SCM-12 molecular sieve and preparation method thereof

A molecular sieve and Z2O5 technology, applied in molecular sieve catalysts, including molecular sieve catalysts, molecular sieves and alkali-exchanged phosphates, etc., can solve problems that have not yet been discovered, and achieve the effects of thermal stability of the skeleton structure, good hydrothermal stability, and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

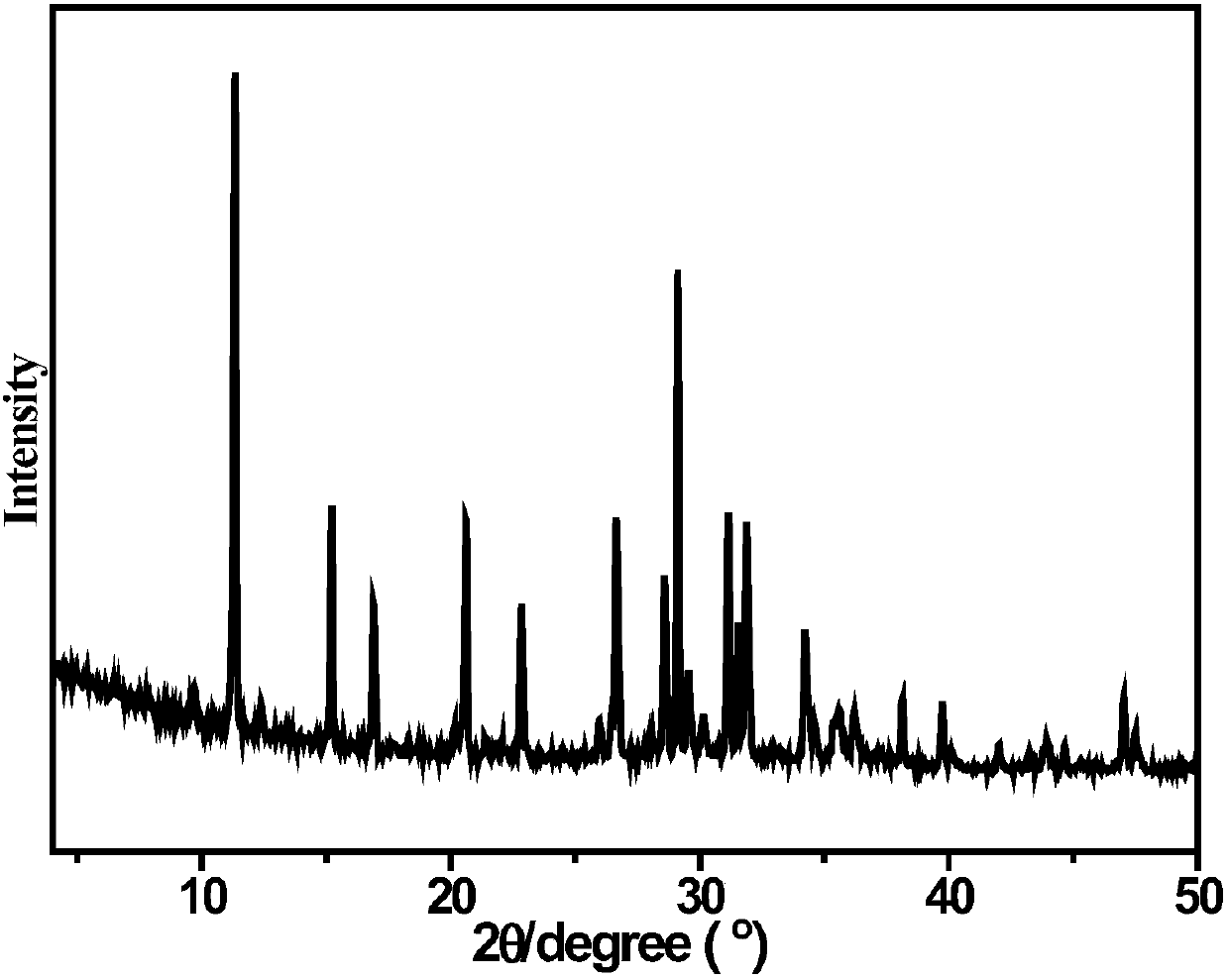

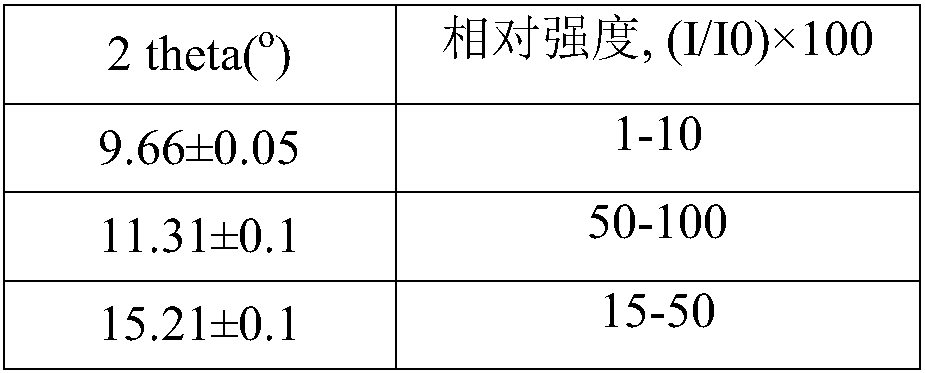

[0033] Synthesis of SCM-12 Molecular Sieve

[0034] 126.35g of zinc nitrate [Zn(NO 3 ) 2 ·6H 2 O] and 31.84g of aluminum sulfate [Al 2 (SO 4 ) 3 18H 2 O, purity ≥98wt.%] was dissolved in 410.36mL of water and 319.58mL of N,N-dimethylformamide [DMF] to make solution S, and 147.45g of phosphoric acid [H 3 PO 4 ,85wt.%], 27.51g tetraethylammonium hydroxide [TEAOH, 25wt%] and 160.85g of 1,2-bis(2-aminoethoxy)ethane [1,2-BEAE, purity ≥98wt. %] into S, stirred for 0.5h, and precipitated for 7h to obtain solution S', then put 31.16g of sodium hydroxide [NaOH] into S' for pretreatment at 80°C for 12h, and added mineralizer at 100°C Hydrofluoric acid [HF, 40wt.%] 70.39mL, closed and stirred for 9h. The above-mentioned stirred mixture was placed at 120°C for 14 days of crystallization, and the product was filtered and washed, dried at 80°C for 5 hours, then heated to 450°C, and roasted at a constant temperature for 12 hours to obtain the product. The specific material ratio of ...

Embodiment 2

[0039] Synthesis of SCM-12 Molecular Sieve

[0040] 11.91g of zinc sulfate [ZnSO 4 ·7H 2 O] and 2.36g of aluminum nitrate [Al(NO 3 ) 3 9H 2 O] was dissolved in 298.55mL of N,N-dimethylacetamide [DEF], mixed to make solution S, and 41.22g of ammonium dihydrogen phosphate [NH 4 h 2 PO 4 ], 21.16g of tetrapropylammonium hydroxide [TPAOH, 25wt%] and 19.75g of 1,2-bis(2-aminoethoxy)ethane [1,2-BEAE, purity ≥ 98wt.%] input In S, stir for 20 hours, sink for 3 hours to obtain solution S', then put 31.16g of potassium hydroxide [KOH] into solution S', stir well, place it at 70°C for hydrothermal treatment for 30h, and add ore at 110°C Chemical agent hydrofluoric acid [HF, 40wt.%] 39.65mL, closed and stirred for 5h. The above-mentioned stirred mixture was placed at 200°C for 10 hours to crystallize, the product was filtered and washed, dried at 80°C for 8 hours, then heated to 550°C, and roasted at a constant temperature for 9 hours to obtain the product. The specific material r...

Embodiment 3

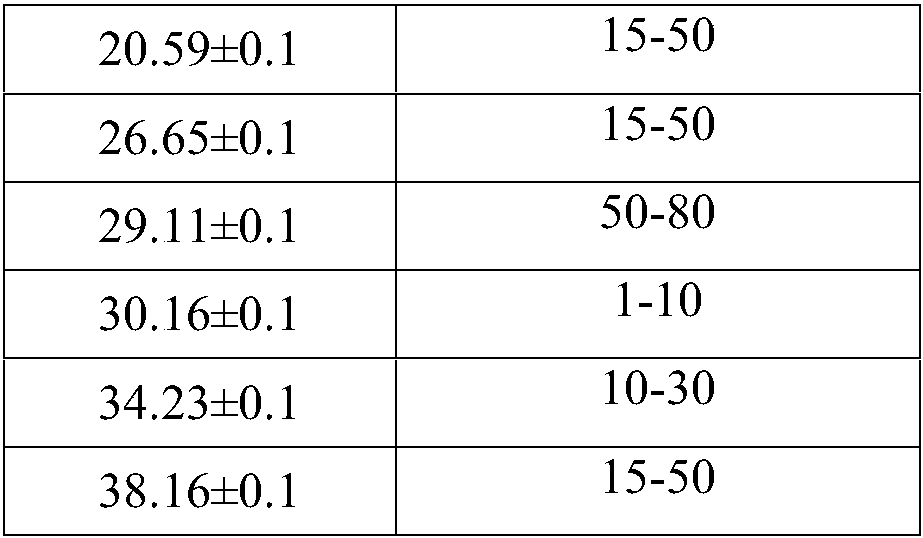

[0045] Synthesis of SCM-12 Molecular Sieve

[0046] 1098.23g of zinc nitrate [Zn(NO 3 ) 2 ·6H 2 O] and 998.61g of aluminum nitrate [Al(NO 3 ) 3 9H 2 O] was dissolved in 1949.10mL of ethylene glycol and 1212.37mL of water, mixed to make solution S, and 666.88g of diammonium hydrogen phosphate [(NH 4 ) 2 HPO 4 ] and 468.32g of 1,2-bis(2-aminoethoxy)ethane [1,2-BEAE, purity ≥ 98wt.%] were put into S, stirred for 10h, and precipitated for 10h to obtain solution S', then Put 97.35g of lithium hydroxide [LiOH] into S' for hydrothermal treatment at 120°C for 3.5h, and add mineralizer amine fluoride [NH at 120°C 4 F] 239.61g, sealed and stirred for 12h. The above stirred mixture was placed at 155°C to crystallize for 7 days. The product was filtered and washed, then dried at 80°C for 9 hours, then heated to 650°C, and roasted at constant temperature for 9 hours. The diffraction data are shown in Table 4.

[0047] Table 4

[0048] 2theta(°)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com