Pipe guaranteeing device for down-hole paste filling and control method

A technology of paste filling and control method, which is applied in the direction of filling, valve device, safety device, etc., to achieve the effect of realizing visualization, ensuring pipeline safety and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

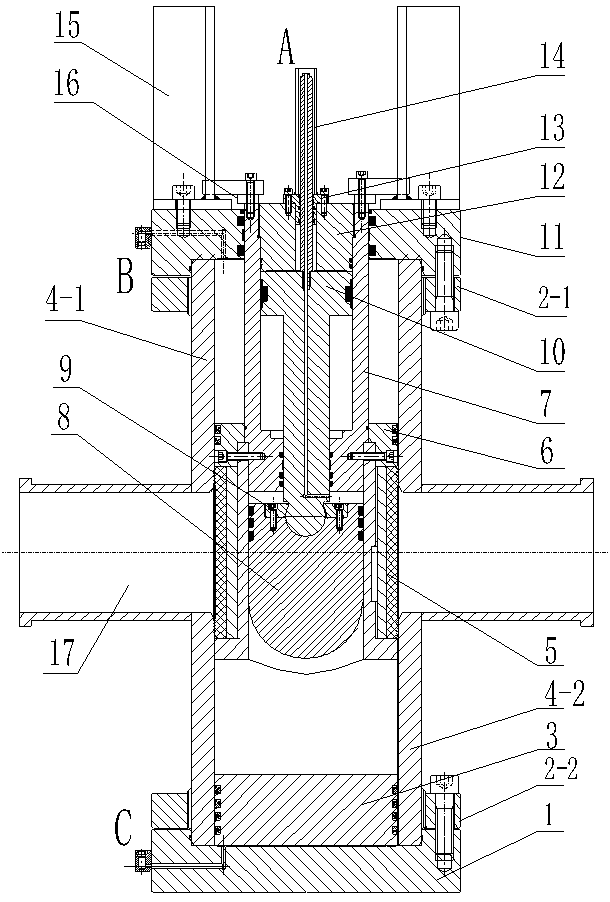

[0048] Embodiment 1: as figure 1 , Schematic diagram of the structure when the paste filling pipeline protection device is closed. When the hydraulic oil is passed through the oil inlet and outlet of B, the shaft core reaches the bottom of the valve body, and the adjustment head is inside the shaft core, which protects the seal of the adjustment head, and the main pipeline is completely cut off.

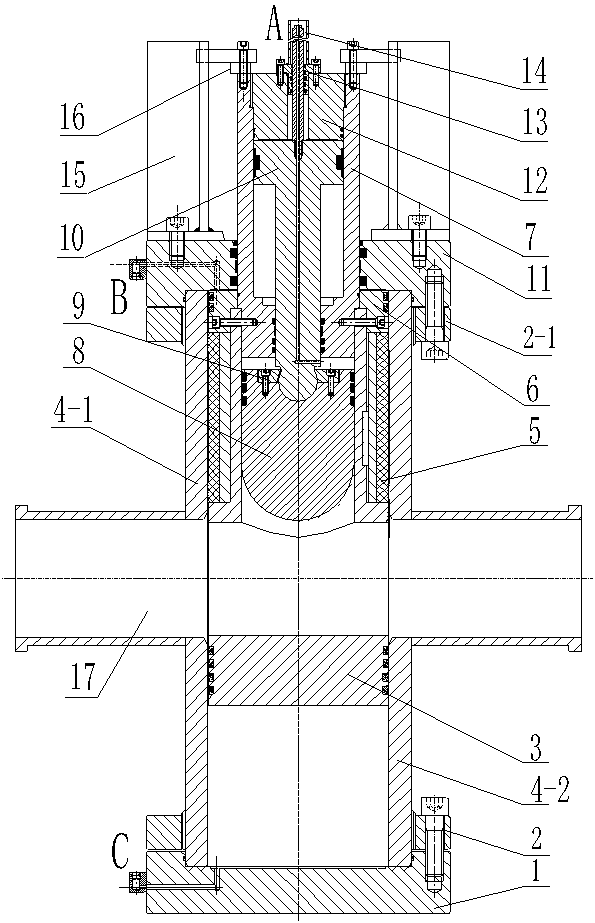

[0049] figure 2 It shows the schematic diagram of the main pipeline of the paste filling pipeline guarantee device when the main pipeline is fully opened. When the hydraulic oil is passed through the oil outlet of C, the shaft core is pushed to the top. The through hole of the shaft core coincides with the main pipeline, and the pipeline is fully opened. The flow is at its maximum.

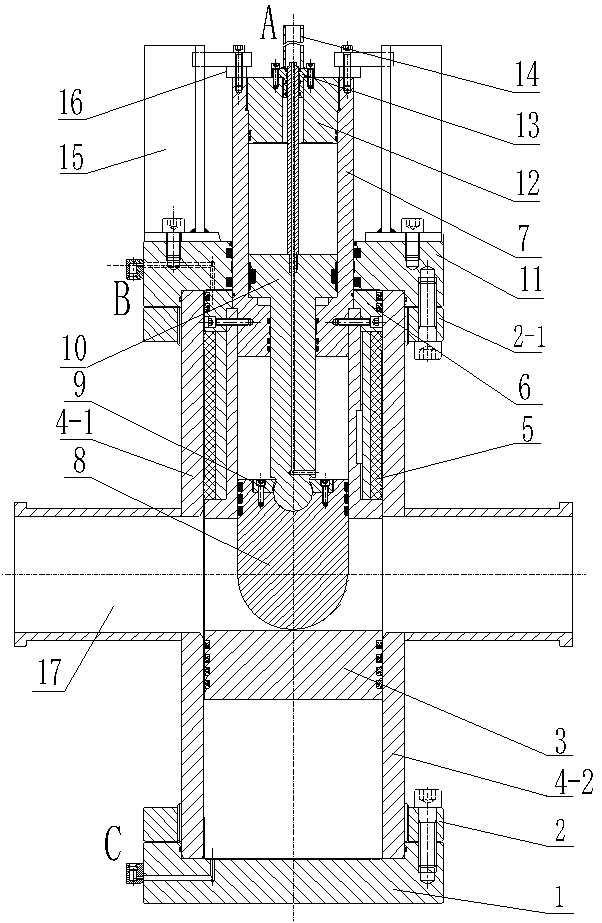

[0050] image 3 It shows the schematic diagram of regulating the flow rate of the paste filling pipeline guarantee device. When the oil inlet and outlet of A and the oil inlet and outlet of B are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com