Patents

Literature

121results about How to "Limit the scope of protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

New method for synthesizing 3-cyclopropyl methoxy-4-(difluoromethoxy) benzoic acid

InactiveCN102093194AHigh purityHigh yieldPreparation from carboxylic acid esters/lactonesAlkyl transferBenzoic acid

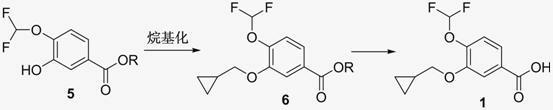

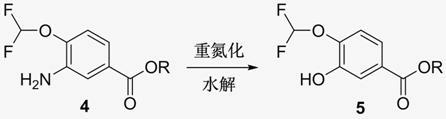

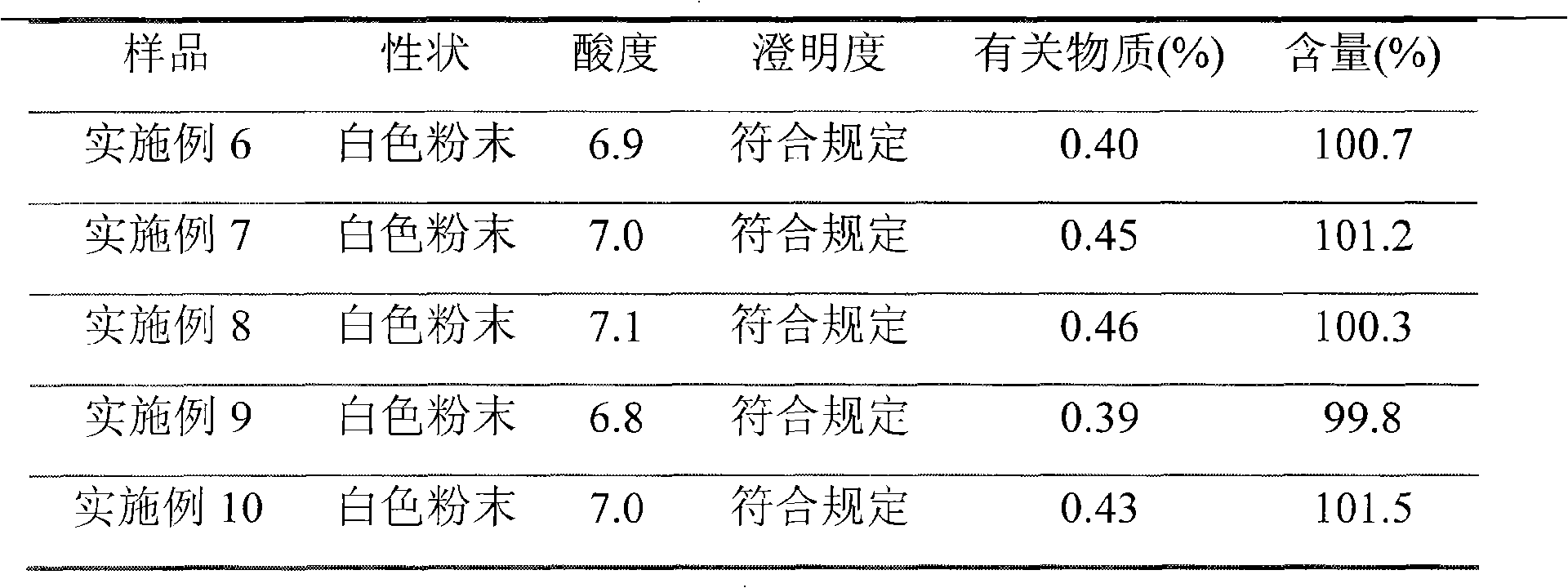

The invention relates to a new method for synthesizing 3-cyclopropyl methoxy-4-(difluoromethoxy) benzoic acid. The method is characterized by taking 3-nitro-4-hydroxybenzoic acid ester as the raw material to obtain the 3-cyclopropyl methoxy-4-(difluoromethoxy) benzoic acid through alkylation, reduction, diazotization, hydrolysis, alkylation, deprotection and the like. The 3-cyclopropyl methoxy-4-(difluoromethoxy) benzoic acid is a key intermediate for synthesizing the drug roflumilast.

Owner:NANJING SIMCERE MEDICAL LAB CO LTD +1

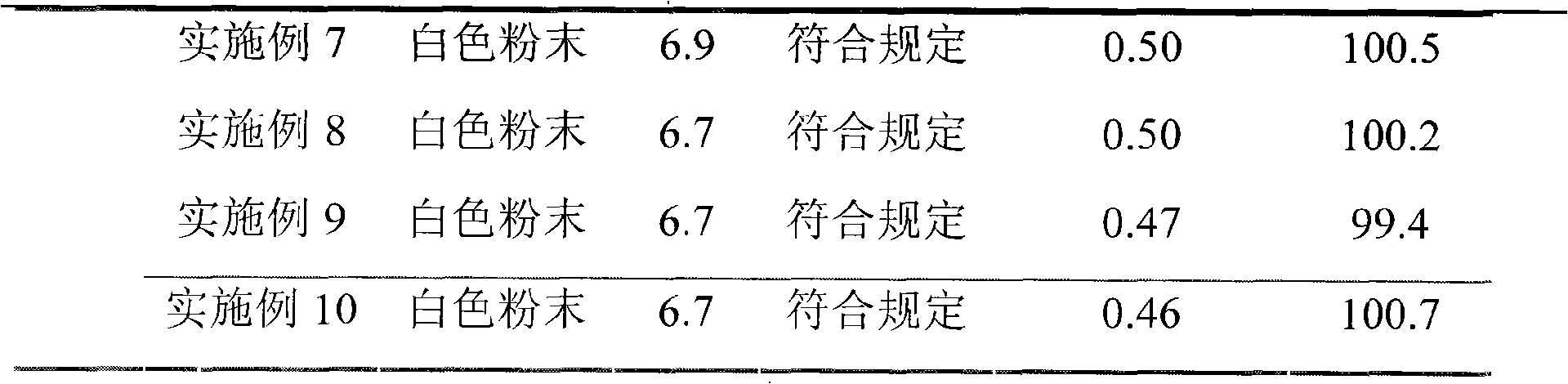

High-purity ceftizoxime sodium and preparation thereof

InactiveCN101348492AHigh purityNo pollution in the processAntibacterial agentsPowder deliveryCeftizoxime SodiumInorganic chemistry

Owner:HAINAN LINGKANG PHARMA CO LTD

Preparation method of polyamide hot melt adhesive with low surface energy for hot drills

InactiveCN103524731AHigh bonding strengthHigh strengthNon-macromolecular adhesive additivesPolymer sciencePolyamide

The invention discloses a preparation method of a polyamide hot melt adhesive with low surface energy for hot drills. The preparation method comprises the following steps: adding aliphatic dicarboxylic acids, aliphatic diamines, other diamines, C6-12 lactam, nylon 66 salt, a molecular weight regulator and a modifier into a high pressure reaction kettle; and carrying out polymerization reaction under a condition of a certain temperature and pressure to obtain a targeted product. The product is applicable to adhering materials with low surface energy and particularly applicable to adhering hot drills with low surface energy such as a resin drill.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

New technology for refining Fischer-Tropsch synthesis light fraction oil

InactiveCN106753546AReduce volatile lossEasy extractionTreatment with plural serial refining stagesSolid phase adsorptionImpurity

The invention relates to a new technology for refining Fischer-Tropsch synthesis light fraction oil. The new technology comprises solid-phase adsorption, extraction refining, separation and extraction agent refining and a recycling unit. In the new technology for refining Fischer-Tropsch synthesis light fraction oil provided by the invention, Fischer-Tropsch synthesis light fraction oil is used as a raw material; metal ion impurities and oxygenated compounds in the Fischer-Tropsch synthesis light fraction oil are removed by the technology unit while the recycled refined extraction agent is circularly utilized. The new technology for refining Fischer-Tropsch synthesis light fraction oil provided by the invention has the advantages of simple process, high recycling efficiency, recycling and cyclic utilization of extraction agent, low cost of extraction agent, small investment, and the like.

Owner:LUOYANG HEMENG TECH CO LTD

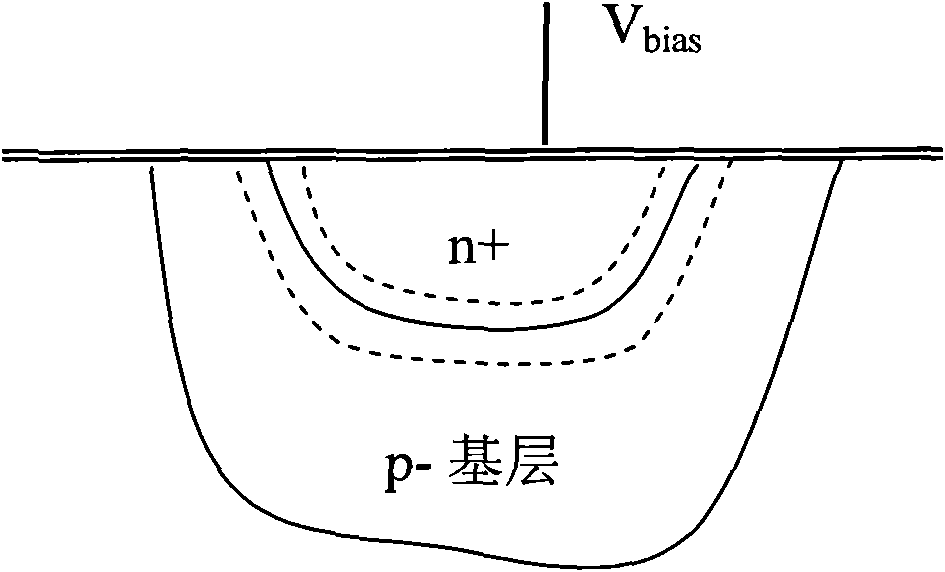

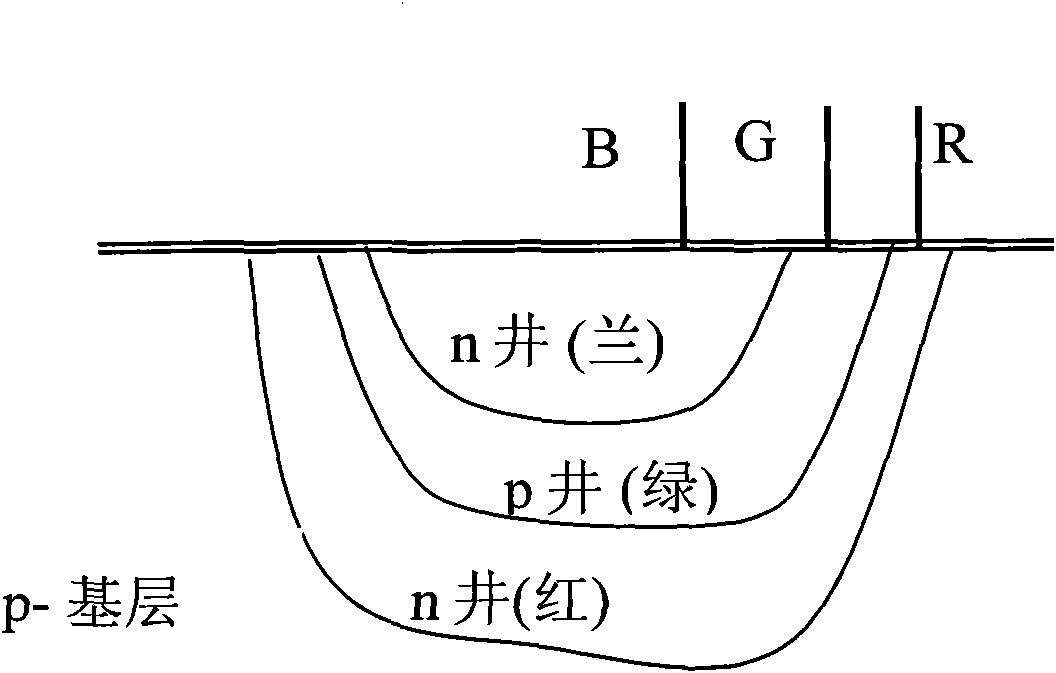

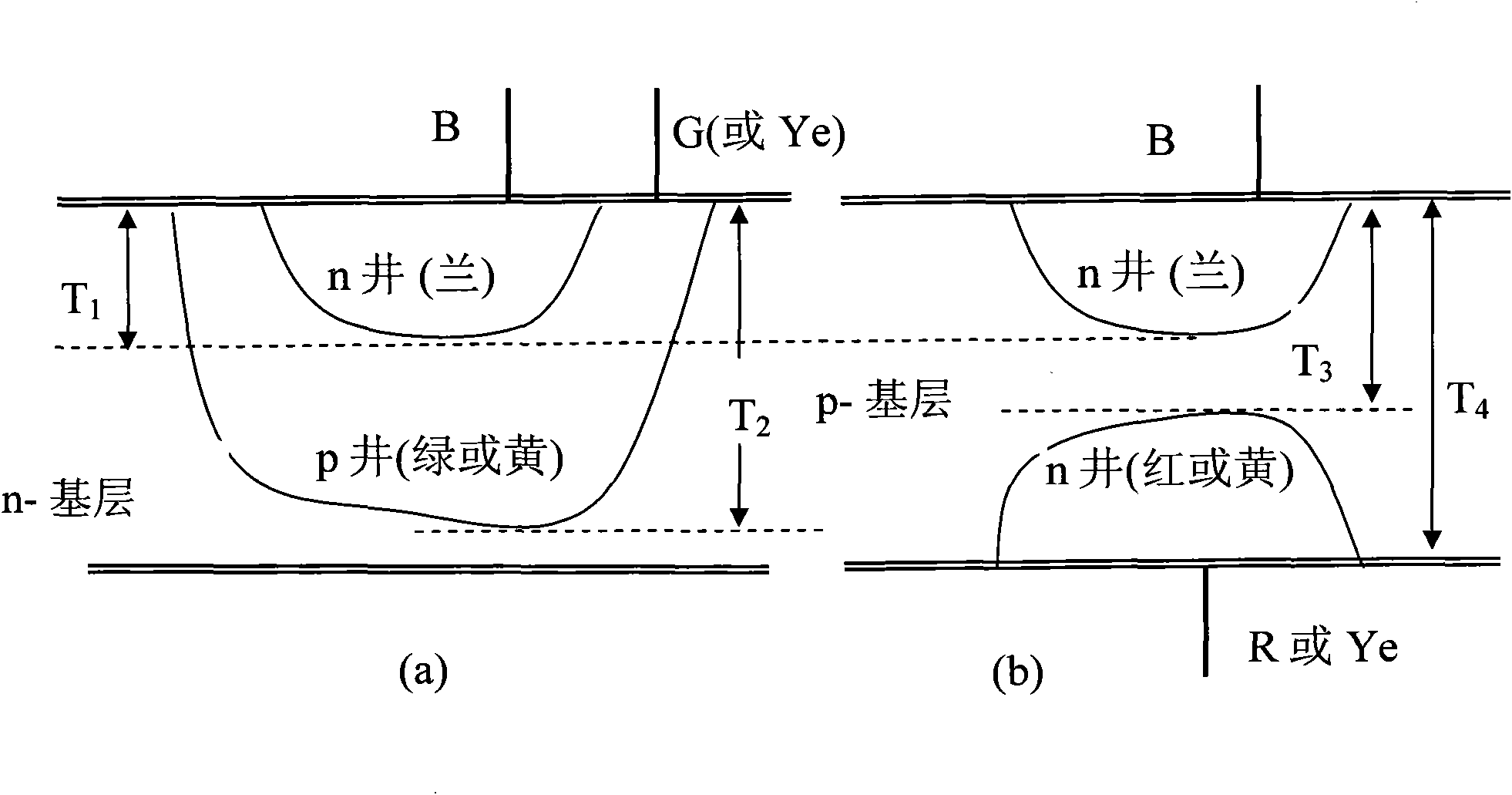

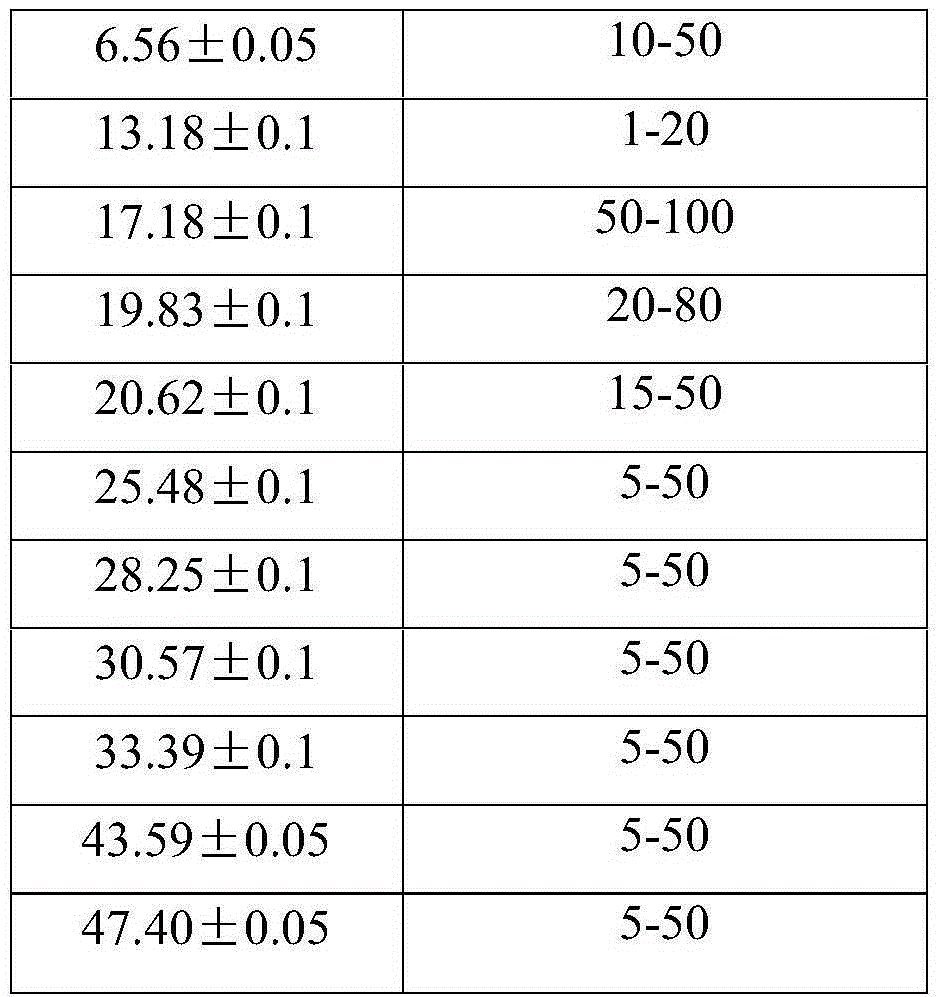

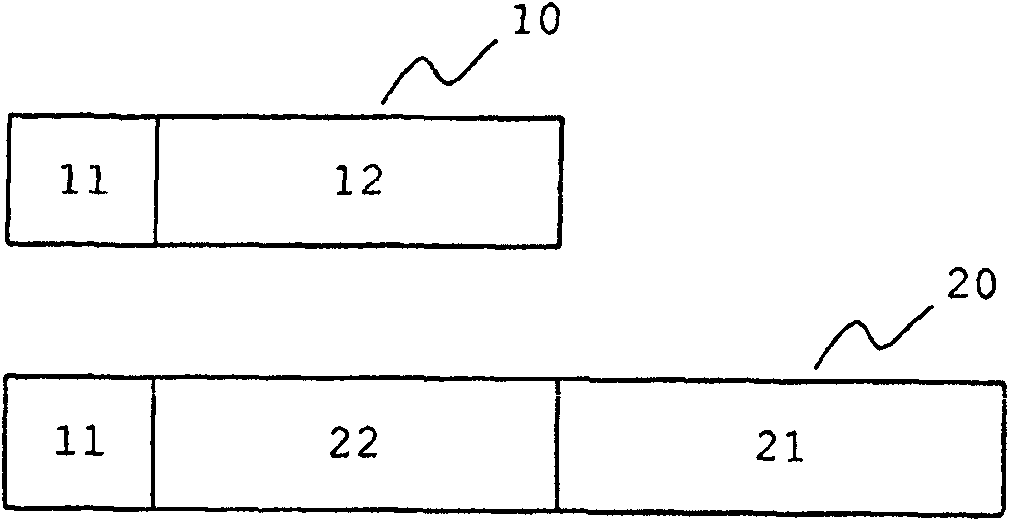

Multispectral photosensitive component

ActiveCN101807590AGood color sensitivityGood flexibilityTransistorSolid-state devicesMachining processVisible spectrum

The invention relates to a multispectral photosensitive component which comprises multilayer composite photosensitive pixels which adopt a single-face or double-face machining mode, realize up-down placement in a silicic P or N basic layer in two, three or four and respectively induct spectra which are orthogonal or complementary in visible light or visible and infrared light spectra. Basic photosensitive pixels on different levels in the composite photosensitive pixels can be designed to induct different colors or spectra, therefore, a multispectral photosensitive chip is obtained by repeatedly arranging a macro unit comprising more than one composite photosensitive pixel. The multispectral photosensitive component comprises a new design of the multilayer photosensitive pixels and examples thereof used for single-face double-layer, double-face double-layer, double-face three-layer, double-face four-layer, single-face mixed double-layer and double-face mixed double-layer or multilayermultispectral photosensitive components. The multispectral photosensitive component has more favorable colored photosensitive property and colored photosensitive and infrared photosensitive integration and simple machining process.

Owner:BOLY MEDIA COMM SHENZHEN

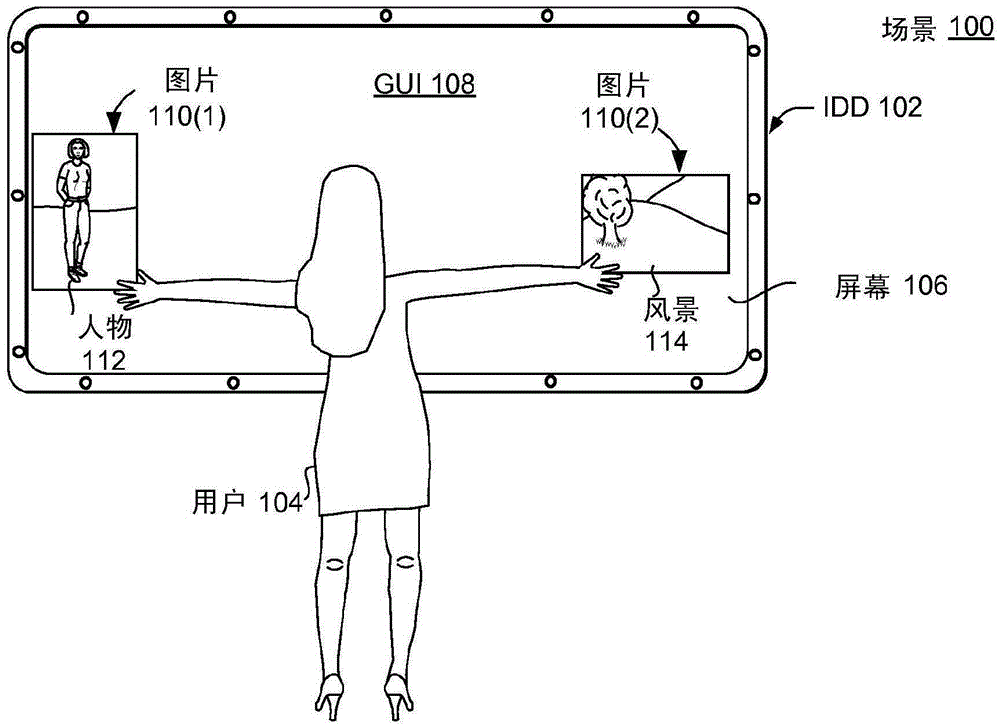

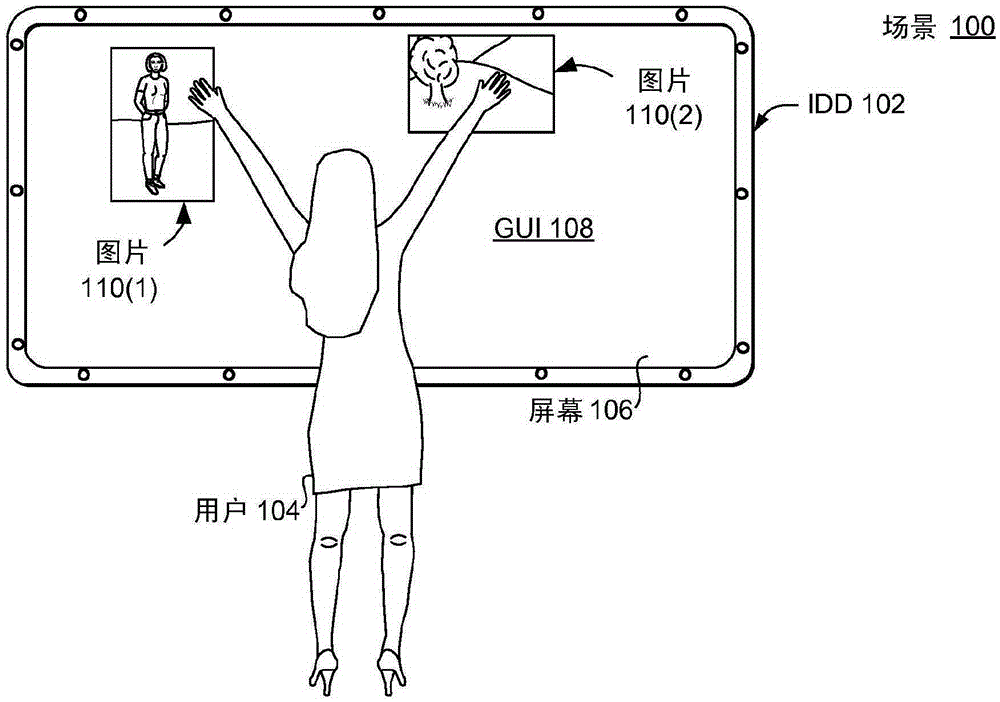

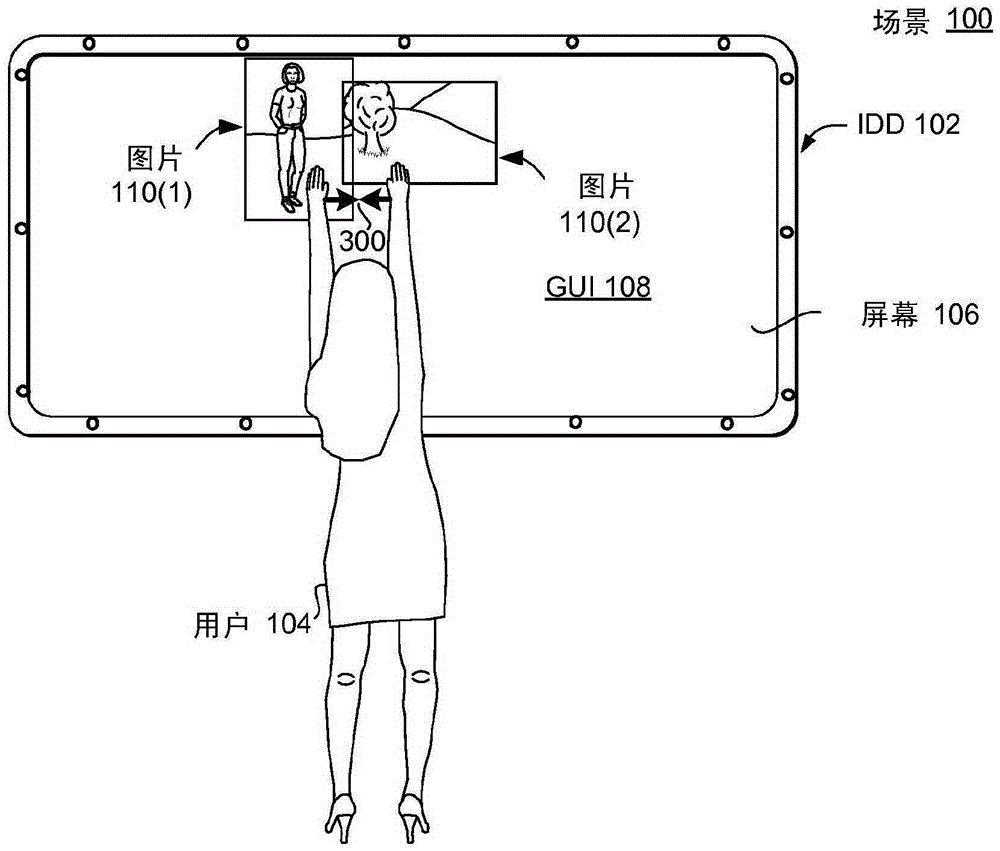

Interactive digital displays

ActiveCN105378599ALimit the scope of protectionInput/output for user-computer interactionDrawing from basic elementsGraphicsGraphical user interface

The description relates to an interactive digital display. One example includes a display device configured to receive user input and recognize commands relative to data visualizations. The system also includes a graphical user interface configured to be presented on the display device that allows users to interact with the data visualizations via the user commands.

Owner:MICROSOFT TECH LICENSING LLC

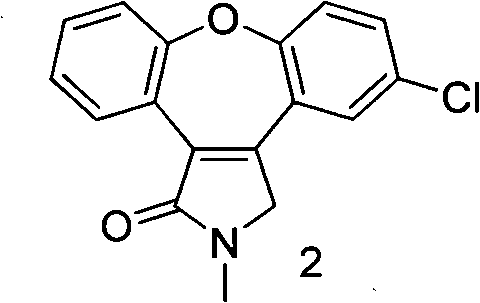

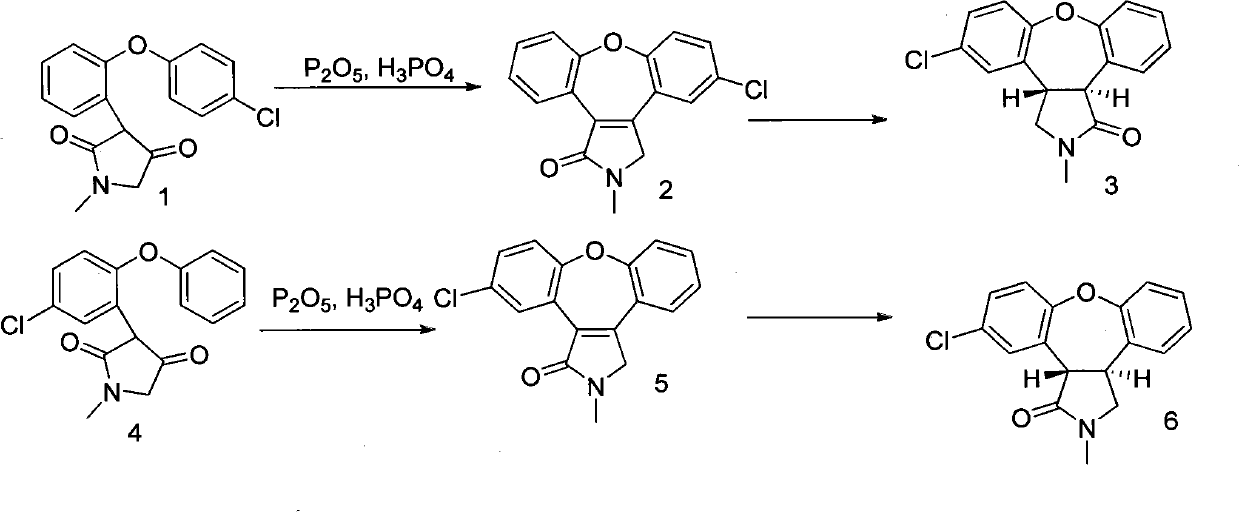

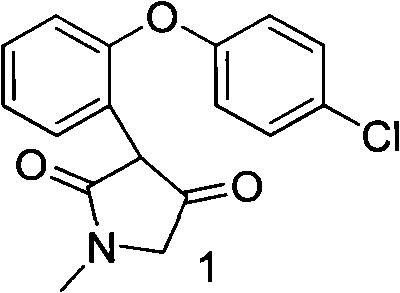

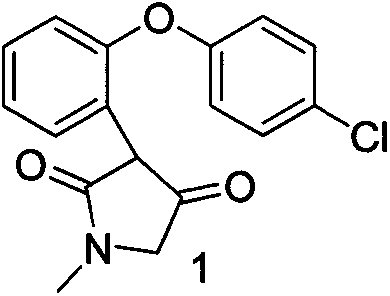

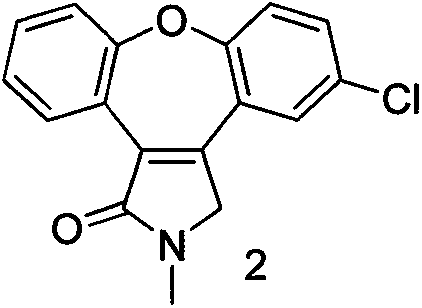

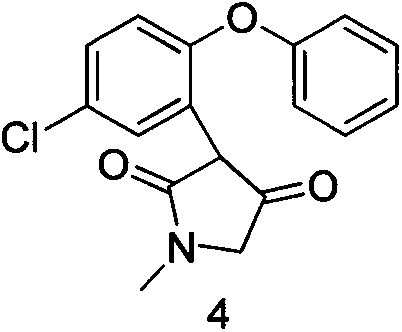

Preparation method of asenapine intermediate

ActiveCN101851242ANovel process routeReasonable process conditionsOrganic chemistryTriflic acidKetone

The invention discloses a novel preparation method of an asenapine intermediate, comprising the following steps of: carrying out cyclization in protonic acid including trifloromethanesulfonic acid by taking 3-(2-(4- chlorophenoxyl)-phenyl-4-hydroxyl-1-methyl-1H-pyrrole-2(5H)-ketone (compound 1) or 3-(5-chlorine-2-phenoxyl phenyl)-1-methyl-1H-pyrrole-2(4H)-ketone (compound 4) as a raw material to generate key intermediate compounds 2 and 4 of asenapine; and carrying out reduction reaction to obtain asenapine. The invention has the advantages of novel process route, high reaction yield and low production cost, and has greater application value and social economic effect.

Owner:SHANGHAI HAOYUAN MEDCHEMEXPRESS CO LTD

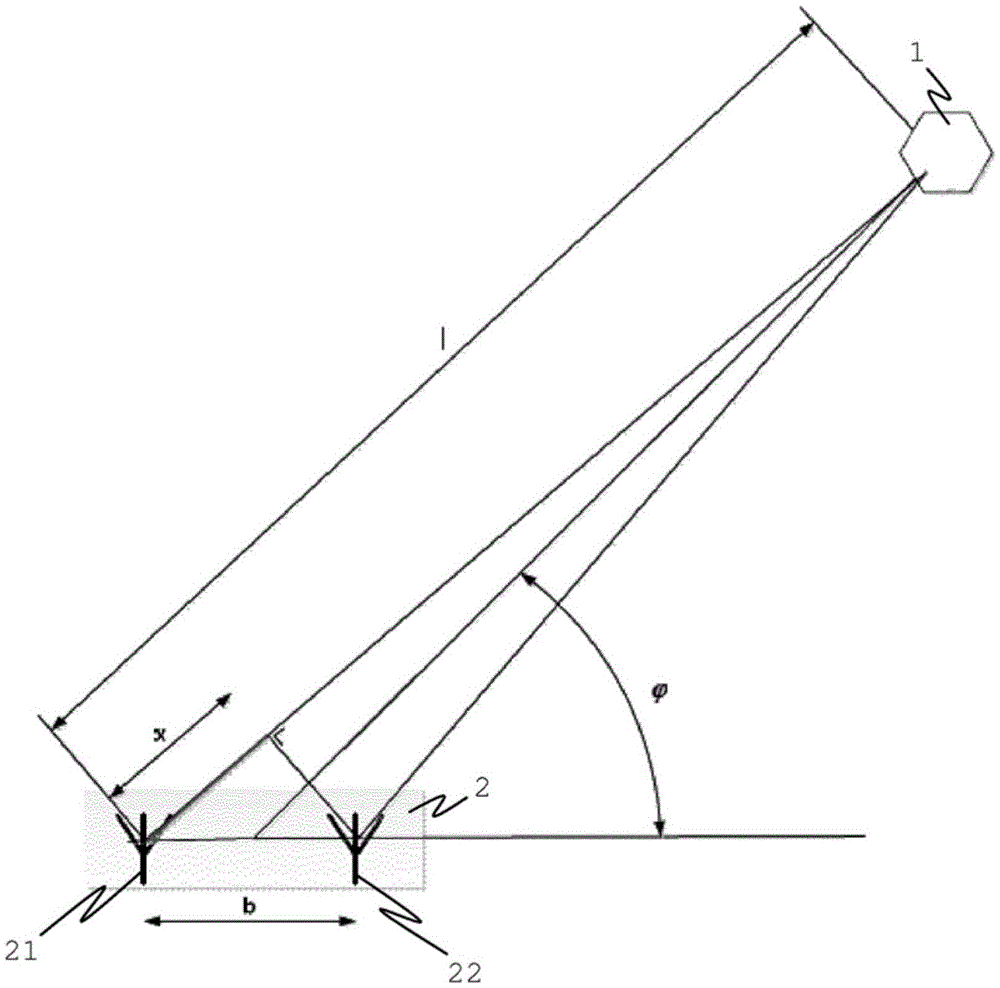

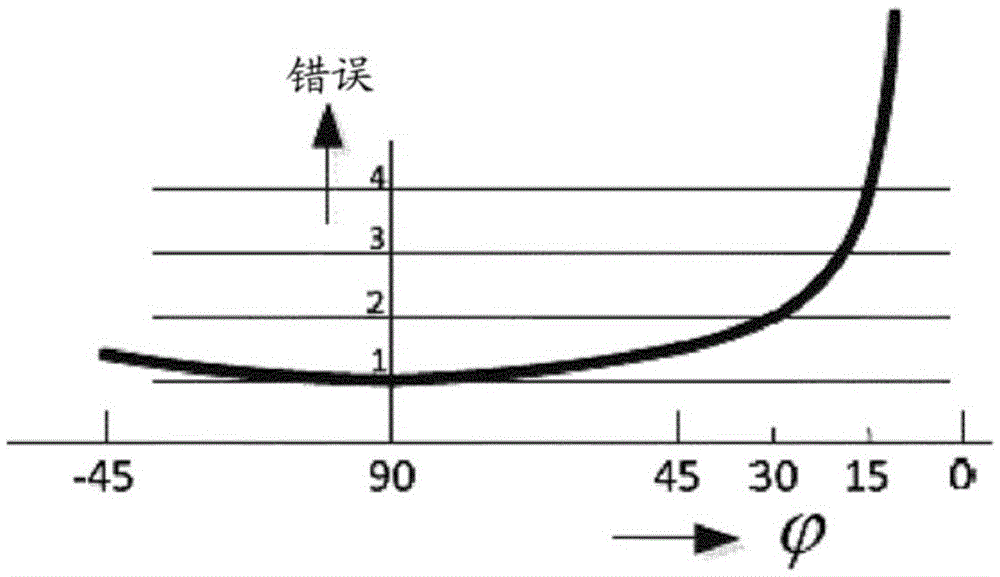

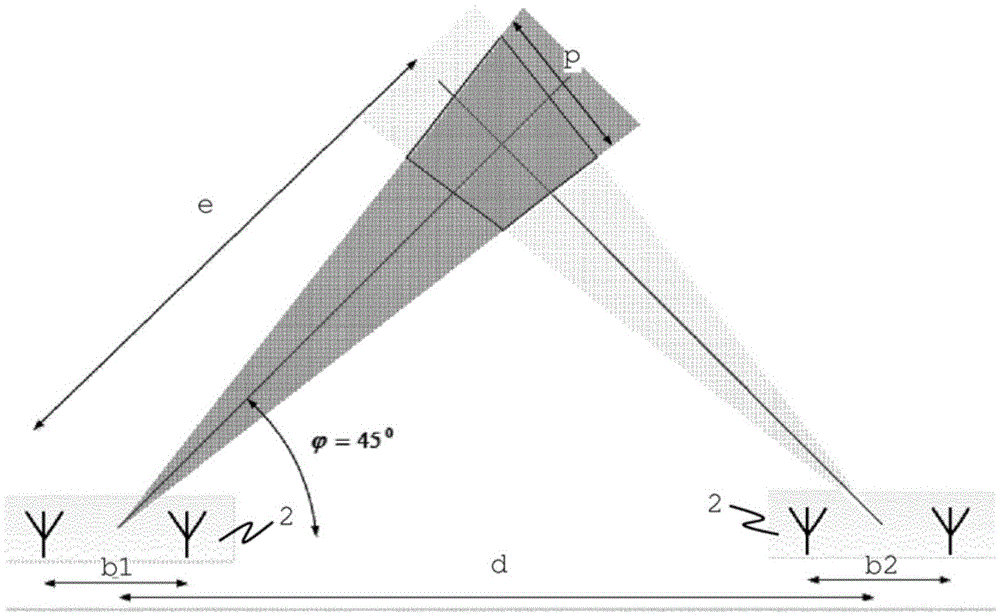

Locating a tag in an area

InactiveCN105556331APrecise time measurementAccurate Time Difference CalculationPosition fixationDirection findersUltra-widebandTag antenna

A method and system are proposed for locating a tag. The system comprises a first receiver configured to receive a signal from a tag. The first receiver comprises at least two antennas each configured to receive the signal and a first processing means configured to calculate a first angle of arrival of the signal at the first receiver based on a distance between a first set of two antennas of the first receiver and a time difference of arrival of the signal at the two antennas of the first set. The tag comprises a tag antenna that is configured to transmit signals having a wide bandwidth and has a frequency independent phase center and wherein the signal is an ultra wideband signal comprising one or more pulses.

Owner:BEESTAR BV

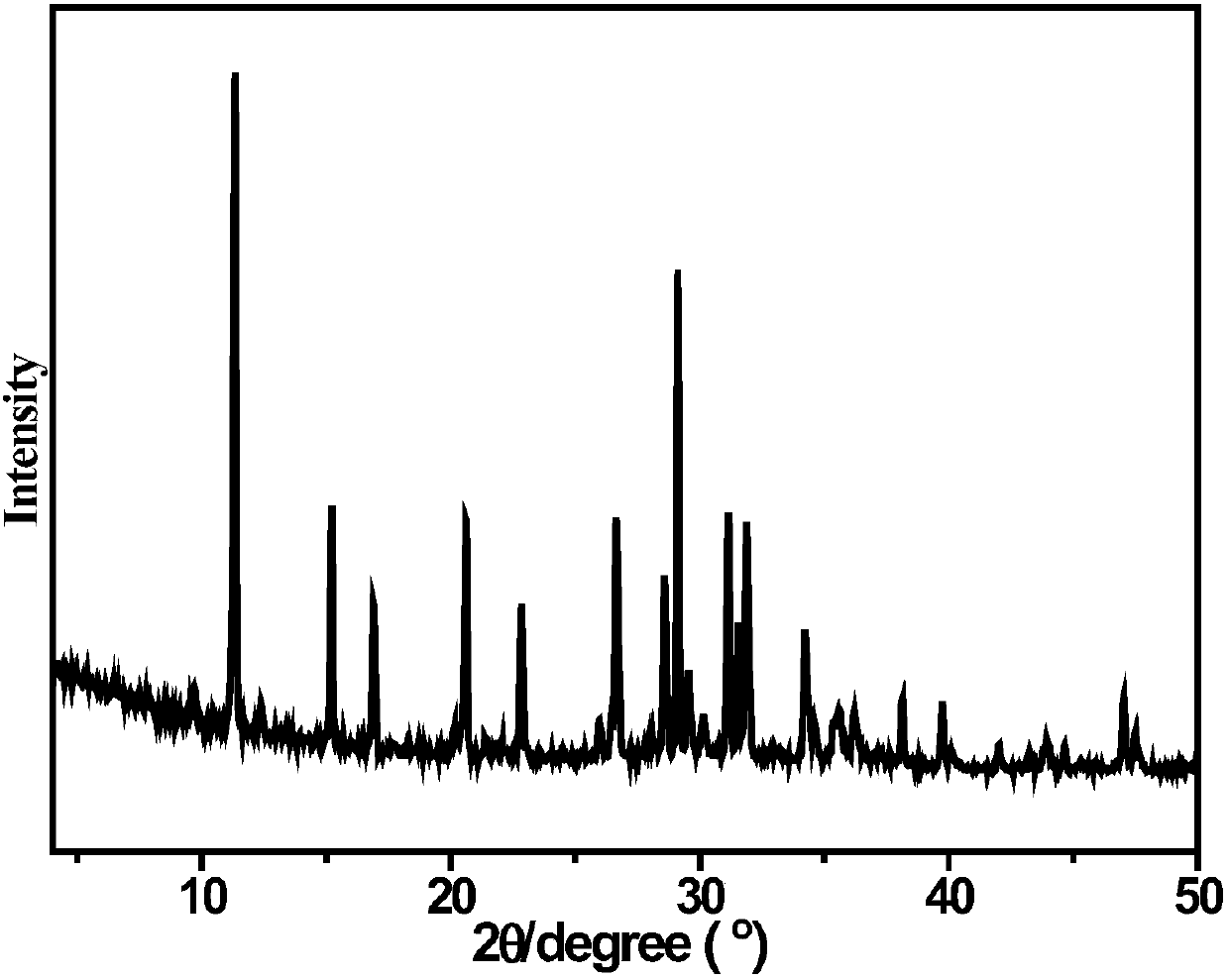

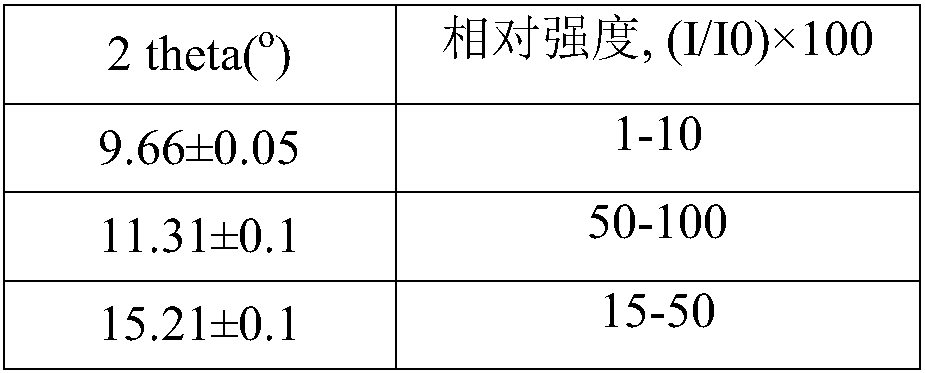

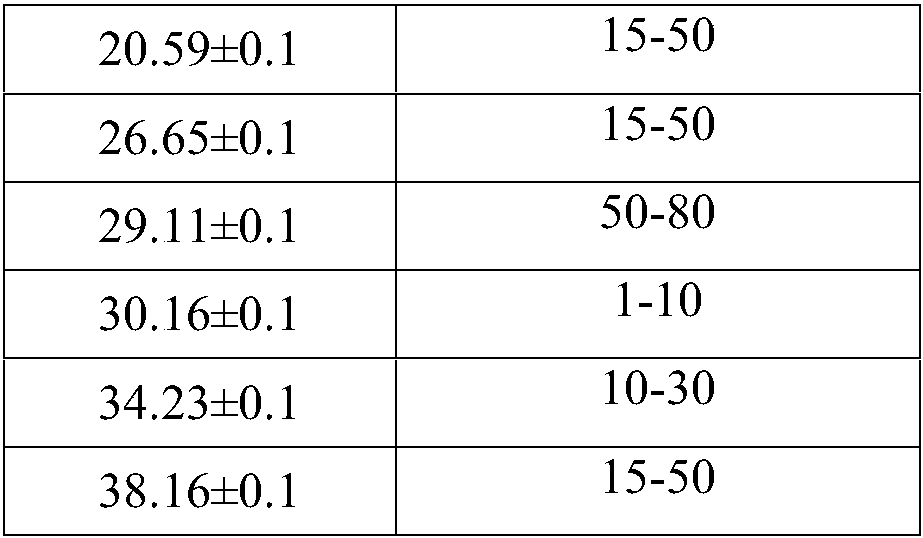

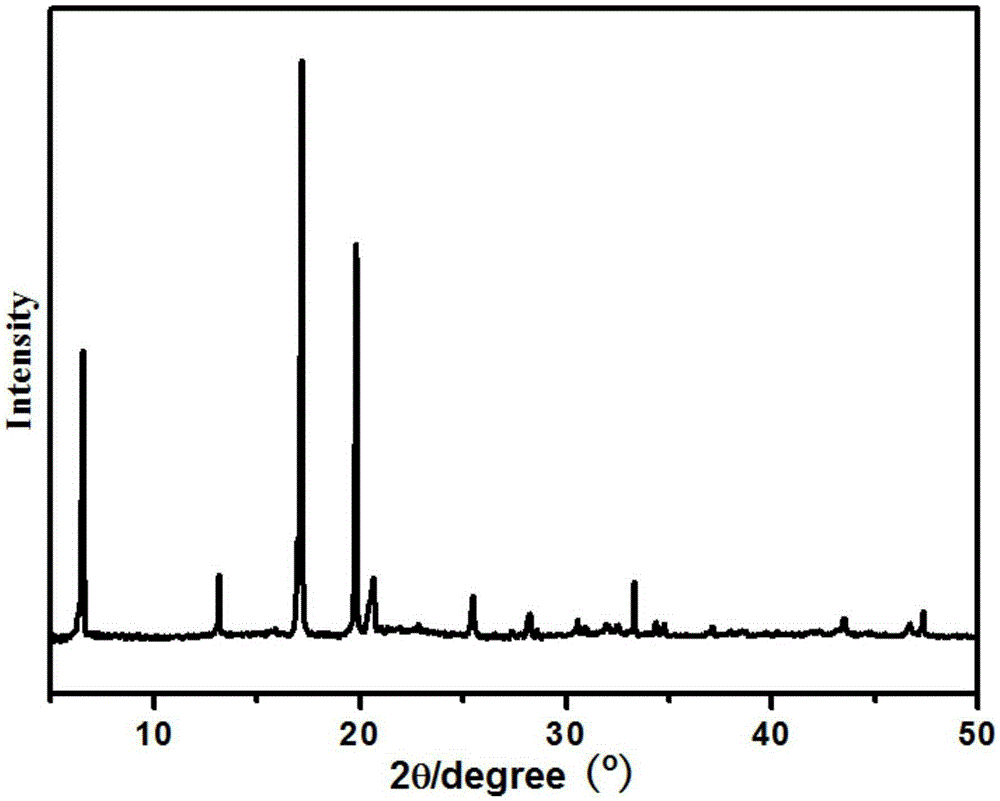

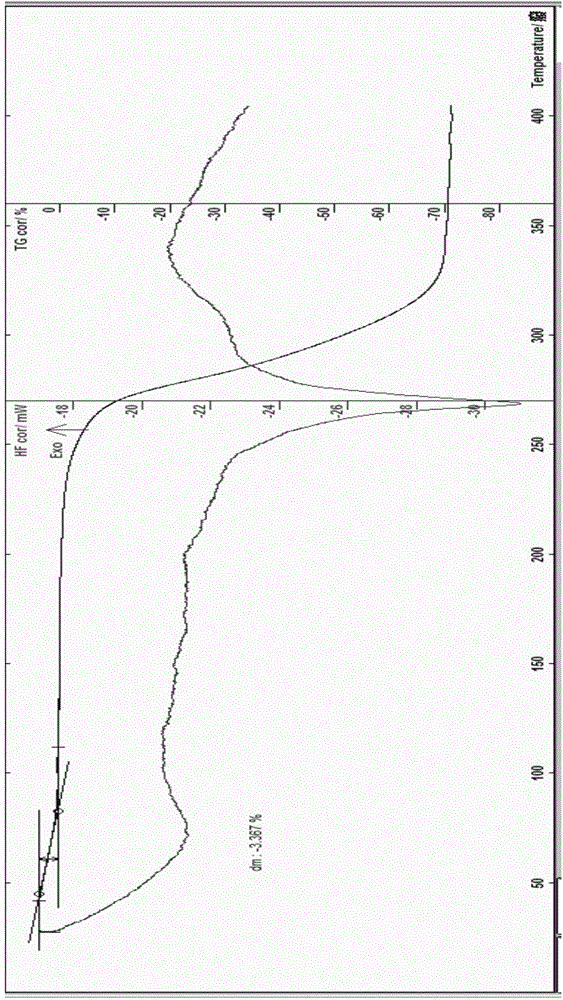

SCM-12 molecular sieve and preparation method thereof

ActiveCN107777701AHigh crystallinityThe skeleton structure is thermally stableMolecular sieve catalystsMolecular sieve catalystManganeseX-ray

The invention relates to an SCM-12 molecular sieve and a preparation method thereof, mainly aiming at solving the technical problems of an SCM-12 molecular sieve with a novel structure which is not related in the prior art. The invention provides a novel SCM-12 molecular sieve with an open framework structure. The SCM-12 molecular sieve is prepared from the following chemical components accordingto the following mol ratio: x(XO) to y(Y2O3): z(Z2O5), wherein X is at least one of elements including manganese, magnesium, nickel, copper, zinc and the like; Y is at least one of elements includingaluminum, boron, gallium and the like; Z is a phosphorus element; x is greater than or equal to 0.01 and less than or equal to 100; y is greater than or equal to 0.01 and less than or equal to 100; zis greater than or equal to 0.01 and less than or equal to 100; an XRD (X-Ray Diffraction) pattern of the SCM-12 molecular sieve has diffraction peaks when 2theta is equal to 9.66+ / -0.05, 11.31+ / -0.1,15.21+ / -0.1, 20.59+ / -0.1, 26.65+ / -0.1, 29.11+ / -0.1, 34.23+ / -0.1 and 38.16+ / -0.1; by adopting the technical scheme, the technical problems are solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method capable of preventing abalone soup cans from blackening

ActiveCN102150894APrevent oxidative browningEffective complexationFood preparationEngineeringProcess engineering

The invention discloses a processing method capable of preventing abalone soup cans from blackening. The method comprises the following steps: timely performing anti-blackening color protection process treatment for three times during fishing of abalone, workshop pretreatment and pre-boiling and soup-loading process, and then performing sterilization and storage. Through the three times of timely continuous anti-oxidation and anti-blackening color protection treatment with seamless oxygen contact, the original color, luster and quality of products can be effectively kept.

Owner:福州日兴水产食品有限公司

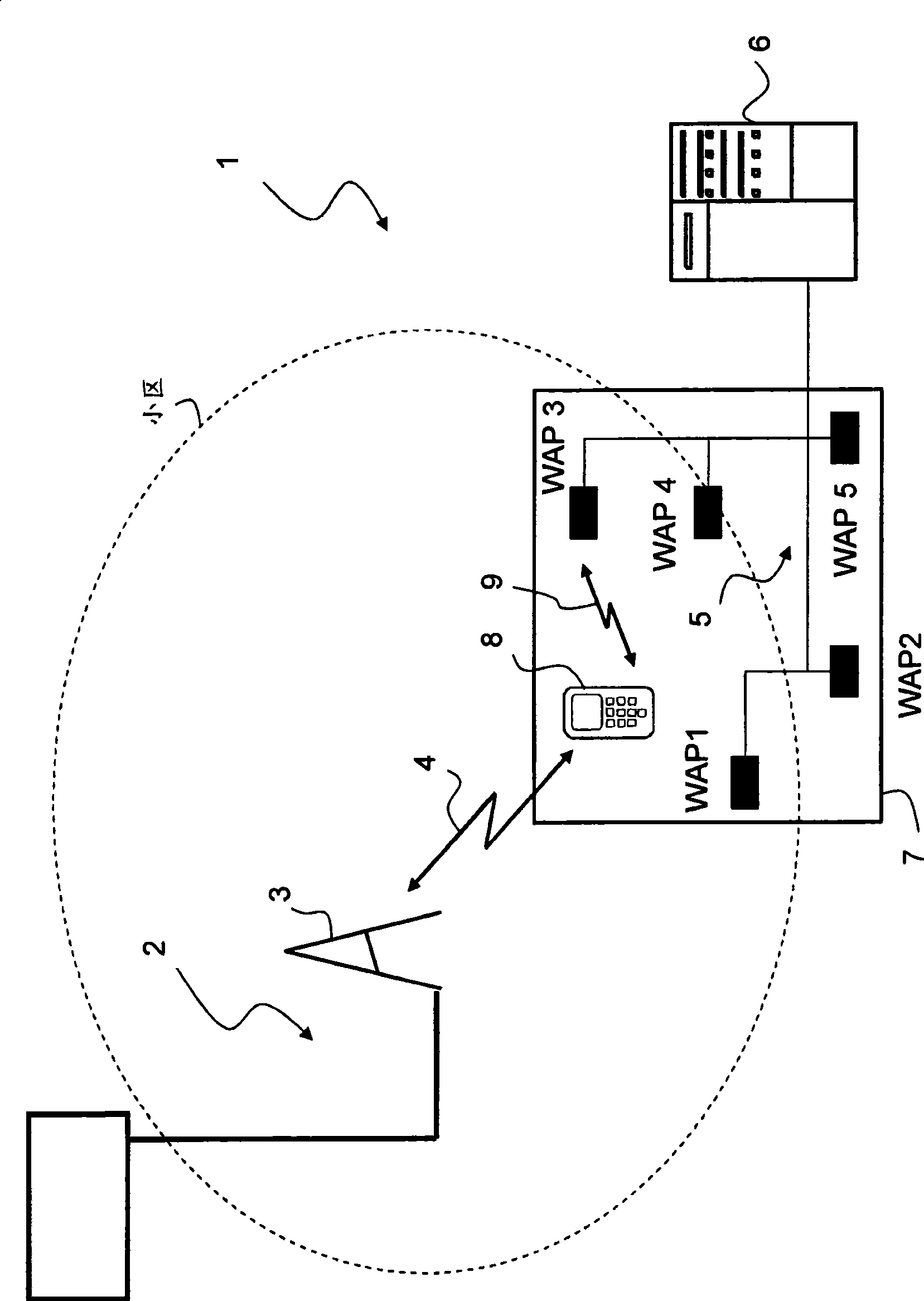

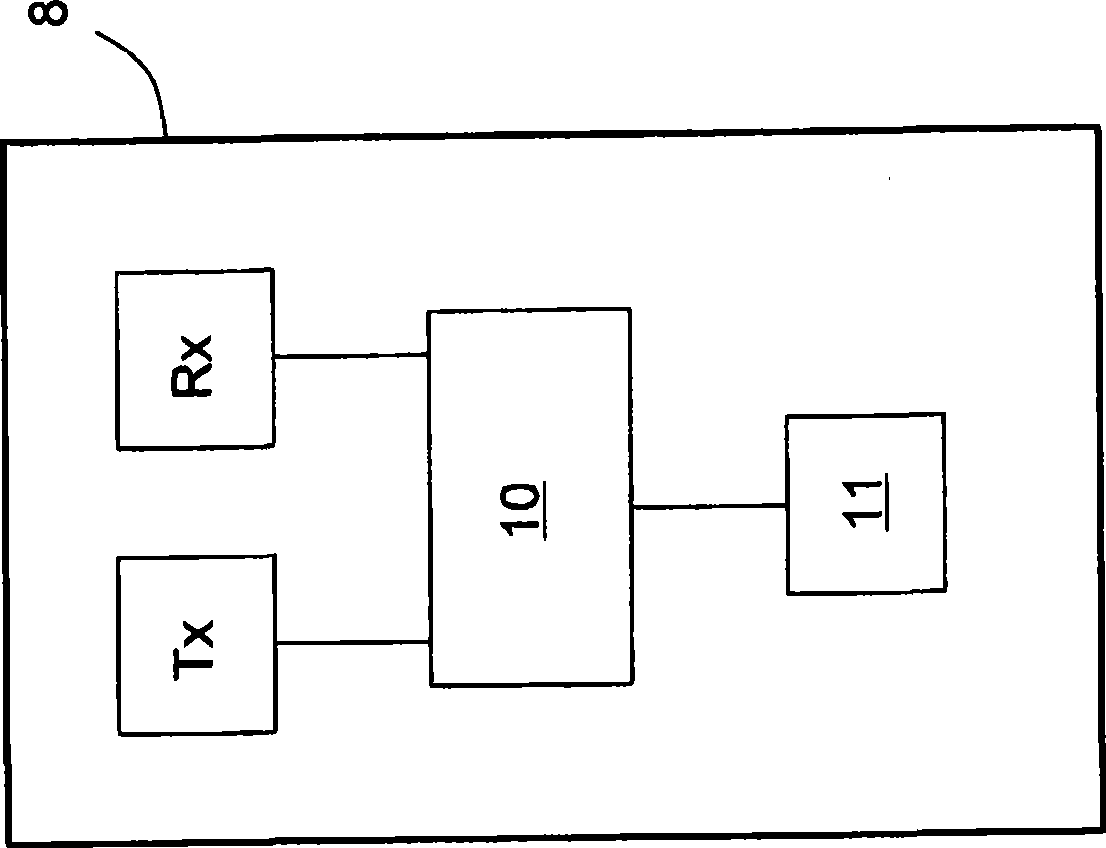

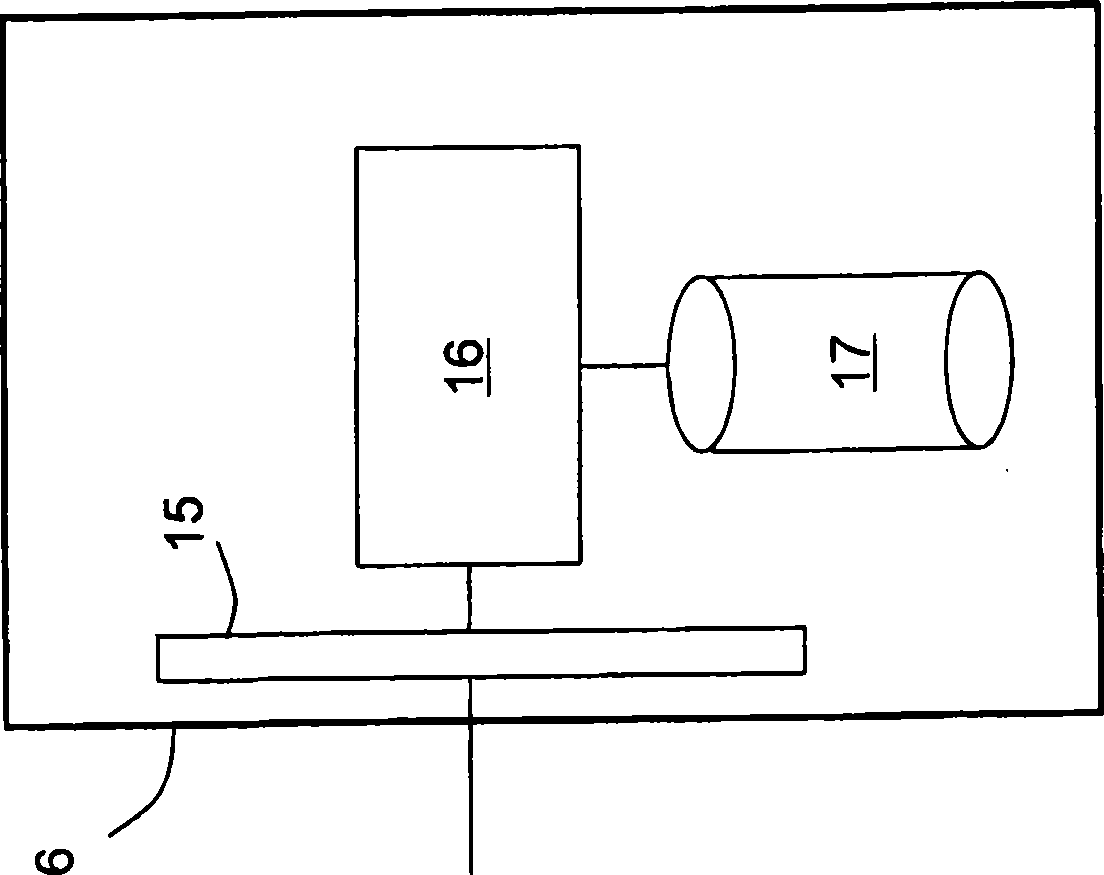

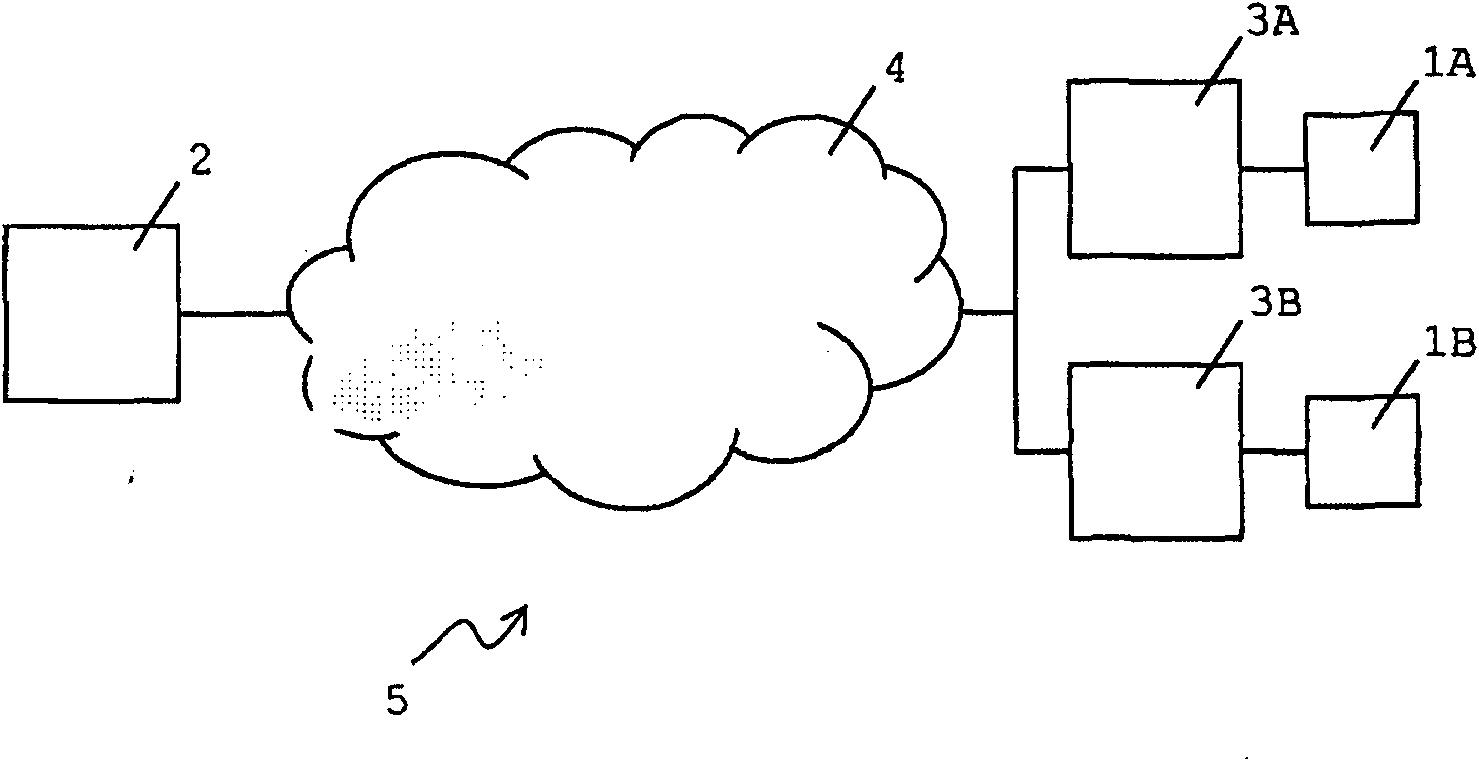

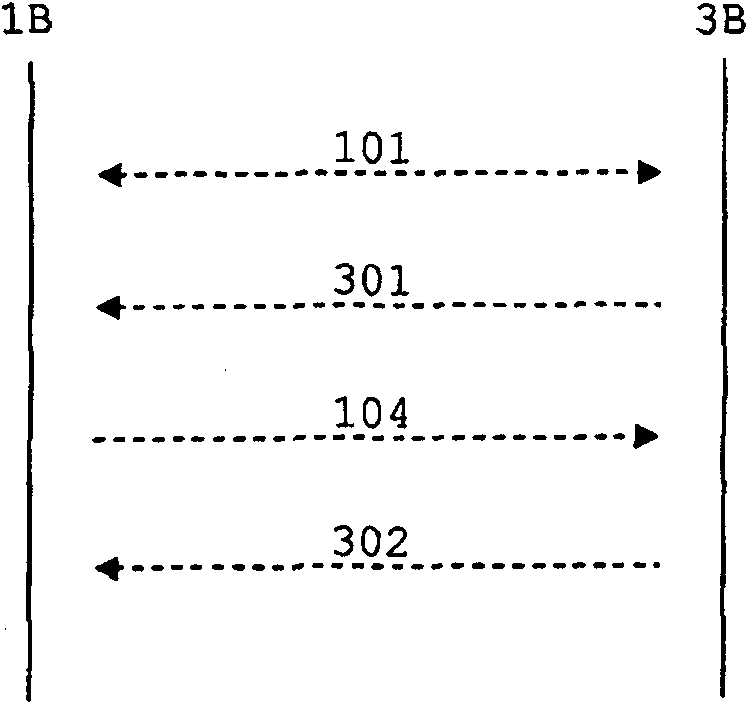

Emergency system and method

ActiveCN101466085AImprove reliabilitySave radio resourcesEmergency connection handlingConnection managementBroadcast channelsTelecommunications network

The invention relates to a system and a method of receiving local emergency information on a mobile device in a system comprising a telecommunication network and at least one local communication network comprising one or more wireless access points. The mobile device receives a general emergency signal over a broadcast channel of the telecommunication network. In response to the general emergency signal, the mobile device connects to one of the wireless access points and transmits a request for transmitting the local emergency information to the mobile device. The mobile device then receives the local emergency information from one of said wireless access points.

Owner:KONINK KPN NV +1

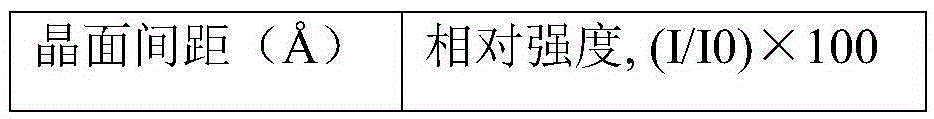

SCM-9 molecular sieve and preparation method thereof

ActiveCN106830004AImprove stabilityGood hydrothermal stabilityMolecular-sieve and base-exchange compoundsMolecular sieveChemical composition

The present invention relates to a kind of SCM-9 molecular sieve and preparation method thereof, mainly solve the technical problem of molecular sieve SCM-9 of new structure not involved in the prior art, the present invention provides a kind of new SCM-9 molecular sieve, by adopting and comprising the following Chemical composition in molar ratio: XO 2 :nY 2 o 3 , 0.002≤n≤0.25, the technical scheme in which the XRD diffraction pattern of the SCM-9 molecular sieve has diffraction peaks at 2θ of 6.56±0.05, 13.18±0.1, 19.83±0.1, 25.48±0.1, and 30.57±0.1 is better The above-mentioned technical problems are solved, and the molecular sieve can be used in the industrial production of methanol to olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

Signcryption scheme based on elliptic curve cryptography

InactiveCN101645773AReduce overheadLimit the scope of protectionPublic key for secure communicationUser identity/authority verificationDigital signatureEnd system

The invention provides a method and a system for signcrypting data based on elliptic curve cryptography. In a head-end system, data is encrypted using a random point R and digitally signed using the random point R. Only the x-coordinate R x of the random point R and only the signature components signature of the signature are added to the data after signcrypting the data. In a smartcard the signcrypted data is verified using the random point R and decrypted using the random point R.

Owner:IRDETO BV

Rubber type pressure-sensitive adhesive for surface protection film and preparation method thereof

The invention discloses a rubber-type pressure-sensitive adhesive applied to a surface protective film and a preparation method thereof. The rubber-type pressure-sensitive adhesive is prepared by blend refining, thin passing and sheeting natural rubber, an anti-aging agent BHT, a compounding agent, partial tackifying resin and partial vulcanizing agent and a rubber compound is obtained therefrom; at room temperature, a gasoline-ethyl acetate mixed solvent is added into an anti-explosion static-free stirring container; then the rubber compound, remained tackifying resin and vulcanizing agent are added; the container is closed; after even stirring and blending, the remained vulcanizing agent is added; and stirring and filtering are carried out again so as to obtain the rubber-type pressure-sensitive adhesive applied to the surface protective film. The rubber-type pressure-sensitive adhesive applied to the surface protective film can obtain appropriate initial adhesive performance, anti-stripping performance and anti-creeping performance by adjusting the usage of the vulcanizing agent and the adhesive, thereby realizing the balance among the three performances and overcoming the problems of bad keying strength and anti-aging performance and the like of a rubber-type pressure-sensitive adhesive.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

Compound filling for sewage treatment

InactiveCN1699214AHigh mechanical strengthImprove impact resistanceSustainable biological treatmentBiological water/sewage treatmentPorosityAdhesive

The invention discloses a compound filling for sewage treatment which comprises the components (by weight portion) of medical stone 3-12, lump lime 2-18, industrial adhesives 1-3, or pore-forming agent 1-3. The invention also discloses the process for preparing the compounded mixture, which has the advantages of small volume weight, large high specific surface area, high degree of porosity, and impact load proofing.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

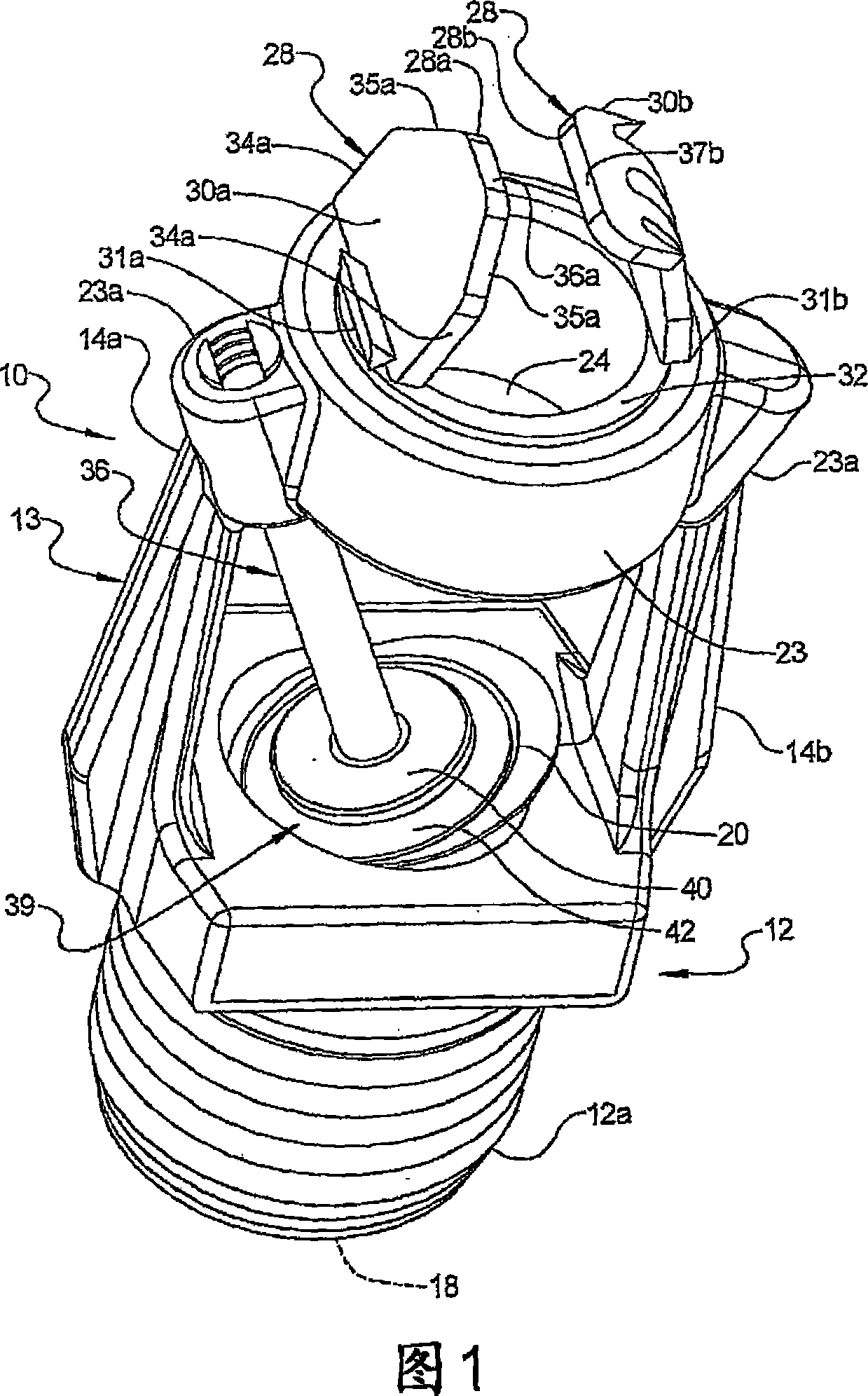

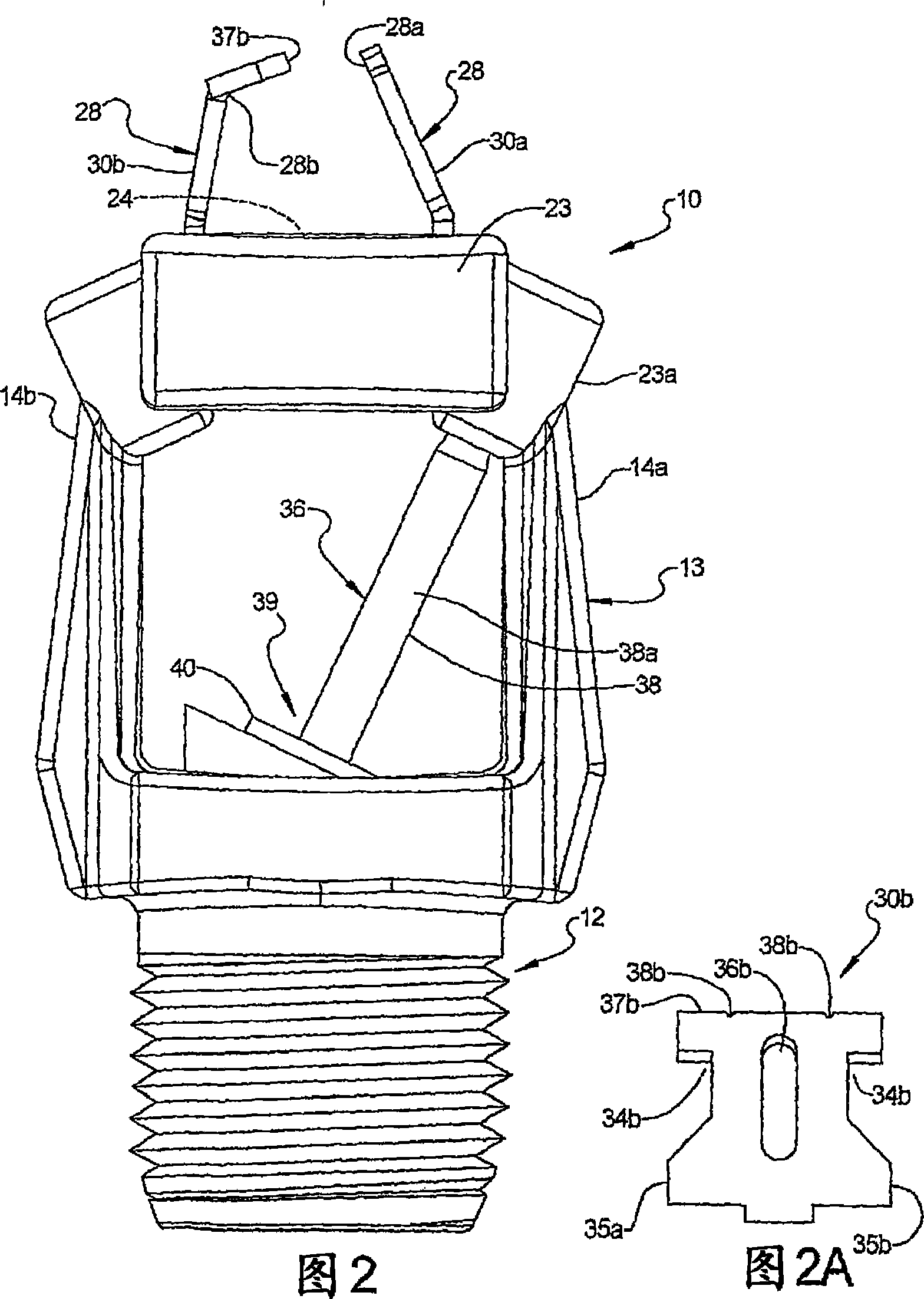

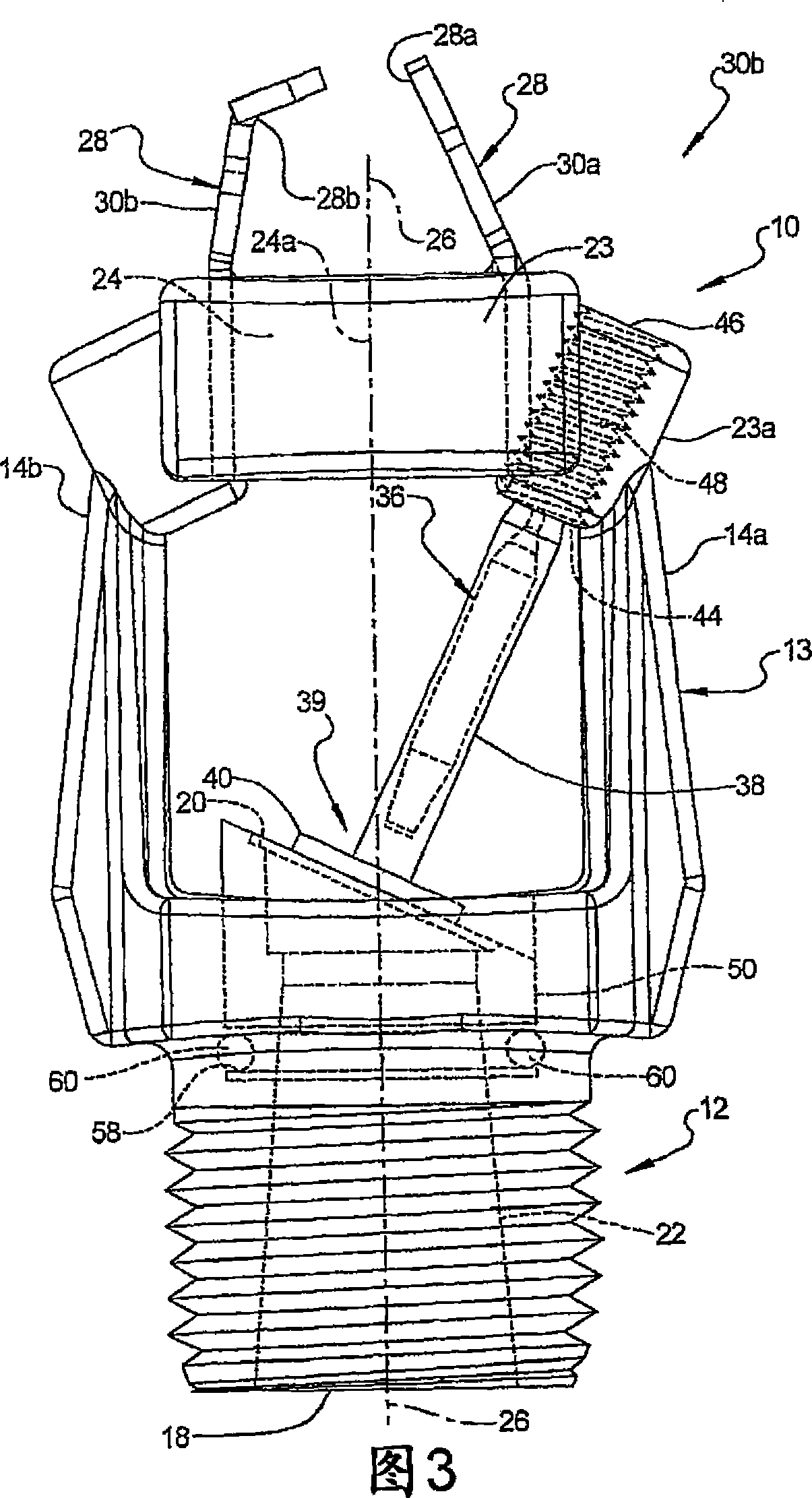

Sprinkler assembly

ActiveCN101184554AReduce energy consumptionReduce lossesSpray nozzlesFire rescueSprinkler systemEngineering

A sprinkler assembly includes a body, a support, which extends from the body, and a closure device that releasably closes the discharge opening of the body. The sprinkler assembly further includes a trigger that releasably holds the closure device at the discharge opening. The support is adapted to allow the fluid flowing from the discharge opening, when the closure device is released, to pass through the support substantially unimpeded by the support and, further, is adapted to reshape the flow of fluid as it flows through the support.

Owner:VIKING

Solvent systems of n-alkyl thiophosphoric triamides and methods of use in agricultural applications

ActiveCN104136398ALimit the scope of protectionOrganic compound preparationGroup 5/15 element organic compoundsUrocaninaseUrease Inhibitors

Owner:RHODIA OPERATIONS SAS +1

Erasable ink and preparation method thereof

The invention discloses erasable ink and preparation method thereof, the ink does not block a pen head, is easy to wipe the ink marks and has better color effect and green environment protection. The ink comprises the following components in percentage by weight: 50 percent-60 percent of micrometer-grade coloring microsphere, 0.5 percent-1 percent of antibacterial agent, 0.3 percent-1 percent of thickening agent and the balance of common tap water or de-ionized water, wherein the micrometer-grade coloring microsphere consists of polymethylmethacrylate or butyl methacrylate coated with pigment or dye, and the grain diameter is between 1 micrometer and 10 micrometers. The ink is better to write and easier to wipe than the pencil without marks, and has the advantages of smooth writing, uniform ink flow, dense and bright color of the ink marks, long time for unbonneting, no pollution and environment protection, waterproof and sunproof written marks and long preservation time and the like.

Owner:刘海生

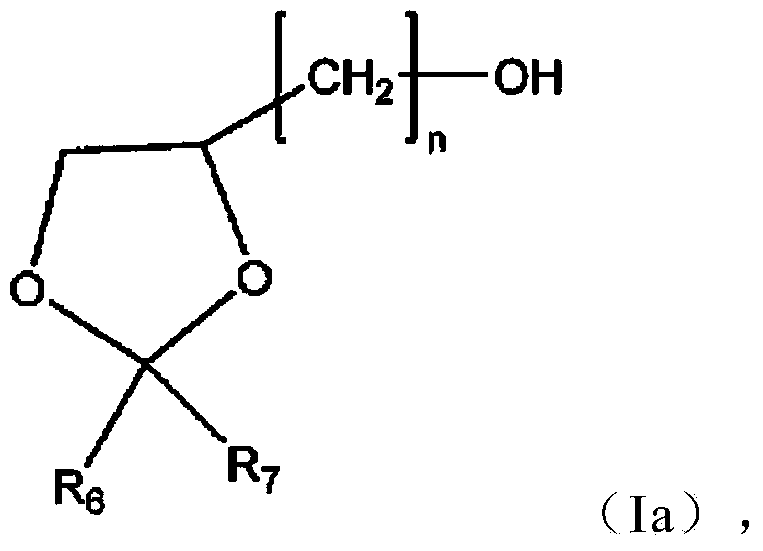

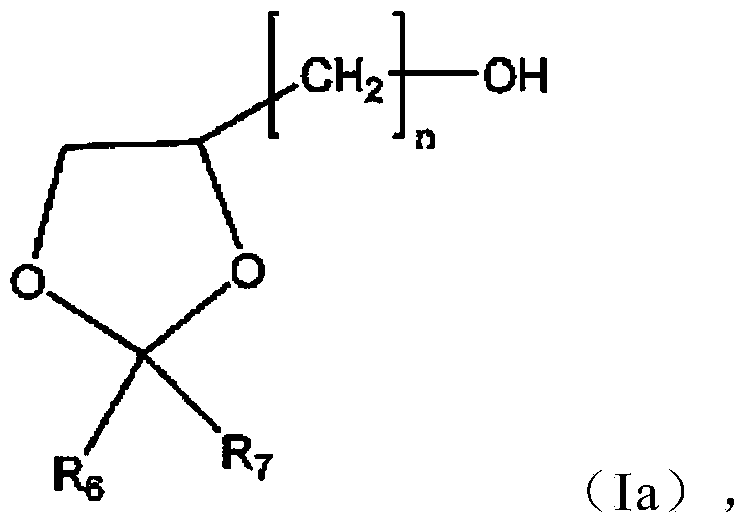

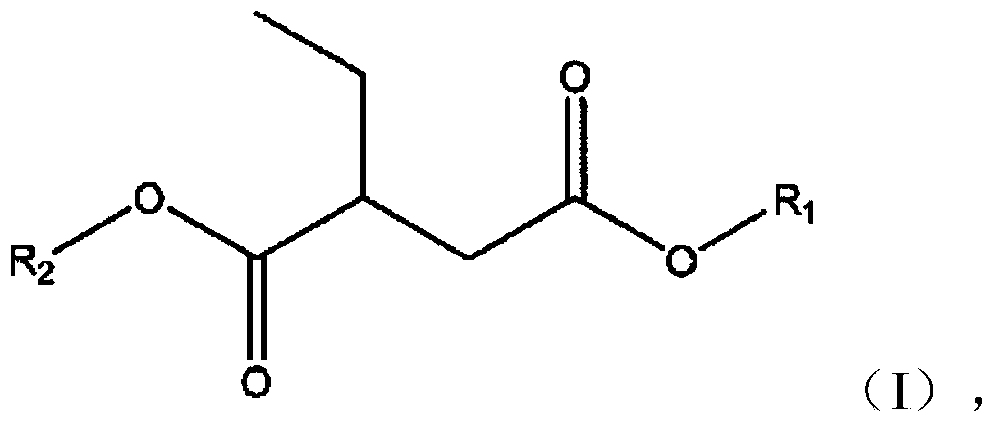

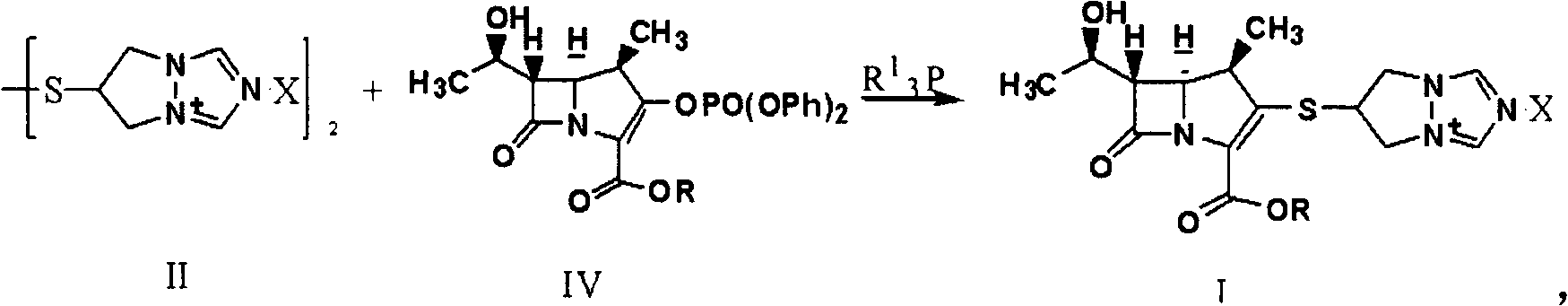

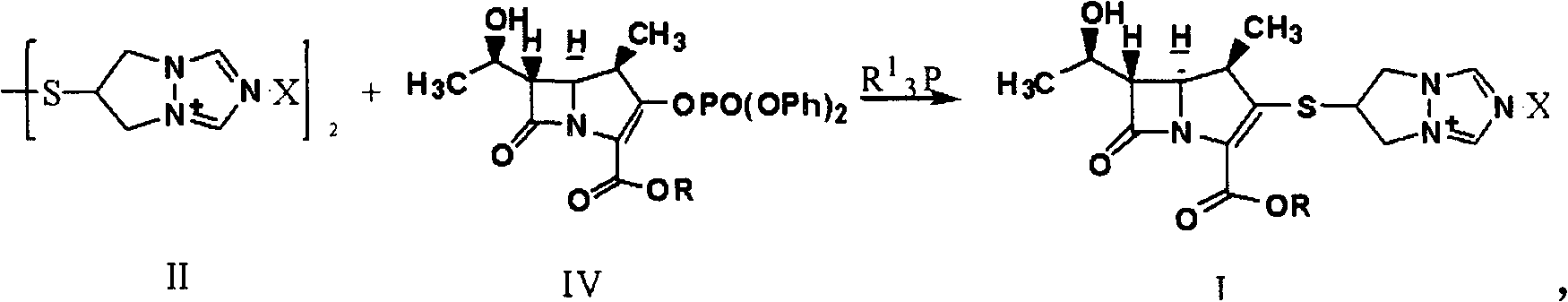

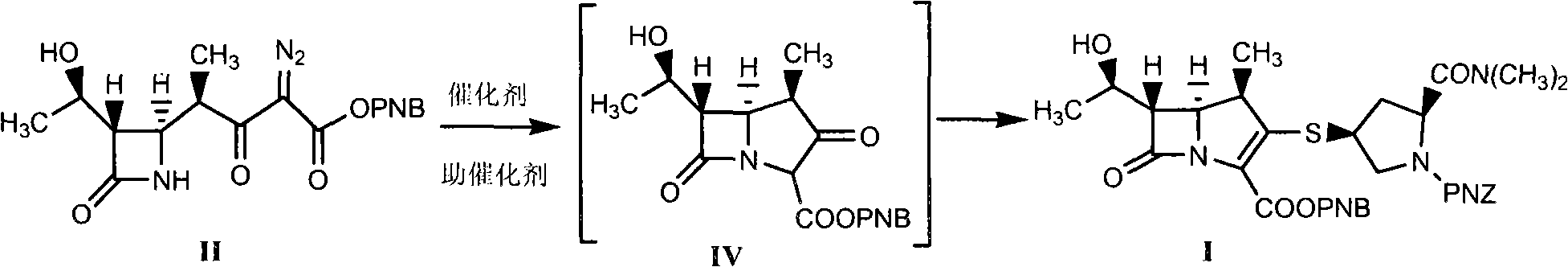

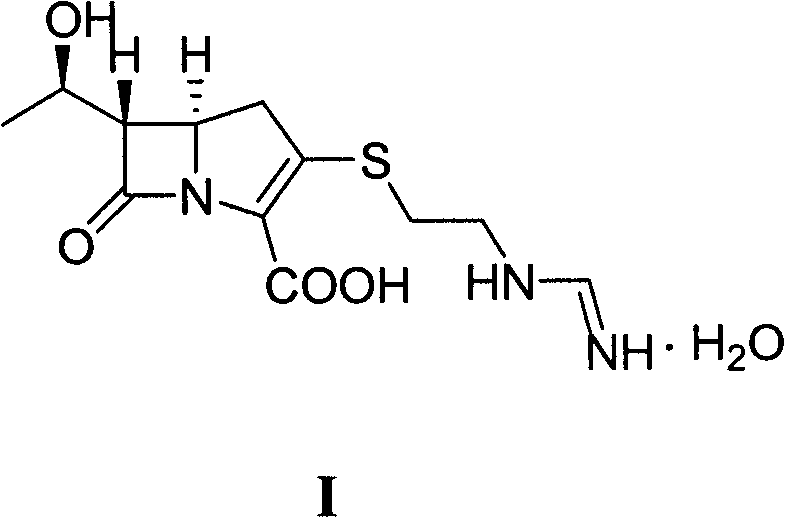

Synthesis method of biapenem ester

ActiveCN101891756ASimple and fast operationEasy to manufactureOrganic chemistryOrganic solventSynthesis methods

The invention relates to a synthesis method of biapenem ester, which comprises the steps of: 1) under the condition of air isolation, adding organic solvent, compound (II), compound (IV), R13P and alkali into a reactor, controlling the reaction temperature, and reacting for more than 15min; 2) carrying out HPLC monitoring, and using acid to adjust a system to acidity after reaction; and 3) crystallizing, cooling the reaction liquid, adding crystallization solvent for stirring and crystallization, filtering and obtaining the target compound (compound I). The invention has simple and convenient operation, can directly crystallize without needing purification in the reaction, and avoids using biapenem branched chain which is compound (III) and is easy in moisture absorption and difficult to prepare and store.

Owner:SHENZHEN HAIBIN PHARMA

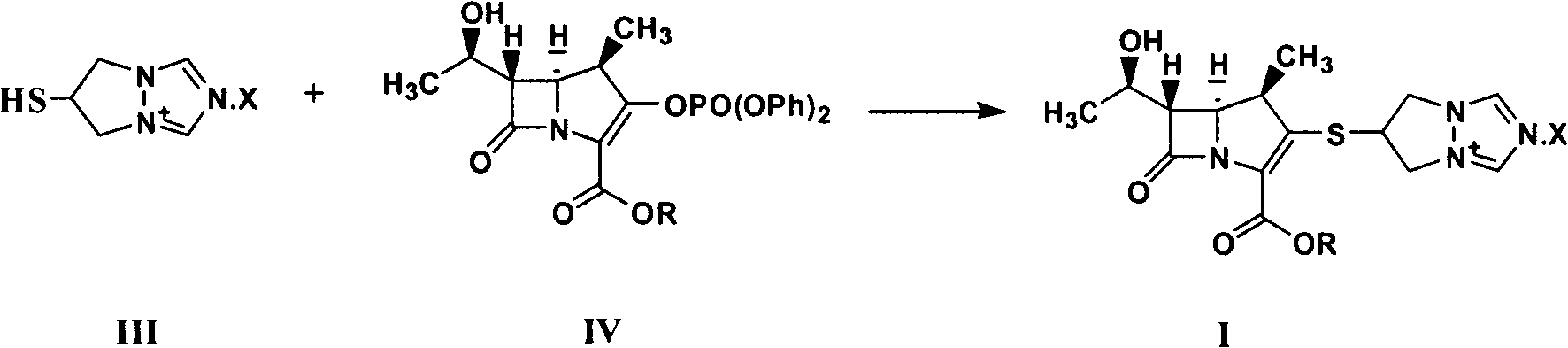

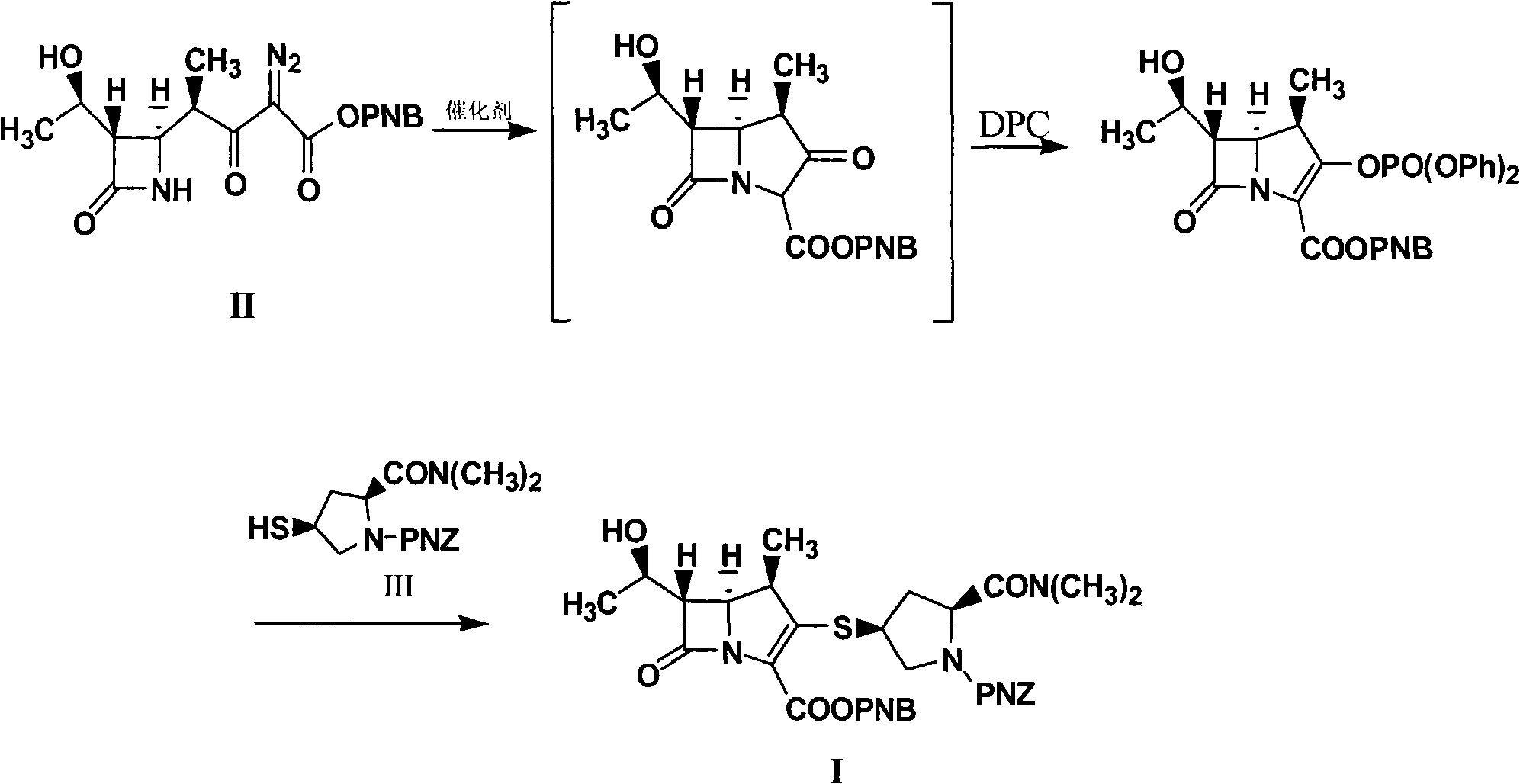

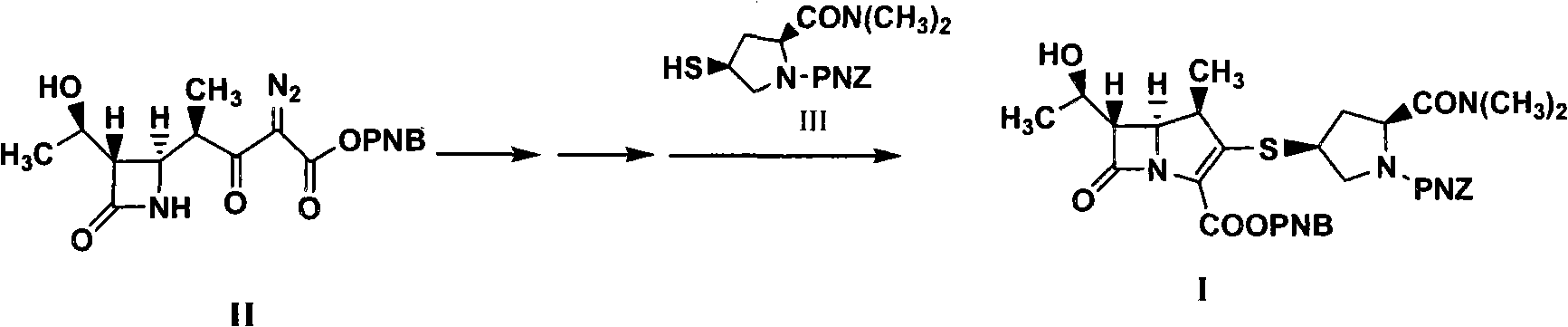

Method for synthesizing meropenem intermediate

The invention relates to a method for synthesizing a meropenem intermediate, which comprises the following steps: (1) in an inert gas atmosphere, adding an organic solvent, a compound II, a noble metal catalyst and auxiliary catalysts into a reactor, heating the materials to perform a reaction, and monitoring the reaction by TLC or HPLC; (2) at the end of the reaction, adding the organic solvent, cooling the reaction solution, adding an organic alkali or DPC, and monitoring a reaction by the TLC or HPLC; (3) at the end of the reaction, cooling the reaction solution, adding the organic alkali and a compound III, performing a reaction at a controlled temperature, and monitoring the reaction by the TLC or HPLC; and (4) washing, removing a water phase, dehydrating an organic phase, filtering to remove solid, concentrating the organic phase, adding the organic solvent for crystallization, filtering the solution, washing the crystals, and drying the crystals to obtain the target compound I. Compared with the techniques of the same kind, the method, which is simple and convenient in operation, of the invention has the advantages of adding two auxiliary catalysts at the same time, greatly reducing the consumption of noble metal catalyst, making raw materials react more completely, producing less impurities and improving product yield.

Owner:XINXIANG HAIBIN PHARMA

Preparation method of asenapine intermediate

Owner:SHANGHAI HAOYUAN MEDCHEMEXPRESS CO LTD

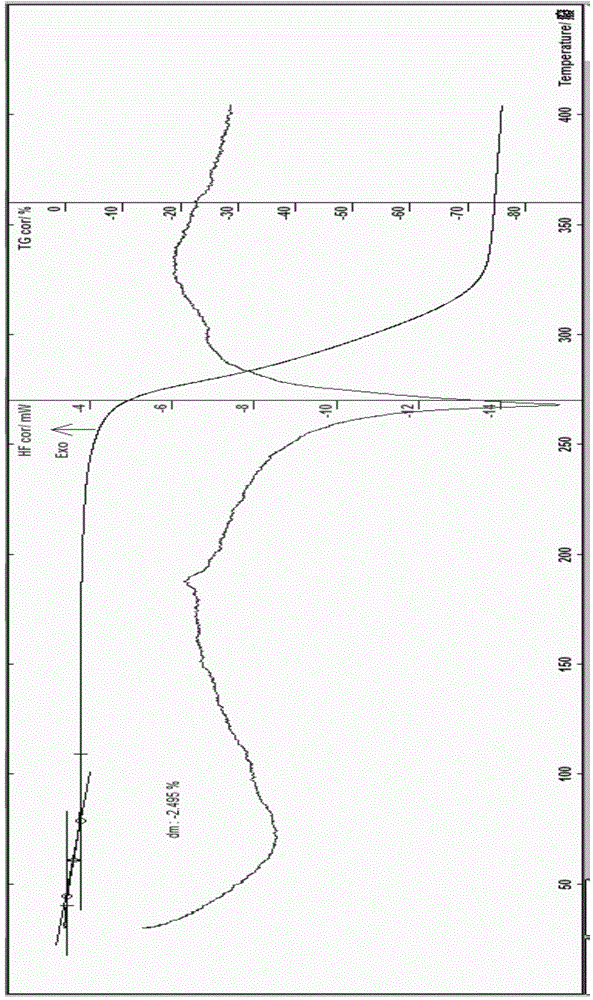

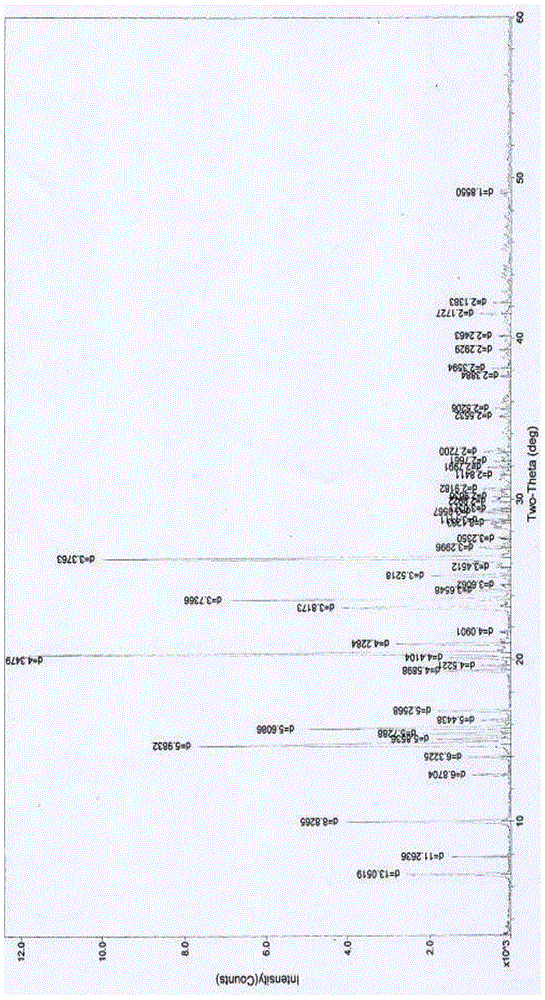

Method for preparing imipenem monohydrate crystal

The invention relates to a method for preparing an imipenem monohydrate crystal (I), which comprises the following steps of: 1) dissolving the crude product of imipenem in water in the nitrogen atmosphere to obtain solution; 2) performing activated carbon treatment on the solution; 3) adding an organic solvent into the solution and reducing the temperature to make the solution in a solid-liquid mixed state so as to form a crystal nucleus; and 4) raising the temperature to melt the crystal nucleus and adding the organic solvent to crystallize and precipitate imipenem monohydrate so as to obtain the imipenem monohydrate crystal. The method for preparing the imipenem monohydrate crystal does not comprise the step of thickening and dewatering or adding acid or alkali to adjust the pH value, so the method is simpler and effective and is easy to control; and the imipenem monohydrate crystal prepared by the method has the advantages of uniform crystallinity, high purity and quick solubility.

Owner:SHENZHEN HAIBIN PHARMA +1

Dibenzo quinolizine compound entity and application thereof

InactiveCN105566316AReduce humidityEasy to slideOrganic active ingredientsNervous disorderReperfusion injuryQuinolizine

Dibenzo quinolizine compound entity has relatively low hygroscopicity and relatively high storage stability, and is applicable to preparation of analgesic, sedative, hypnotic and tranquillizing medicines, medicines for treating hypertension, arrhythmia and functional dyspepsia, stopping cough, resisting schizophrenia and heroin and other drug dependence, reversing tumor cell drug resistance and delaying or reducing myocardial ischemia reperfusion injury, calcium antagonists, and medicines for protecting the liver and preventing visceral implicated reaction and other effects, which are applied to humans or animals.

Owner:刘力

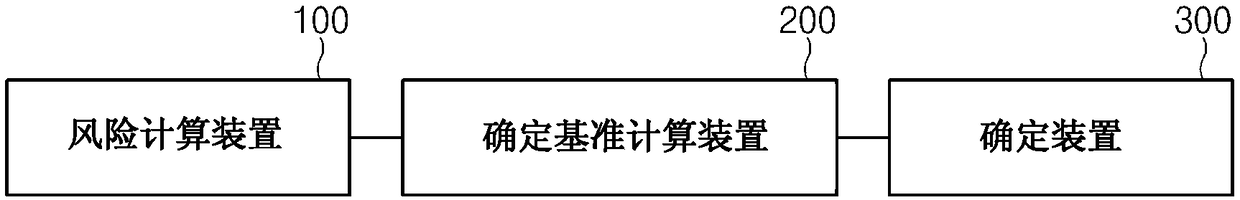

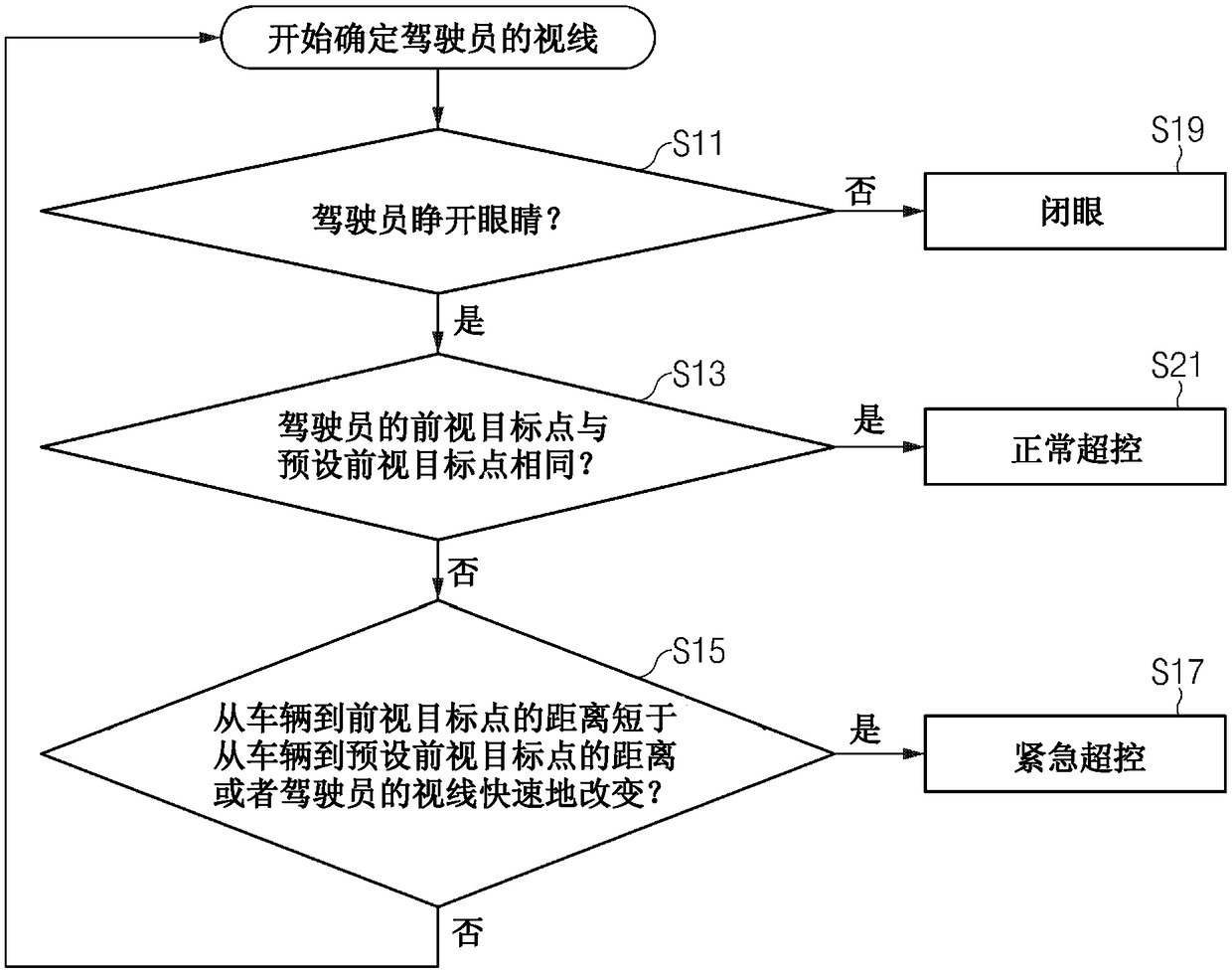

System and method for determining transfer of driving control authority of self-driving vehicle

ActiveCN108202742AFree transferNot intended to limit the scope of protectionVehicle position/course/altitude controlDriver input parametersSteering wheelEngineering

Disclosed is a system for determining transfer of driving control authority of a self-driving vehicle. The system includes: a risk calculation device that recognizes a sight line of a driver to calculate a risk when the driving control authority of the self-driving vehicle is transferred, a determination reference calculation device that calculates a determination reference to determine whether the driving control authority of an acceleration pedal, a deceleration pedal, and a steering wheel of the self-driving vehicle is able to be transferred based on the calculated risk, and a determinationdevice that determines whether to transfer the driving control authority of the self-driving vehicle based on the calculated determination reference.

Owner:HYUNDAI MOTOR CO LTD +1

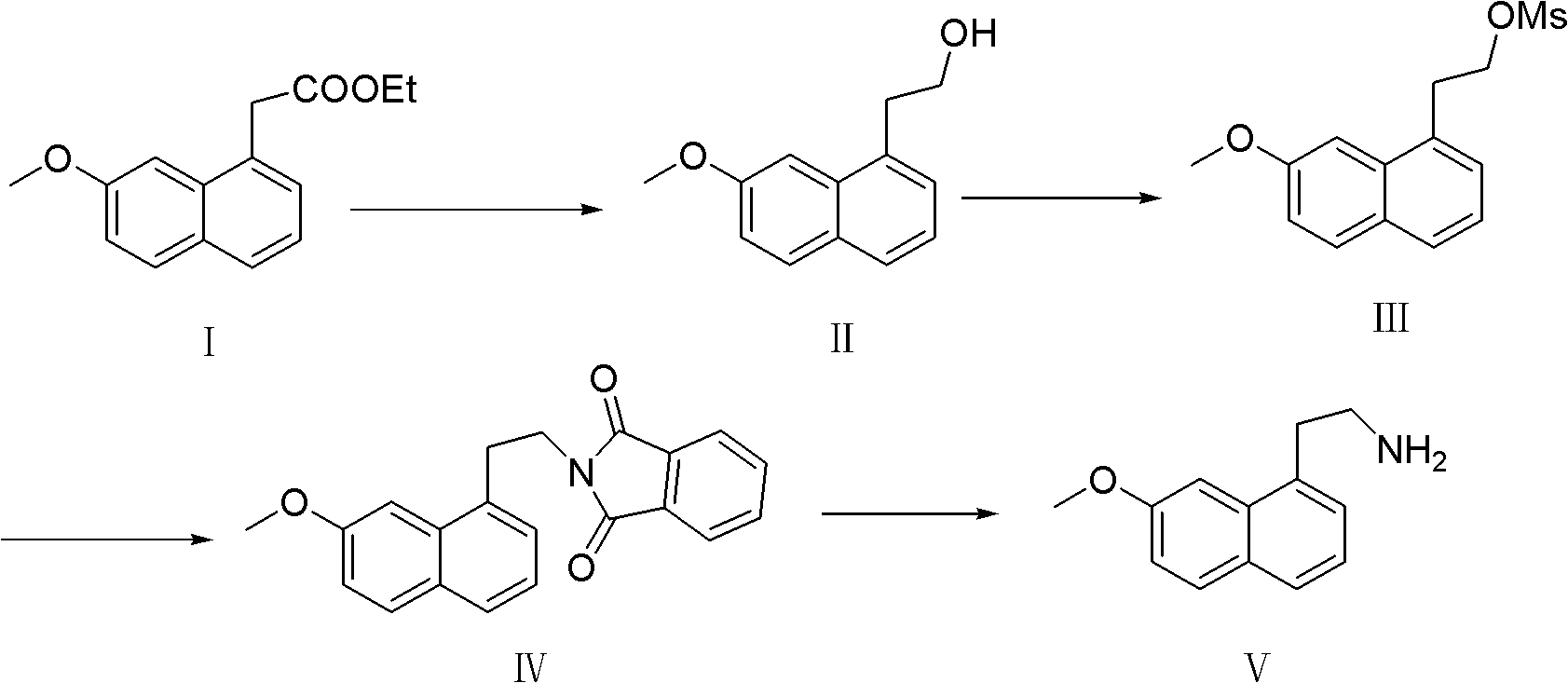

Preparation method of 7-methoxy-1-naphthylethylamine

InactiveCN102603545ALow costReduce usageOrganic compound preparationAmino-hyroxy compound preparationAcetic acidSodium borohydride

The invention belongs to the technical field of pharmaceutical intermediates, and in particular relates to a new preparation method of a key intermediate, 7-methoxy-1-naphthylethylamine of a pharmaceutical ingredient, agomelatine. The aim of the invention is to reduce the cost, optimize the process and bring convenience to the industrial production. The preparation method comprises the following steps: taking 7-methoxy-1-naphthylacetate as a raw material; reducing by sodium borohydride to obtain 7-methoxy-1-naphthaleneethanol; carrying out a methyl sulfonylation reaction to obtain 7-methoxy-1-naphthylethylmethanesulfonate; reacting 7-methoxy-1-naphthylethylmethanesulfonate with a phthalimide potassium salt to obtain 7-methoxy-1-(N-phthalimidoethyl)naphthyl; and finally hydrolyzing 7-methoxy-1-(N-phthalimidoethyl)naphthyl to obtain the product, 7-methoxy-1-naphthylethylamine. The preparation method has the advantages of being simple and convenient in operation, reasonable in reaction process, low in production cost, good in product quality, high in purity (above 98%), having no environment pollution and being suitable for industrial production.

Owner:湖北万知化工医药股份有限公司

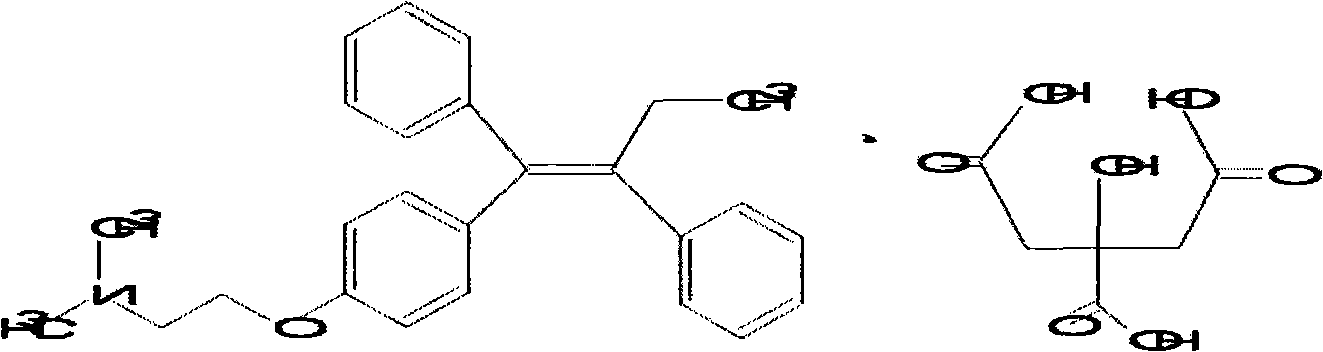

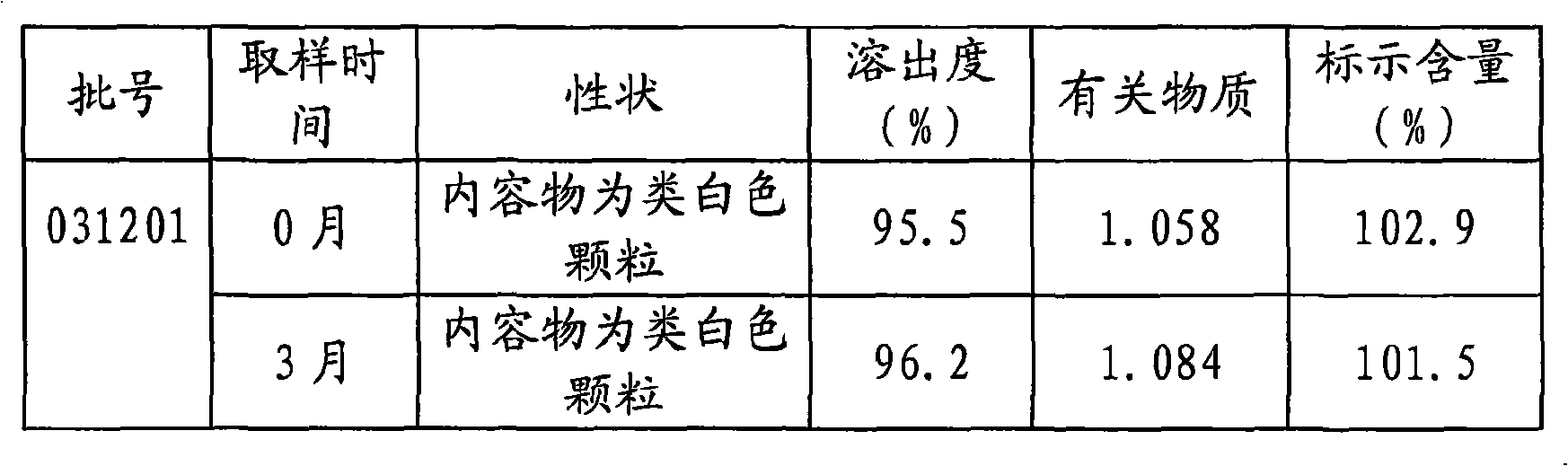

Acidum citricum nolvadex capsule and preparation method thereof

InactiveCN101269050AEasy to manufactureLow costOrganic active ingredientsPharmaceutical non-active ingredientsMagnesium stearateCitric acid

The invention discloses a citric acid tamoxifen capsule and consists of 5 to 25 percent of citric acid tamoxifen, 35 to 55 percent of starch, 35 to 50 percent of microcrystalline cellulose, 2 to 5 percent of PVPP and 0.2 to 0.5 percent of magnesium stearate according to the weight percentage.

Owner:孙向阳

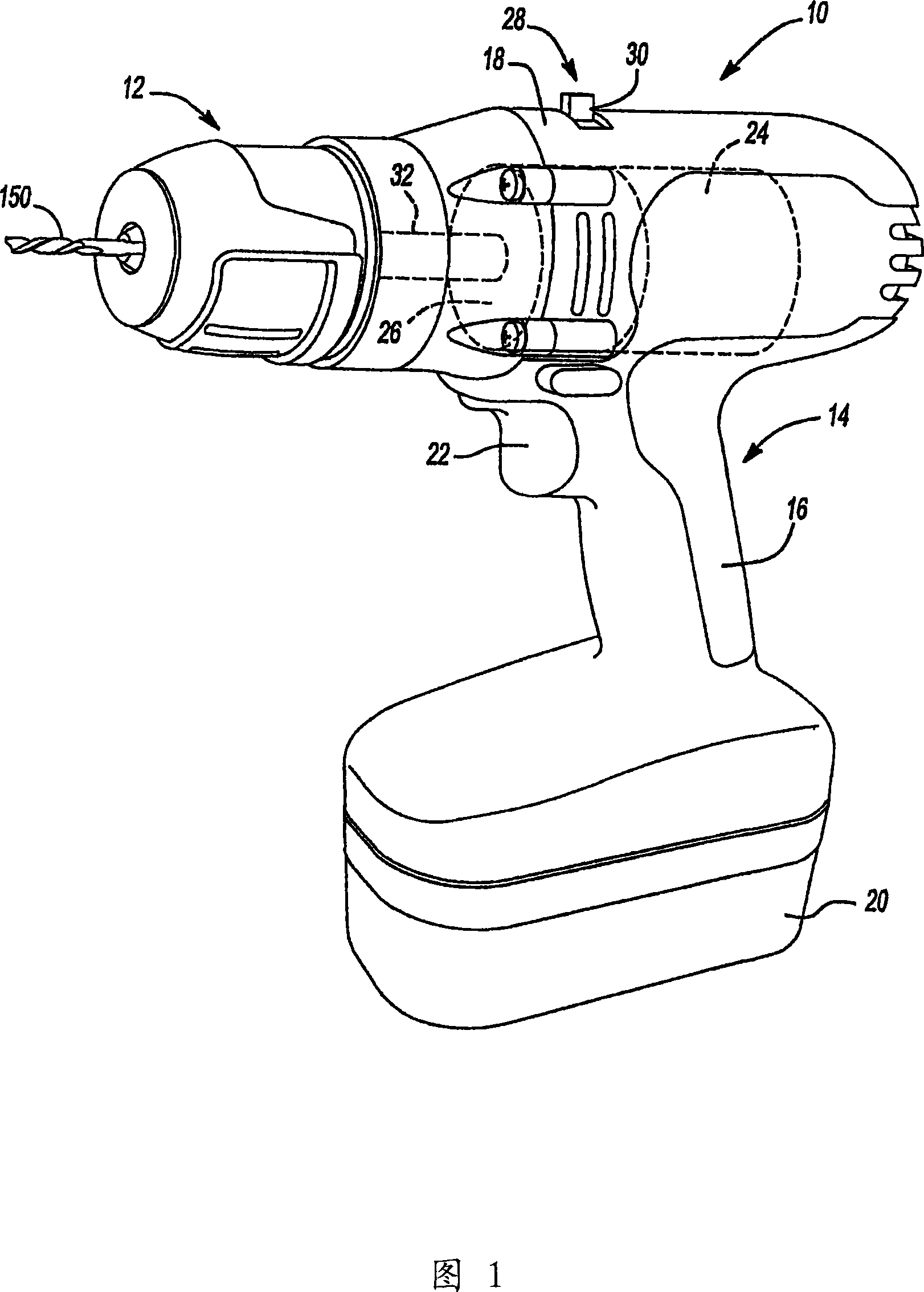

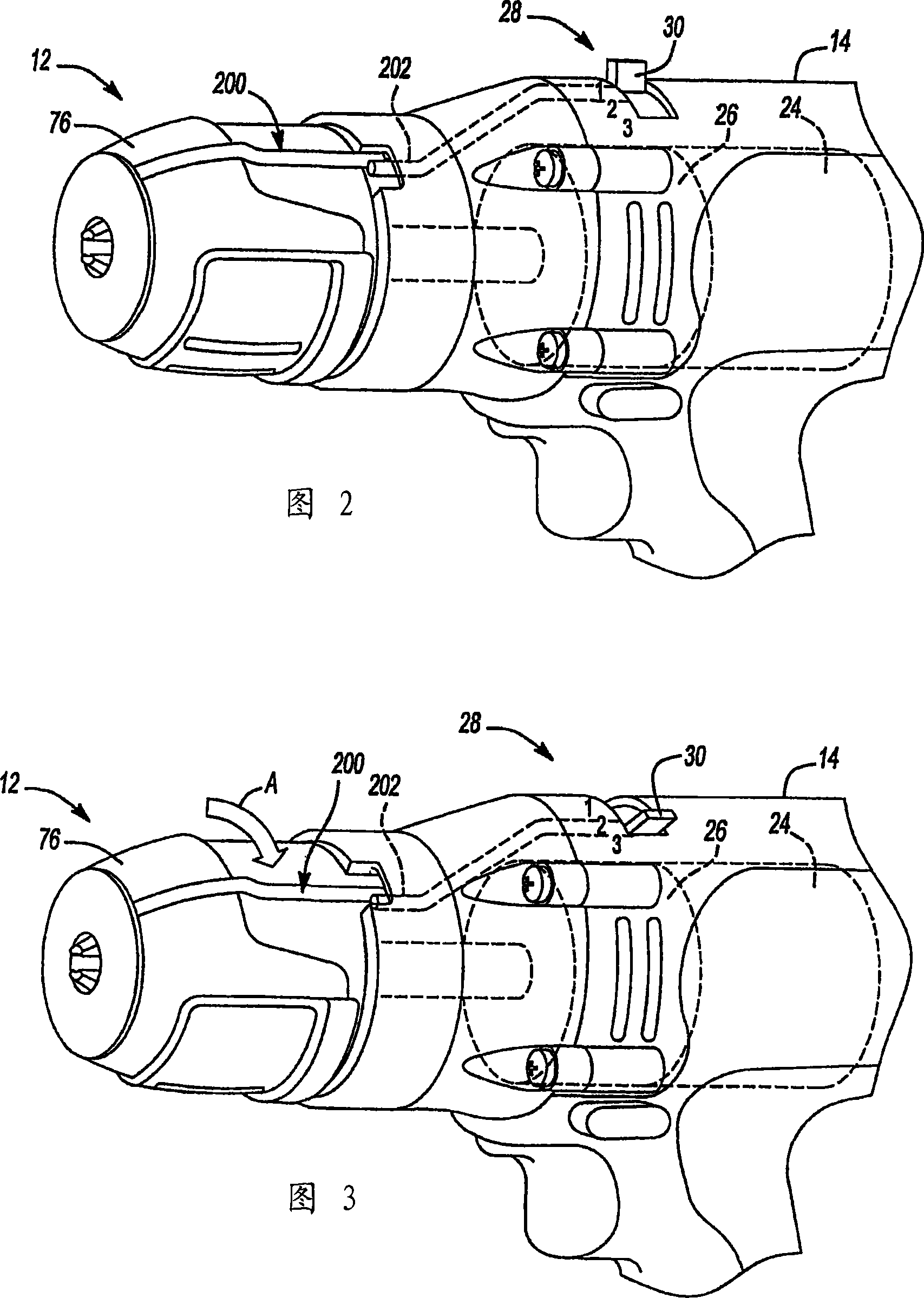

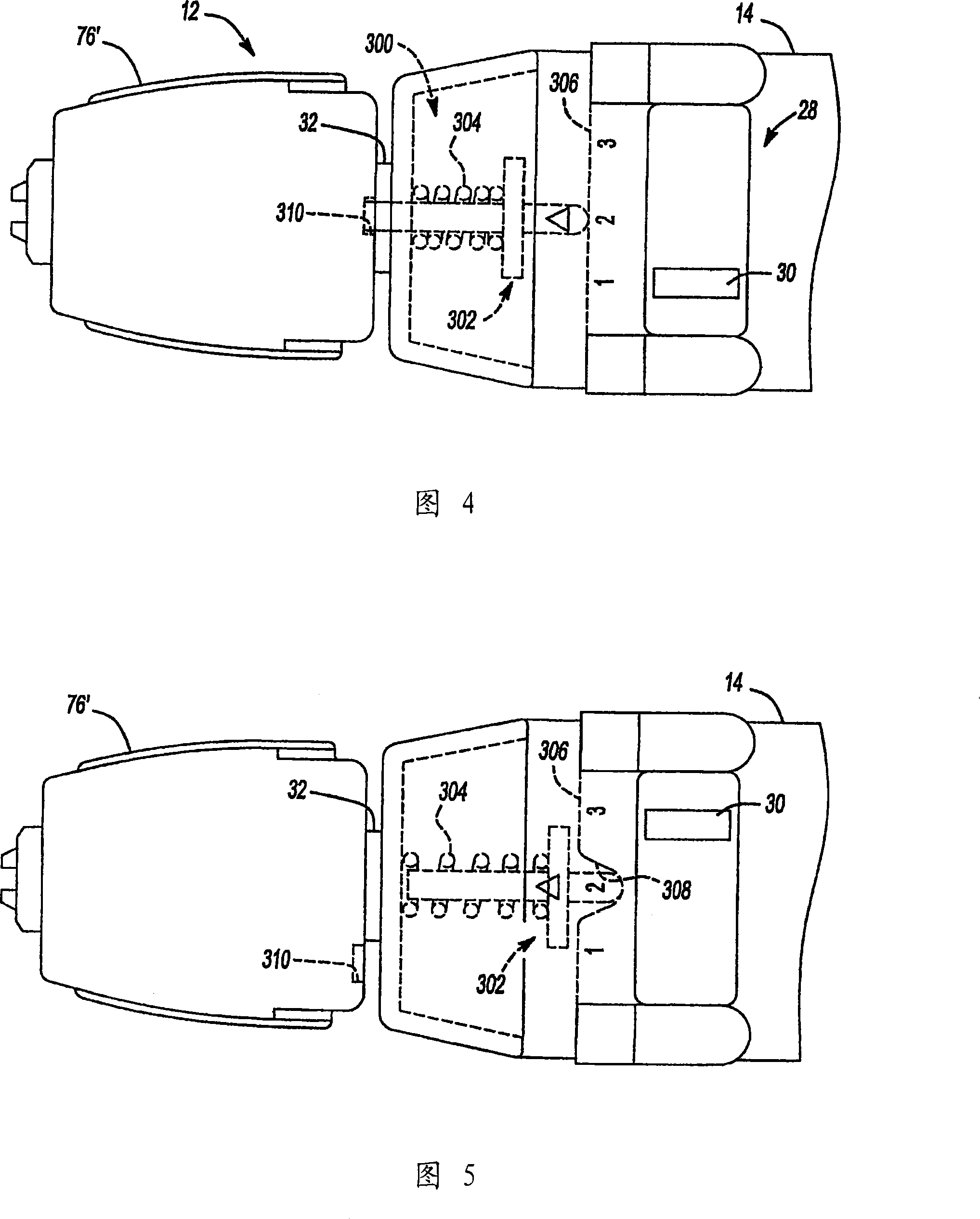

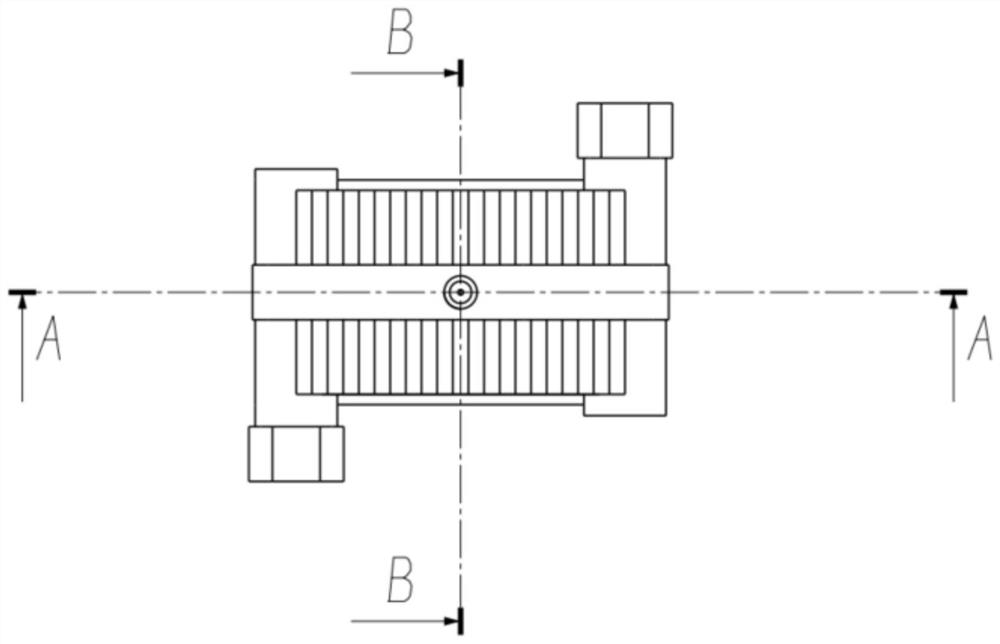

Drill chuck

A drill is provided with a chuck that is capable of being tightened or loosened by operation of the drill. The chuck includes a shift mechanism that interacts with the multi-speed transmission of the drill to ensure that the transmission is shifted into a desired gear ratio whenever the chuck is shifted from a drill mode to a chuck mode.

Owner:BLACK & DECKER INC

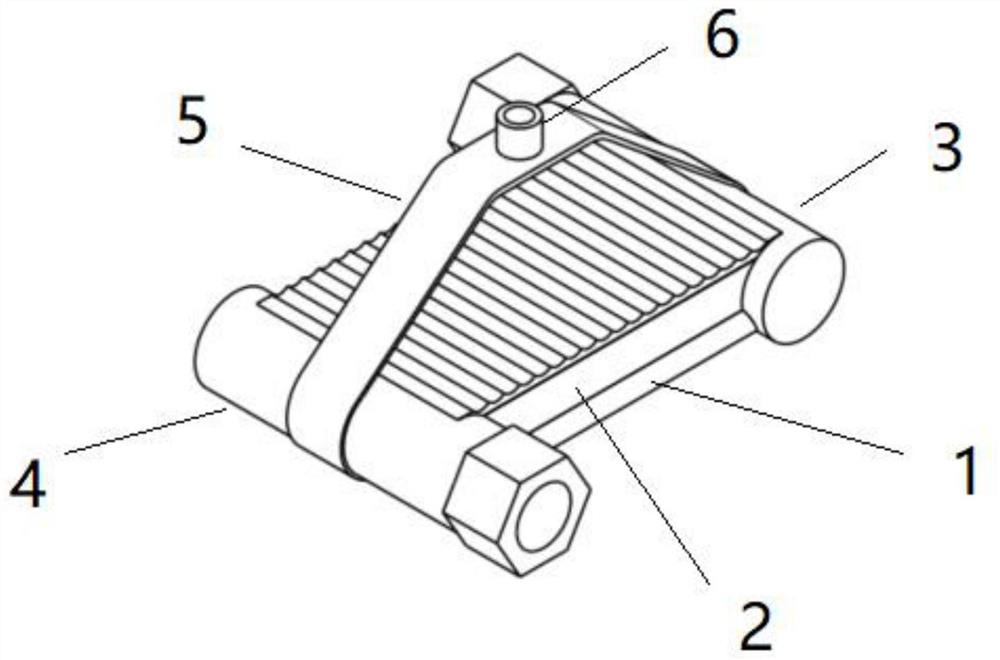

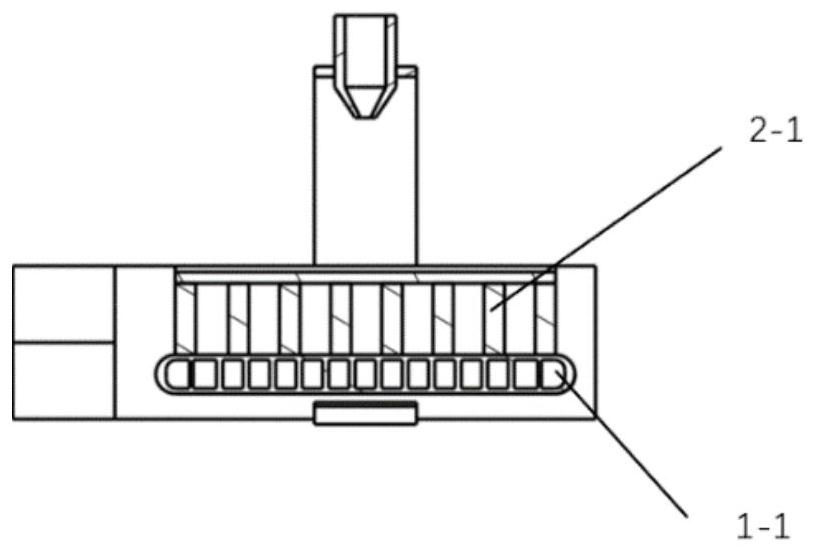

Three-stage phase change heat exchanger

The invention discloses a three-stage phase change heat exchanger, and is used for heat dissipation of a high-power component with ultrahigh heat flux. The heat exchanger comprises a heat exchanger main body, a cooling liquid nozzle and a supporting structure of the cooling liquid nozzle, wherein the heat exchanger main body comprises a metal harmonica- shaped tube, a metal or alloy solid-liquid phase change material cavity, an expansion heat dissipation surface outside the cavity and two end heads; and the cooling liquid nozzle and the supporting structure thereof comprise a supporting structure and a nozzle or a nozzle array. A refrigerant fluid working medium flows into the metal harmonica-shaped tube through the end head and absorbs heat led in from the lower wall surface of the harmonica-shaped tube, and a vaporized refrigerant flows out from the other end head of the metal harmonica-shaped tube. When the heat production is drastically increased, the metal or alloy solid material in the cavity is subjected to solid-liquid phase change, meanwhile, the nozzle at the top sprays atomized cooling (insulating) liquid, and the atomized cooling (insulating) liquid is in contact with the upper surface of a heat dissipation shell and absorbs heat to be vaporized; and extra instantaneous large heat flow heat is absorbed through two phase change latent heat of metal or alloy solid-liquid phase change and cooling liquid spray liquid-gas phase change, and it is guaranteed that the temperature of a high-power component is maintained within a certain range to work normally.

Owner:BEIHANG UNIV

Ceramic with invisible anti-counterfeiting function

The invention provides a ceramic with an invisible anti-counterfeiting function. A method comprises the steps of: 1) mixing high-temperature porcelain clay and anti-counterfeit powder in a ratio of 100 to (0.3 to 1.5) to obtain anti-counterfeiting porcelain clay; 2) mixing mixture of the anti-counterfeiting porcelain clay obtained in step 1), adding water with a mass fraction of 8% to 12%, water glass with a mass fraction of 0.3% to 0.4%, and American water with a mass fraction 0.1% to 0.3%, mixing for 1 to 3 hours, using a 120 to 180 mesh filter screen to filter, and producing slurry with a flow rate of 25m / s to 30m / s and a specific gravity of 160g / cm<3> to 180g / cm<3>; 3) pouring the slurry obtained in step 2) into a plaster mold, waiting for the slurry to solidify, and taking out an unfired brick; 4) after the step 3) is finished, drying and repairing the unfired brick at room temperature; 5) putting the unfired brick cleaned in the step 4) in a kiln for biscuit firing to obtain a biscuit; 6) glazing the biscuit prepared in step 5), and conducting high-temperature reduction and firing on a glazed body to obtain a finished product. The invention provides a permanent anti-counterfeiting technology ceramic, the ceramic is heat-resistant, and can satisfy industrial needs.

Owner:SHANGHAI GAOCHENG CREATIVE TECH GRP

Multi-vendor conditional access system

InactiveCN102172037AAchieve conversionLimit the scope of protectionTelevision system detailsAnalogue secracy/subscription systemsData packConditional access systems

The invention provides a smartcard, a head-end system and a conditional access system enabling incompatible receivers to be used in a vendor specific conditional access system. Hereto the smartcard stores an operation mode identifier, which is read upon insertion of the smartcard into the receiver and activation of the smartcard. The operation mode identifier is used to select a protocol for communication with the receiver. If the protocol is incompatible with the receiver, the operation mode identifier is changed and another protocol is selected upon reinsertion of the smartcard in the receiver. The head-end system uses data packet encapsulation to enable the receiver to forward EMMs and ECMs to the smartcard.

Owner:IRDETO ACCESS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com