Shaped groove slotting machine

A technology of slotting machine and special-shaped slot, applied in slotting machines, mortising machines, manufacturing tools, etc., can solve problems such as low efficiency, difficult processing, unstable product quality, etc., to improve work efficiency and ensure stability. Sex, the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

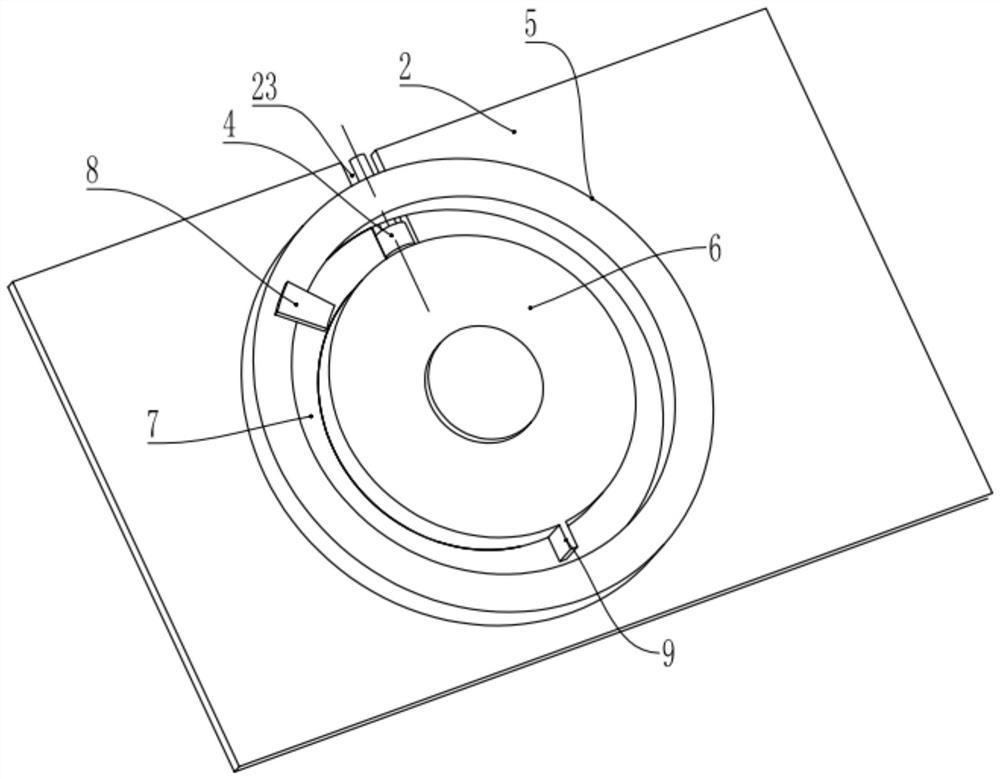

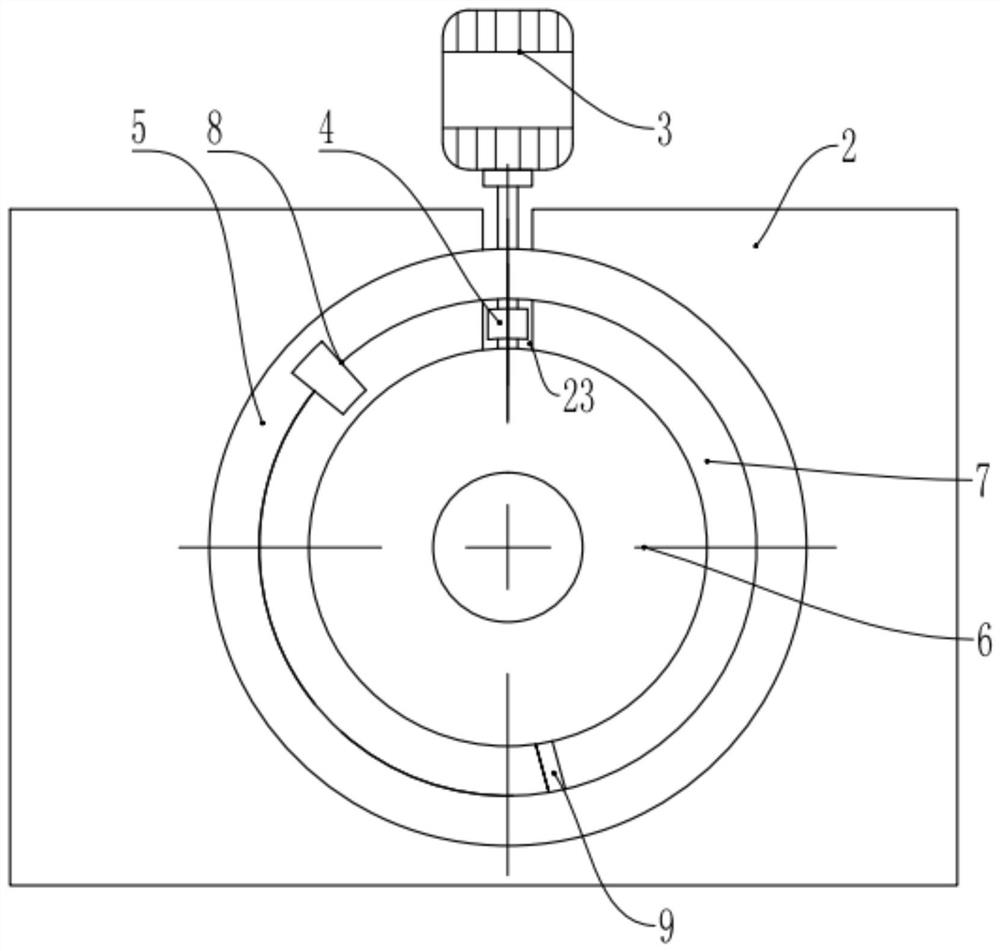

[0034] Embodiment one is basically as attached figure 1 and figure 2 Shown:

[0035] The special-shaped groove slotting machine includes a frame 1, an operation table 2 and a cutting unit. The cutting unit includes a motor one 3 and a cutting knife 4. The motor one 3 drives the cutting knife 4 to rotate on a vertical plane; the operation table 2 is fixed by screws Connected with formwork 5, rotating on the console 2 is connected with a turntable 6, the turntable 6 passes through the console 2, motor two is installed on the frame 1, the motor two drives the turntable 6 to rotate in the horizontal plane, the formwork 5 is ring-shaped, and the mold An annular groove 7 is formed between the frame 5 and the turntable 6 to facilitate the placement of the workpiece 24. A cutting through groove 23 is provided on the operating table 2, and the cutting through groove 23 is facing the center of the annular groove 7; the top of the mold base 5 is fixed by screws A briquetting block 8 f...

Embodiment 2

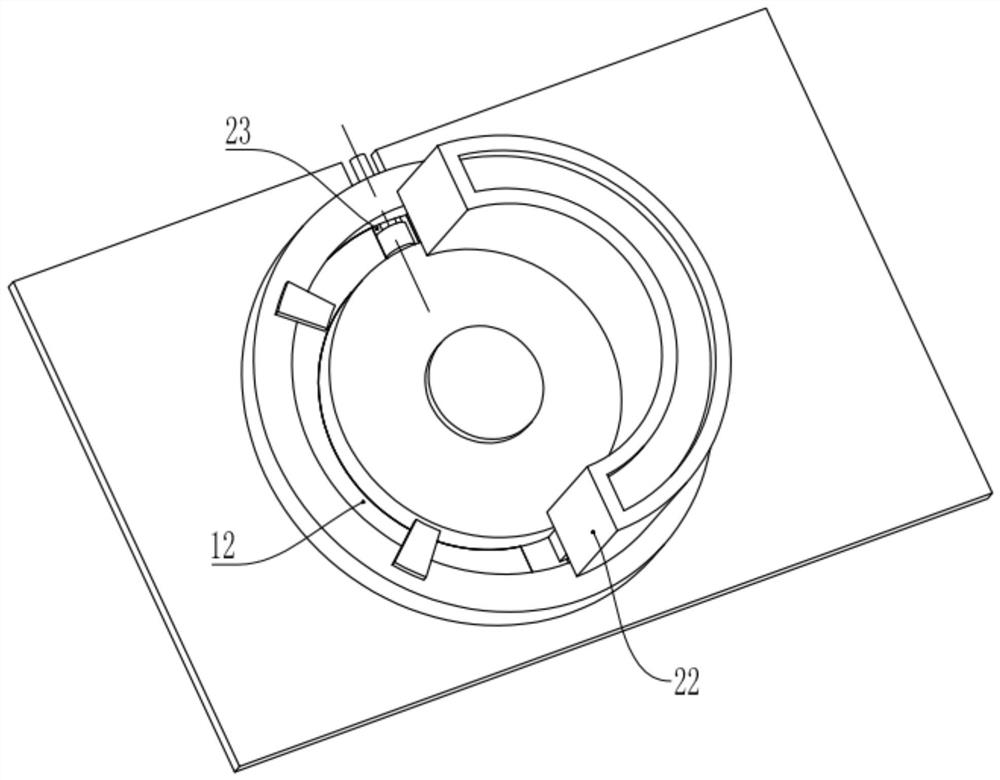

[0040] Embodiment two is basically as attached Figure 3 to Figure 9 As shown, embodiment two has carried out following improvement on the basis of embodiment one:

[0041] combine image 3 , Figure 4 , Figure 5 and Figure 9 , also includes a lift unit and a push-out unit installed at the bottom of the console 2, the lift unit includes a cylinder 10 and a lift rod 11 (the lift rod 11 is the piston rod of the cylinder 10), and the cylinder 10 drives the lift rod 11 to move up and down; the lift rod 11 Placement table 12 is provided above, and operation platform 2 is provided with avoidance hole (cutting through groove 23 communicates with avoidance hole, combines Figure 5 ), the placement platform 12 is located directly below the escape hole, and the placement platform 12 can rise to be flat with the upper surface of the operating platform 2 .

[0042] combine Figure 7 , the lifting rod 11 is fixedly sleeved with a connecting ring 13 by screws, and the connecting rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com