Anti-rollover locking metal support

An anti-rollover and locking technology, applied in the direction of bridge parts, bridges, buildings, etc., can solve the problem of inability to adapt to the elongation and contraction of the beam body, the support cannot be practically used in the viaduct, and the beam body of the viaduct cannot be prevented from rolling over, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] There are two technical solutions for the anti-rollover locking metal support:

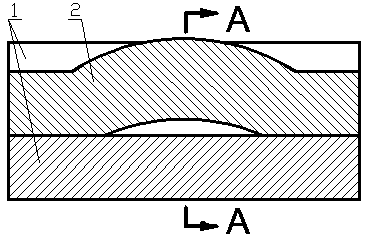

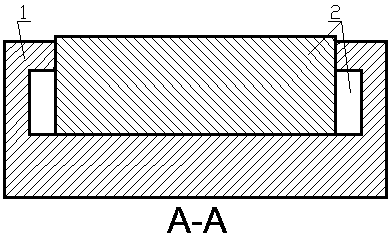

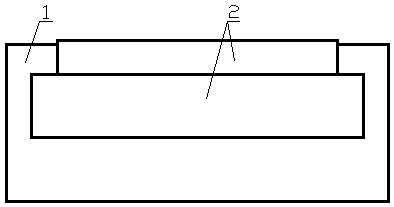

[0081] 1. The anti-rollover locking metal support includes an elastic slide plate 2 composed of a curved plate 7 and a straight plate 8 or a curved plate, a sliding guide part on the elastic slide plate 2, a lateral limit part, a locking limit part 5, and a bearing part The formed guide slide body 1, the guide slide groove 6 on the guide slide base body 1;

[0082] There is a long opening on the long side so that the cross section of the rectangular tubular guide slide body 1 is a convex guide slide groove 6, and an elastic slide plate 2 and an arc-shaped plate 7 of the elastic slide plate 2 are installed in the guide slide groove 6 The top of the top is higher than the upper end of the guide slide seat body 1, the guide slide part of the elastic slide plate 2 is wider than the arc plate 7, and the guide slide part is between the locking limit part 5 of the guide slide groove 6 and the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com