Quick-connection structure

A connection structure and clamping groove technology, applied in the field of quick-connect structure and power device quick-connect structure, can solve the problem that electrical appliances or machinery cannot share the same power device, reduce the trouble of removing fasteners such as bolts, and improve the Efficiency, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

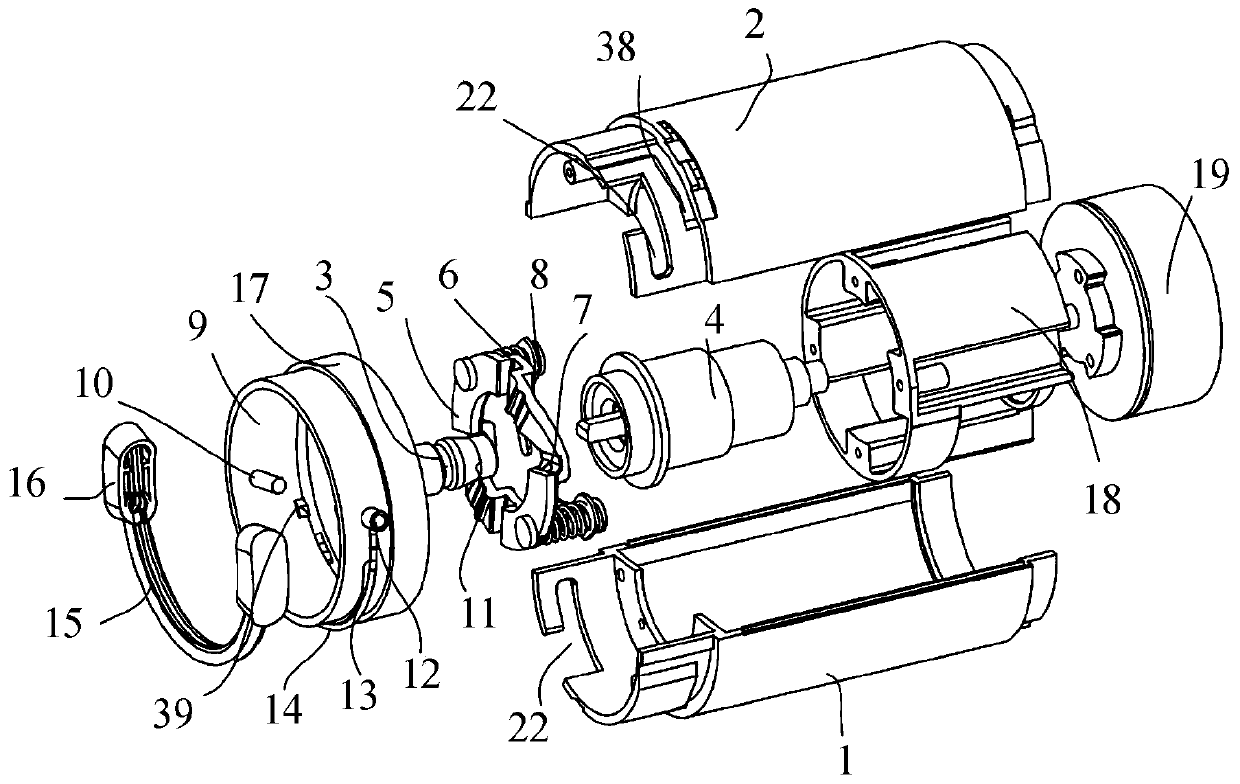

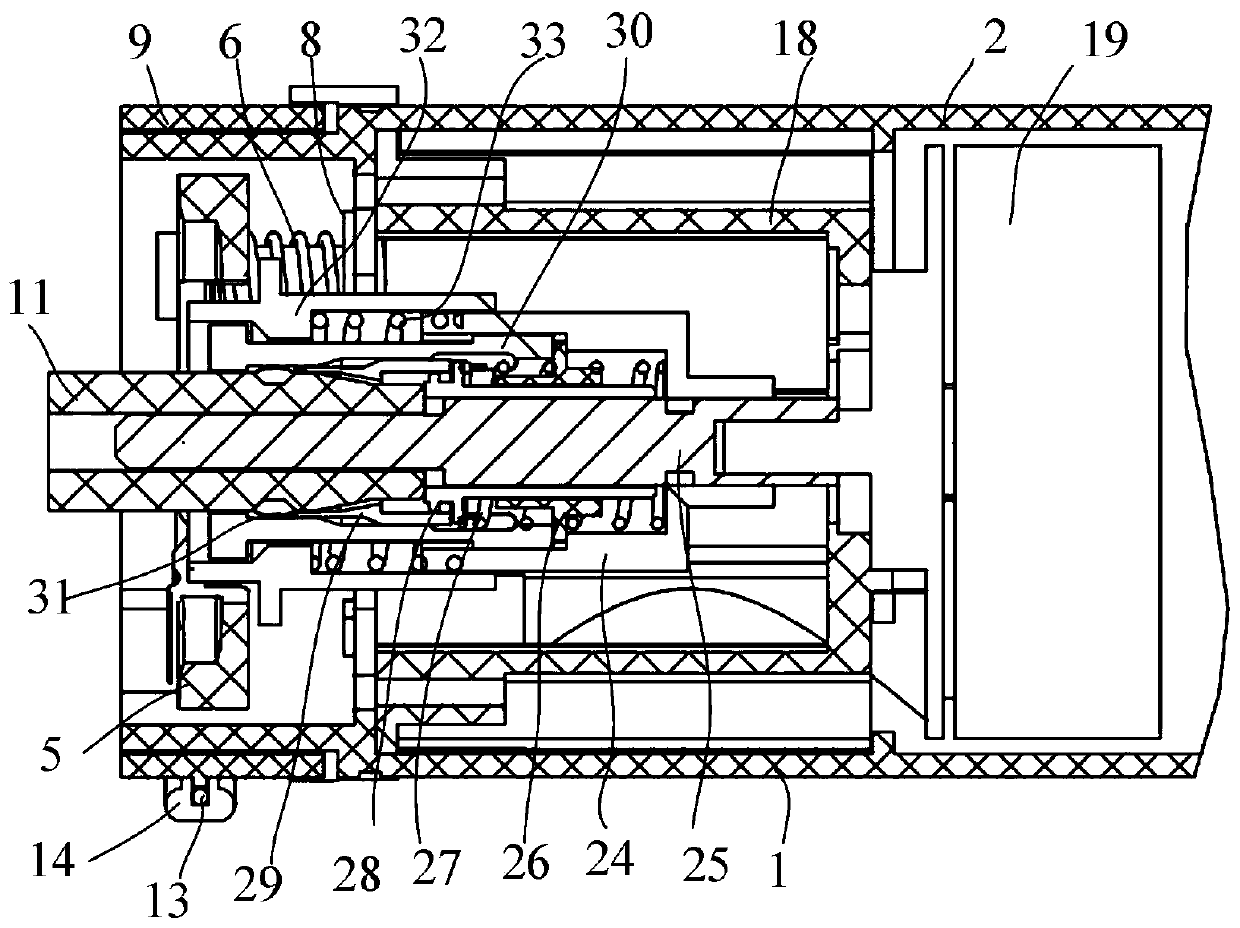

[0032] Such as Figure 1 to Figure 7 As shown, a quick-connect structure in this embodiment includes an upper housing 2, a lower housing 1, a power unit 19, an inner quick-connect assembly 4, a rotary stopper 5, two first springs 6, and a functional housing 9 and functional shaft sleeve 11; the upper casing 2 and the lower casing 1 are fastened and connected to form a casing part, and a first accommodation chamber is arranged in the casing part, and the power unit 19 is arranged in the first accommodation chamber, and the output shaft of the power unit 19 Insert one end of the inner quick-connect assembly 4, and the other end of the inner quick-connect assembly 4 is inserted into the functional bushing 11; the rotary stopper 5 is elastically connected to one end of the housing part through two first springs 6, and the housing The side wall located on the outside of the rotary baffle 5 is provided with two engagement grooves 22, and two engagement pins 10 are fixed on the inner...

Embodiment 2

[0036] Such as Figure 1 to Figure 7 As shown, a quick connection structure in this embodiment includes all the technical features in Embodiment 1. In addition, a plurality of barbs are also provided on the outer wall of the end of the shell part provided with the locking groove 22. Slot 38, a plurality of barb grooves 38 are located on the rear side of the engaging groove 22, a plurality of engaging protrusions 39 are arranged on the inner wall of the functional housing 9, and the number of the barb grooves 38 is the same as that of the engaging protrusions 39 ; when the locking pin 10 on the functional shell 9 is rotated and locked in the locking groove 22, the locking protrusion 39 on the functional shell 9 is correspondingly locked in the barb groove 38 to realize the connection between the functional shell 9 and the housing part. When the functional housing 9 is disassembled, the functional housing 9 is pushed towards the direction of the power unit 19, the functional bus...

Embodiment 3

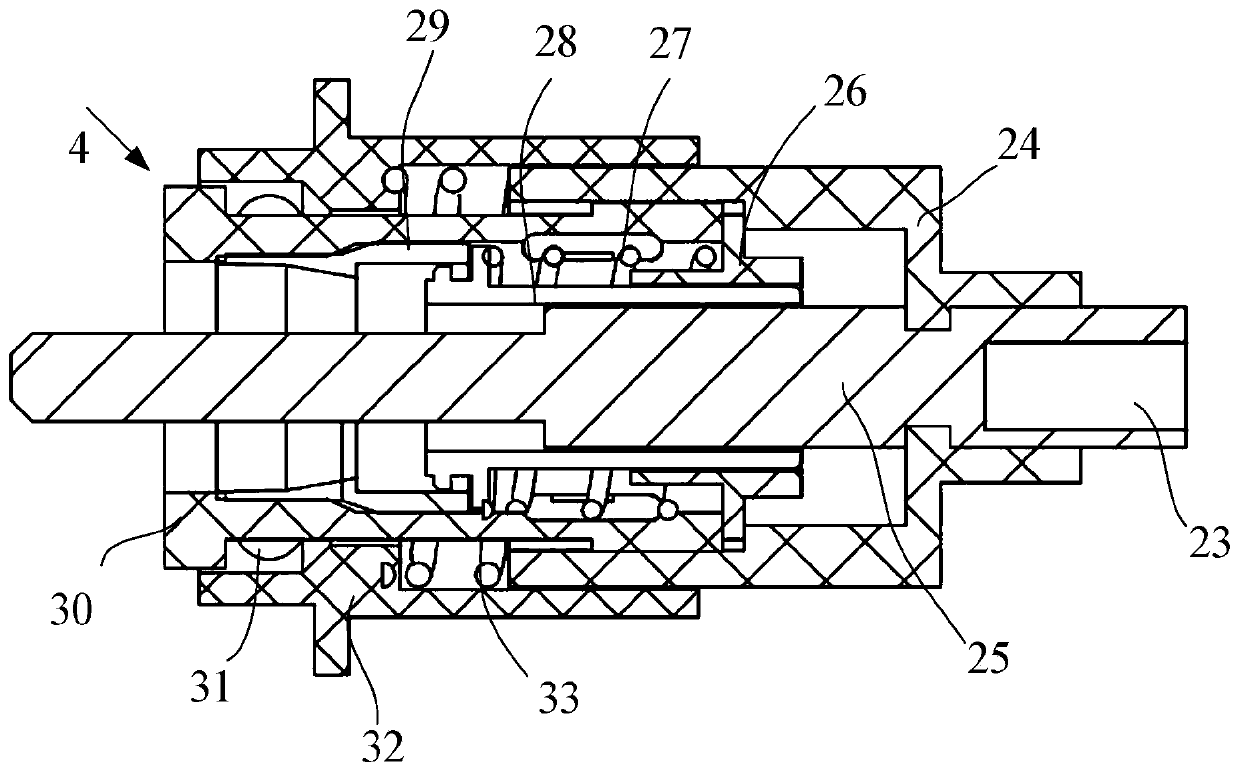

[0040] Such as Figure 1 to Figure 7 As shown, a quick-connect structure in this embodiment includes all the technical features in Embodiment 2. In addition, the inner quick-connect assembly 4 includes an inner quick-connect sleeve 24, an inner quick-connect shaft 25, an inner quick-connect Base 26, second spring 27, inner quick-connect spring post 28, inner quick-connect washer 29, inner quick-connect lower cover 30, multiple steel balls 31, inner quick-connect upper cover 32 and third spring 33; inner quick-connect sleeve 24 Fixed on the outer peripheral side of the inner quick-connect shaft 25, one end of the inner quick-connect shaft 25 is provided with a motor shaft hole 23, the output shaft of the power unit 19 is plugged in the motor shaft hole 23, and the other end outer wall of the inner quick-connect shaft 25 An annular accommodation cavity is formed between the inner quick-connect sleeve 24 , the inner quick-connect base 26 is sleeved on the outer peripheral side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com