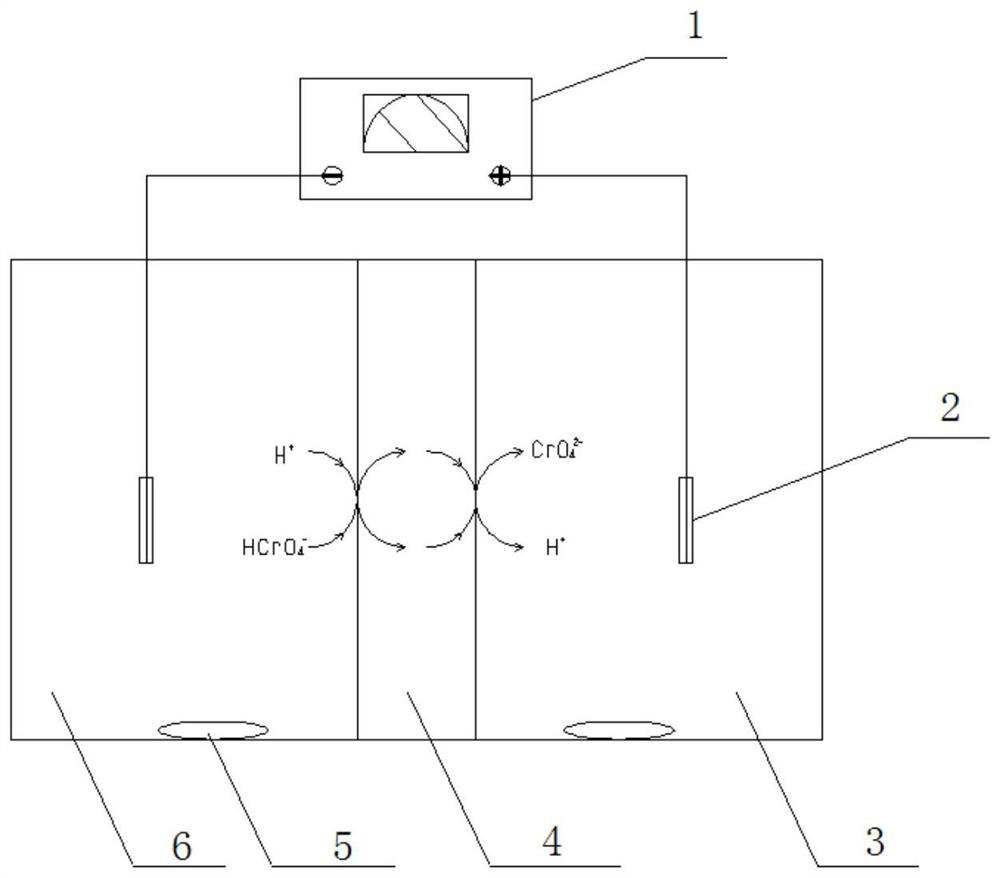

A kind of deep purification method of low concentration heavy metal chromium (vi)

A low-concentration heavy metal, deep purification technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of slow mass transfer rate of solid-phase liquid film, etc., to achieve easy industrial expansion, low electric field voltage, no The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In terms of mass percentage, 3.43% of polyvinylidene fluoride-hexafluoropropylene copolymer, 17.16% of tributyl phosphate, and 79.41% of tetrahydrofuran were magnetically stirred until a homogeneous transparent casting solution was formed, and the casting solution was poured Put it into a flat-bottomed airtight container placed horizontally, communicate with the atmosphere, and volatilize at 25°C to constant weight to obtain a solid-phase liquid film. The shear thickness is 100μm, and the effective membrane area is 3.14cm 2 The liquid membrane is fixed to the central connection part of the osmosis device. Remove the chromium (VI) 12mg / L, pH 1.3, volume 80mL chromium solution at a voltage of 10V, and set the concentration of the analytical phase to 0.5mol L -1 Sodium acetate solution, the volume is 40ml. The magnetic stirring speed is controlled to be 300rmp. After 8 hours of continuous extraction, the concentration of chromium (VI) in the liquid phase of the material ...

Embodiment 2

[0039] In terms of mass percentage, 3.56% polyvinyl chloride, 14.21% tributyl phosphate, 5.0% lauryl alcohol, and 77.23% tetrahydrofuran are co-dissolved, magnetically stirred to a homogeneous transparent casting solution, and the casting solution is poured into Placed horizontally in a flat-bottomed airtight container, open to the atmosphere, volatilize at 35°C to constant weight to obtain a solid-phase liquid film. The cutting thickness is 100μm, and the effective membrane area is 3.14cm 2 The solid-phase liquid film is fixed on the central connecting part of the two mass transfer devices. The volume is 80mL, the pH is 1.3 (hydrochloric acid), the concentration is 12mg / L chromium (Ⅵ) solution is enriched, the volume is 40ml, the acetic acid / sodium acetate buffer solution of pH is 5 is analytical phase. Control the two-phase magnetic stirring speed to 300rmp, and the voltage to 10V. After 12 hours of continuous extraction, the concentration of chromium (Ⅵ) in the feed liquid...

Embodiment 3

[0041] By mass percentage, after mixing 4.0% polyvinyl chloride, 3.0% trioctyl phosphine oxide (TOPO), and 1 / 1 mixture of 93.0% chloroform and tetrahydrofuran, stir with magnetic force until forming a uniform transparent solution, pour Put it horizontally in a flat-bottomed airtight container with a thickness of 1mm, keep it open to the atmosphere, and volatilize at 30°C to constant weight to obtain a solid-phase liquid film with a thickness of 120um. After taking it out, fix it to the central connection part of the osmosis device. The effective membrane area is 3.14cm 2 , with a thickness of 150 μm. Adjust the pH of the low-concentration chromium (VI)-containing aqueous phase containing 12 mg / L chromium (VI) with a volume of 80 ml to 1.3 with hydrochloric acid as the feed liquid phase, and the concentration is 0.1mol L -1 The sodium hydroxide solution is used as the analytical phase, and the volume of the two phases is 80ml. Control the two-phase magnon speed to 300rmp, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com