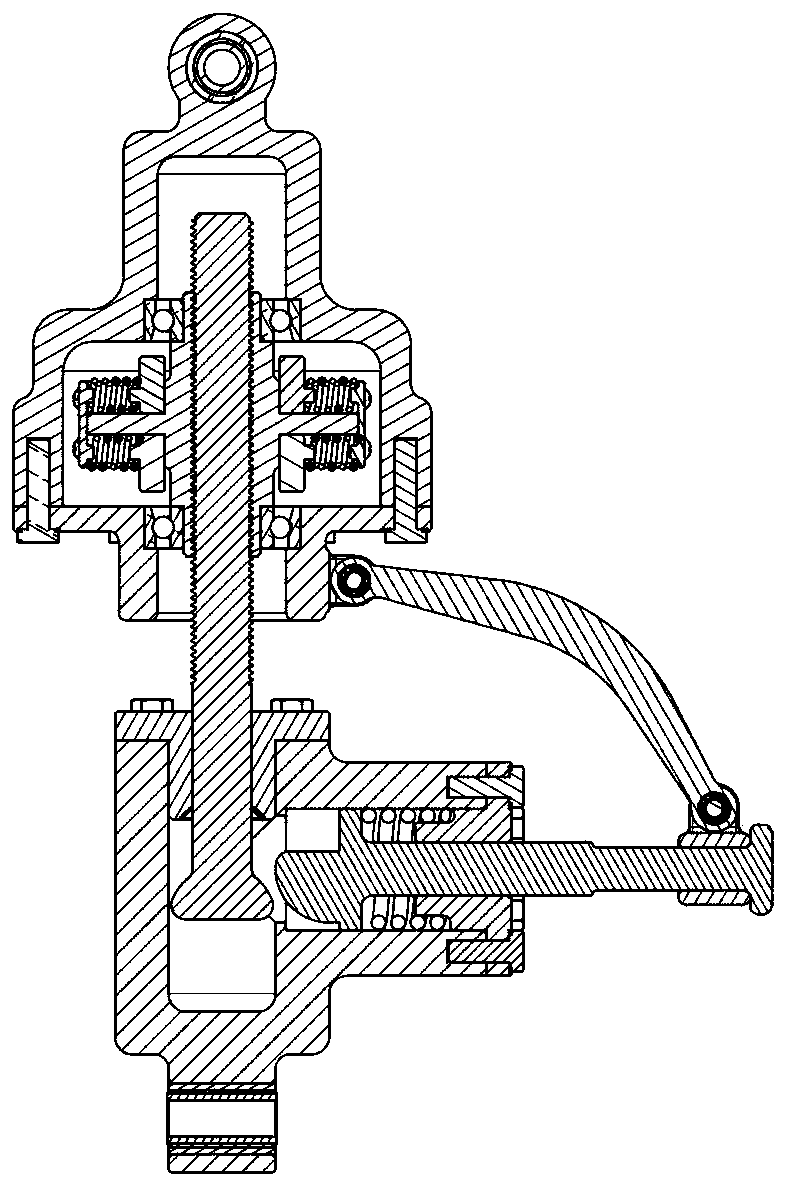

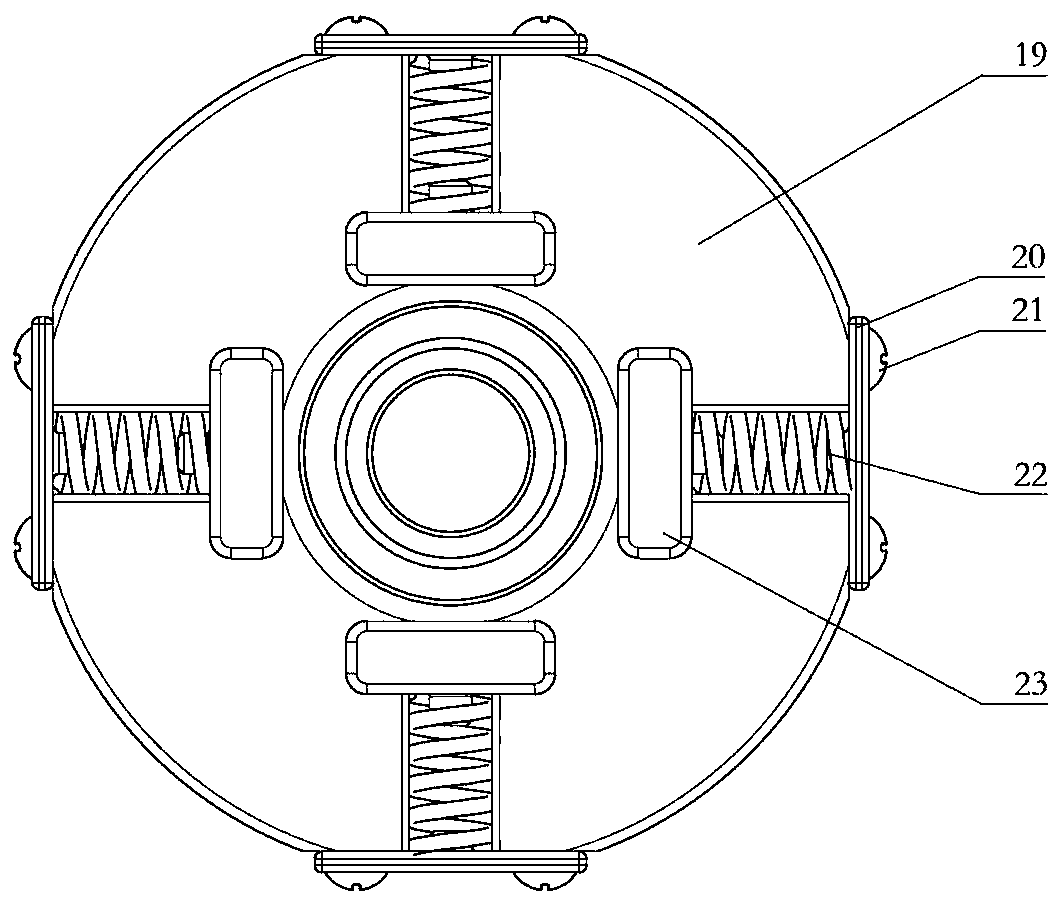

[0026] Such as figure 1 As shown, the patented design of the present invention is an inerter with a variable inertia coefficient for adaptive working conditions of commercial vehicles, including the main body of the inerter, the metamorphic mechanism and the connecting rod slider mechanism. The main body of the inerter is connected with the mobile pair formed by the rounded square section polished rod at the lower part of the ball screw 2 and the lower limit flange 12, and the main body of the inerter is connected with the upper part of the ball screw 2 by threads; The lower end of the block mechanism links to each other with the moving pair formed by the slider 17 through the circular cross-section polished rod at the rear end of the limit rod 16; the upper end of the connecting rod slider mechanism is connected with the main body of the conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com