Angle adjusting mechanism

An angle adjustment and screw adjustment technology, applied in installation, optics, instruments, etc., can solve the problems of high operator requirements, practice, and cumbersome adjustment methods, and achieve the effect of reducing the difficulty of operation, simplifying the adjustment method, and reducing the coordination of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

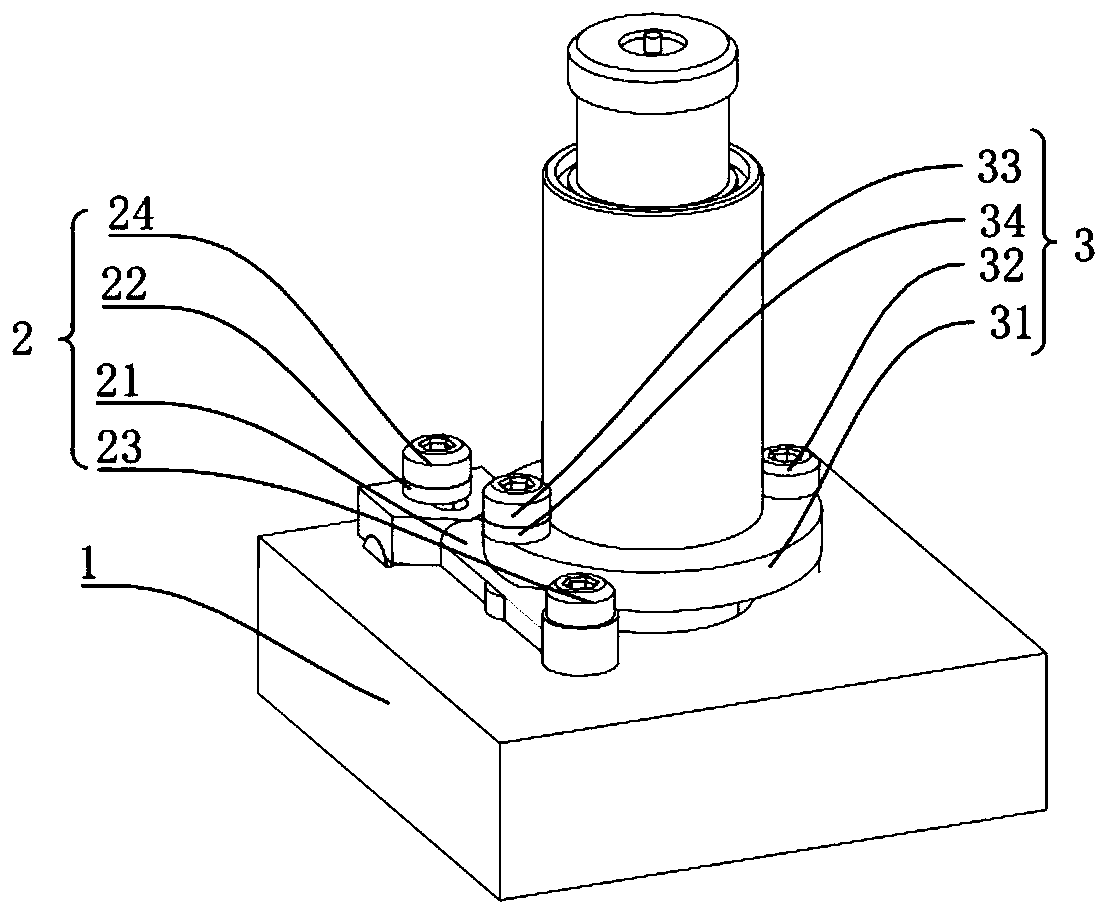

[0014] like figure 1 As shown, an angle adjustment mechanism includes a base 1 with a lens mounting hole, and a horizontal adjustment assembly 2 and a vertical adjustment assembly 3 are arranged on the base 1. The horizontal adjustment assembly 2 realizes The horizontal angle adjustment of the lens; the vertical adjustment component 3 realizes the vertical angle adjustment of the lens by changing the height difference between the vertical ends of the lens.

[0015] like figure 1 and figure 2 As shown, the horizontal adjustment assembly 3 includes an annular ring 31, an adjusting screw 32, a compression screw 33, and an elastic member 33 nested on the adjustment screw 32 and the compression screw 33. The annular ring 31 is detachably connected to the lens , the adjusting screw one 32 runs through the annular ring 31 and the elastic member 34, and is screwed to the base 1, wherein the elastic member one 34 on the adjusting screw one 32 is located between the annular ring 31 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com