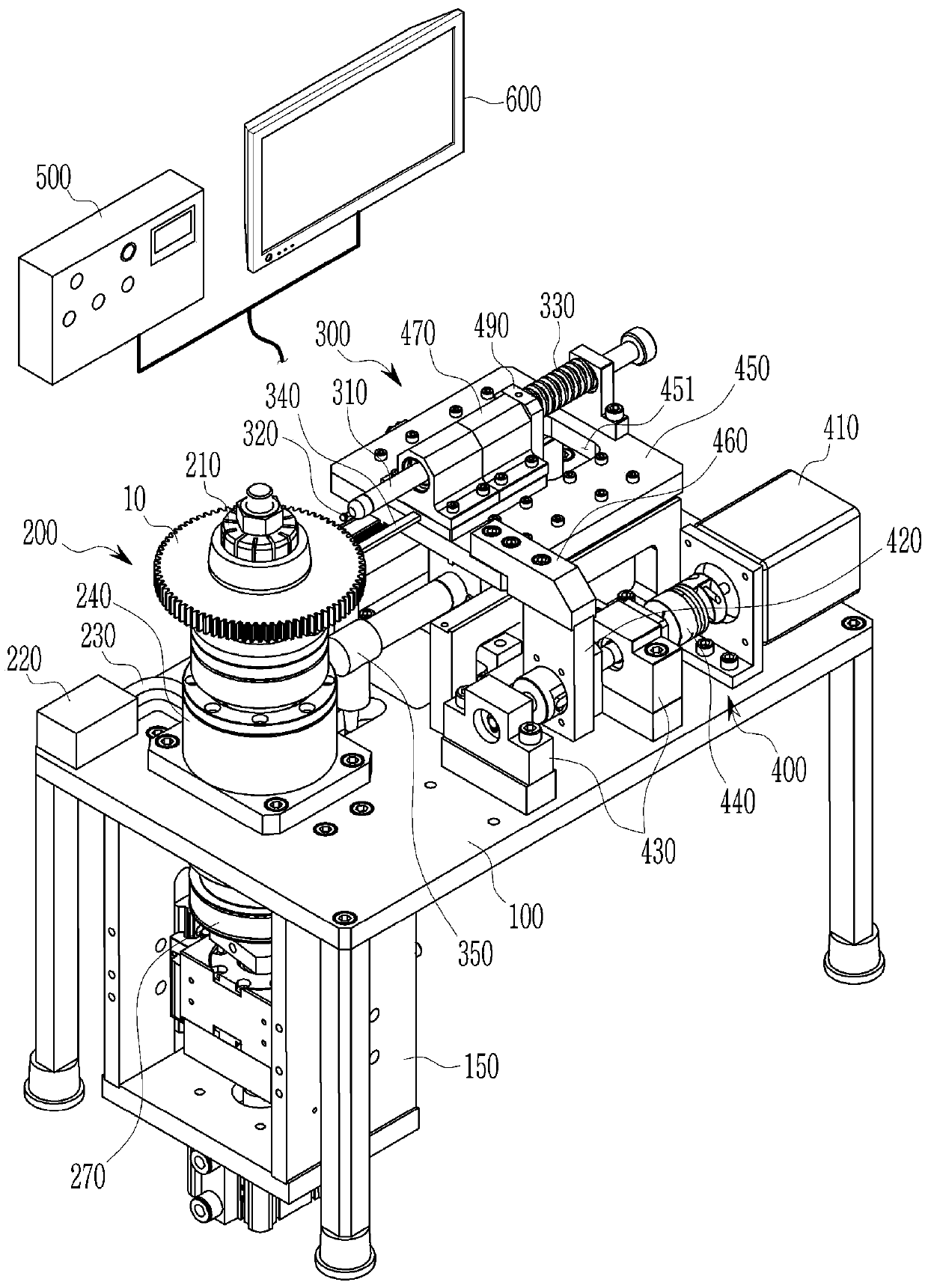

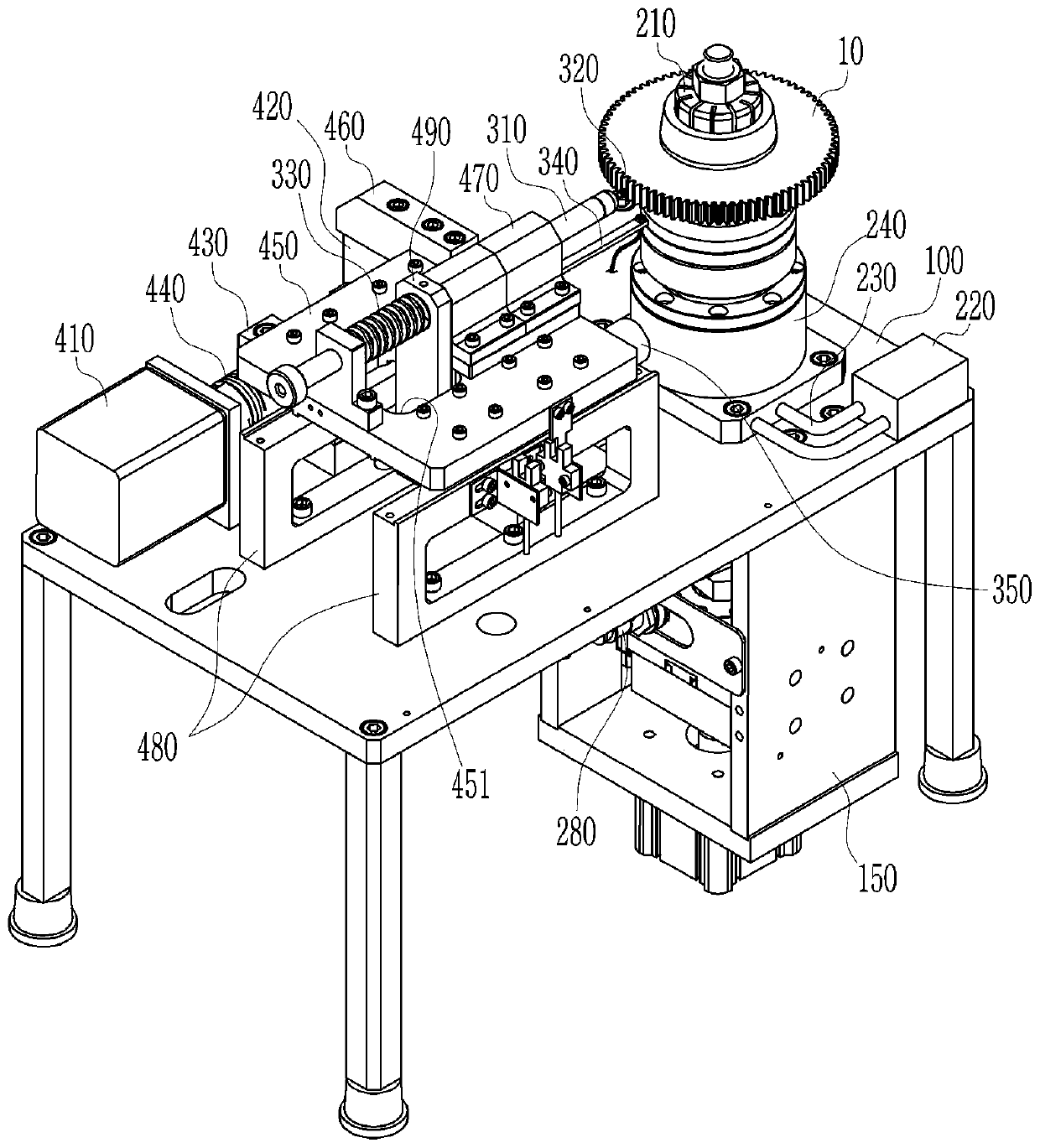

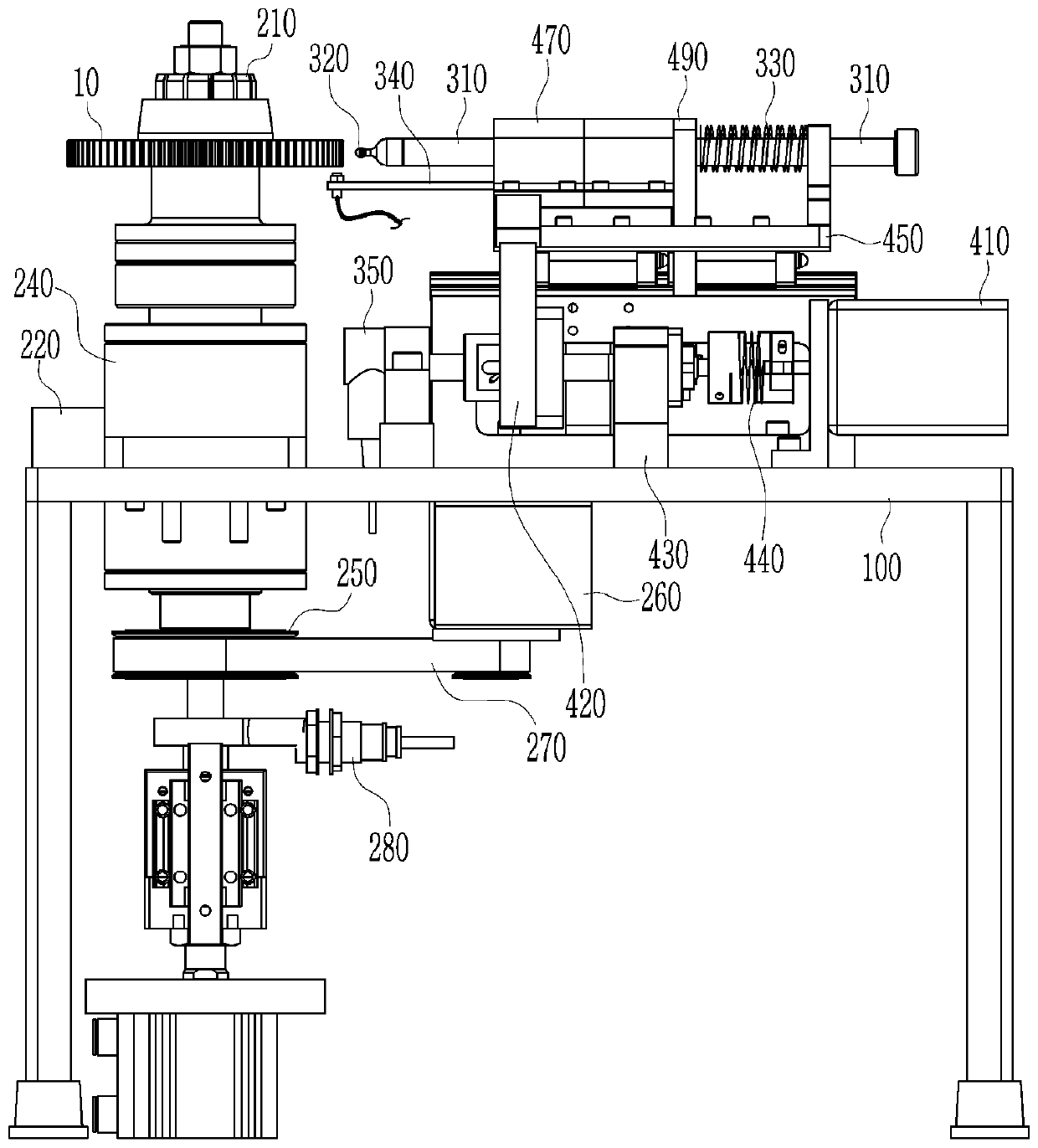

Gear inspection apparatus and gear inspection method using the same

A technology for gear inspection and gear teeth, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, can solve problems such as manual rotation, improve inspection speed, improve working environment and machinability, and improve inspection reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The following description is merely exemplary in nature and is not intended to limit the invention, application or uses. It should be understood that throughout the specification and drawings, corresponding reference numerals indicate like or corresponding parts and features.

[0072] Therefore, the exemplary forms disclosed in the present invention and the configurations shown in the drawings are only exemplary forms of the present invention, and do not represent all technical spirits of the present invention. Therefore, it should be understood that various equivalents and modified examples that can replace the illustrated forms can be made at the time of filing the application.

[0073] Components irrelevant to the description will be omitted to clearly describe the present invention, and the same or similar constituent elements will be denoted by the same reference numerals throughout the present invention.

[0074] The size and thickness of each component shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com