A multi-screen support device in a high-temperature adiabatic calorimeter

A technology of supporting device and calorimeter, applied in the field of mechanical supporting device, can solve the problems of reduced experiment repeatability, time-consuming disassembly and assembly, low coaxiality of adiabatic screen and protective screen, etc., so as to improve the repeatability and reliability of experiments. Easy disassembly and assembly, high assembly coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

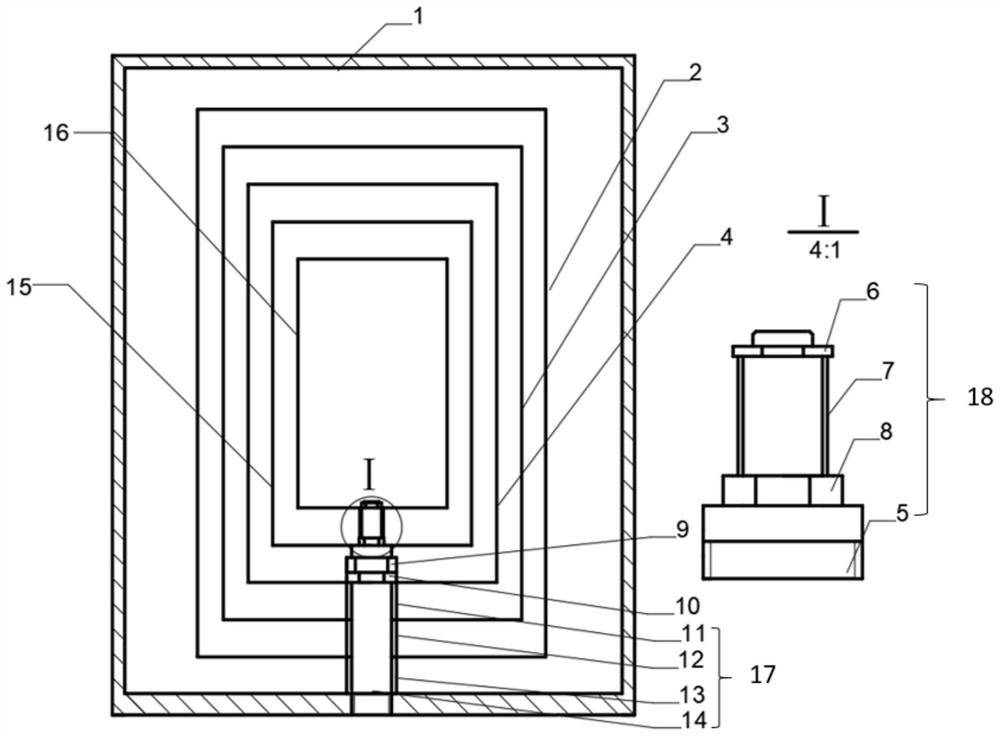

[0015] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

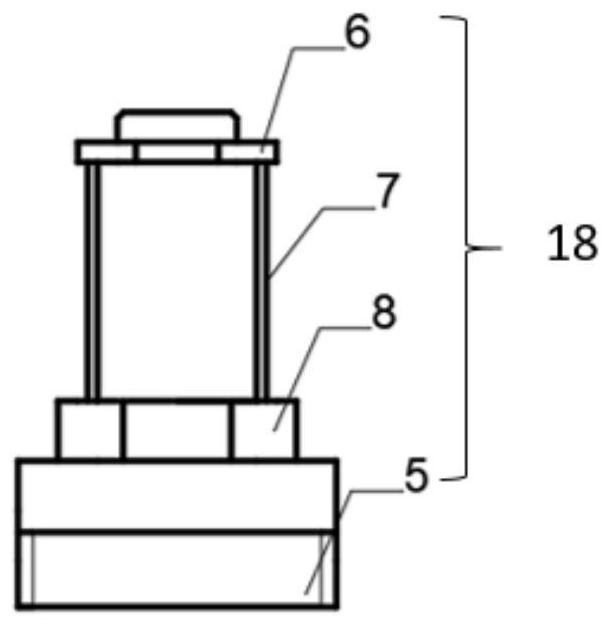

[0016] Both ends of the support pipe 14 are threaded, one end of the support pipe 14 is a sealing thread connected with the vacuum tank 1 , and the other end is threaded with the connecting piece 9 and the third nut 10 with ordinary fine thread. After the stainless steel tube 14 is connected with the vacuum tank 1 , the third sleeve 13 penetrates into the support tube 14 and then the lower cover and cylinder body of the outer protective screen 2 penetrate into the support tube 14 . At this time, the third sleeve 13 supports the outer protective screen 2 , limiting the movement and rotation of the outer protective screen 2 along the X and Y axes and the movement along the Z axis, so as to realize the complete positioning of the outer protective screen 2 . The second sleeve 12 penetrates into the support pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com