Light-emitting device test all-in-one machine

A technology of light-emitting devices and all-in-one machines, which is applied in optical instrument testing, machine/structural component testing, and optical performance testing, and can solve the time-consuming and labor-intensive testing of optical parameters of light-emitting components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the accompanying drawings.

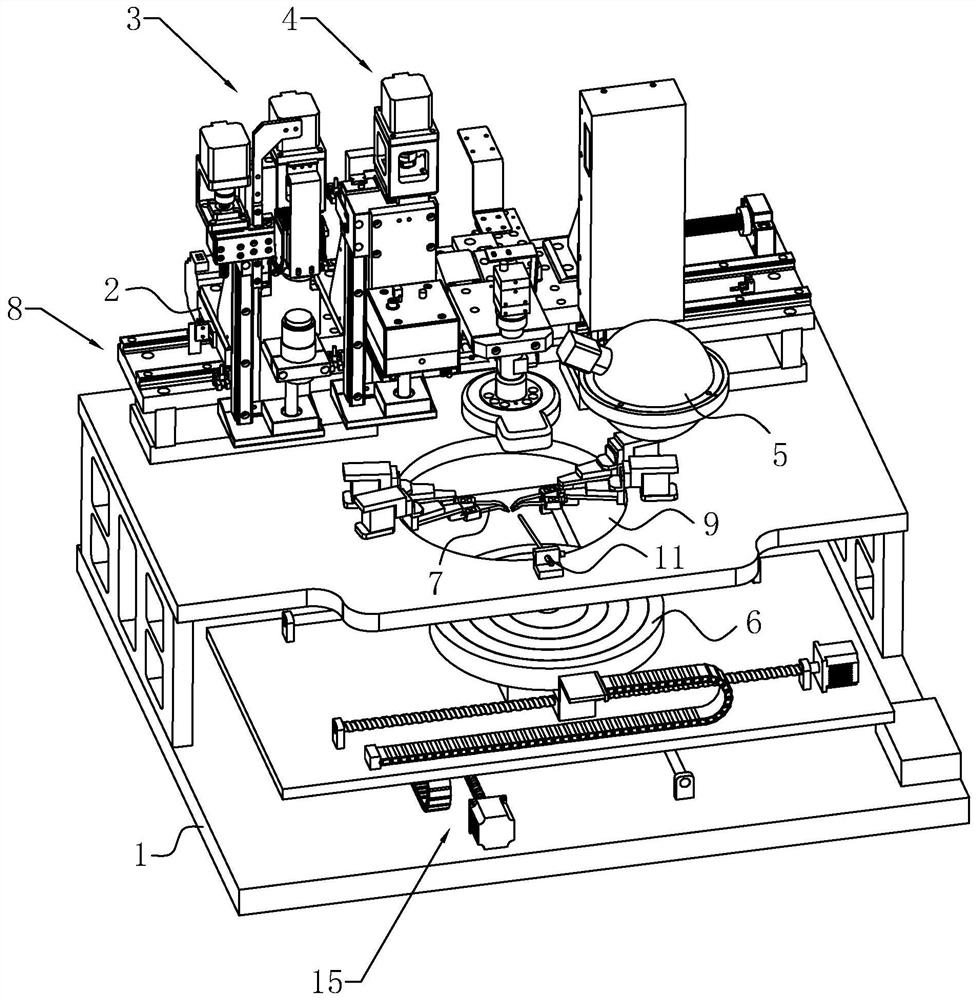

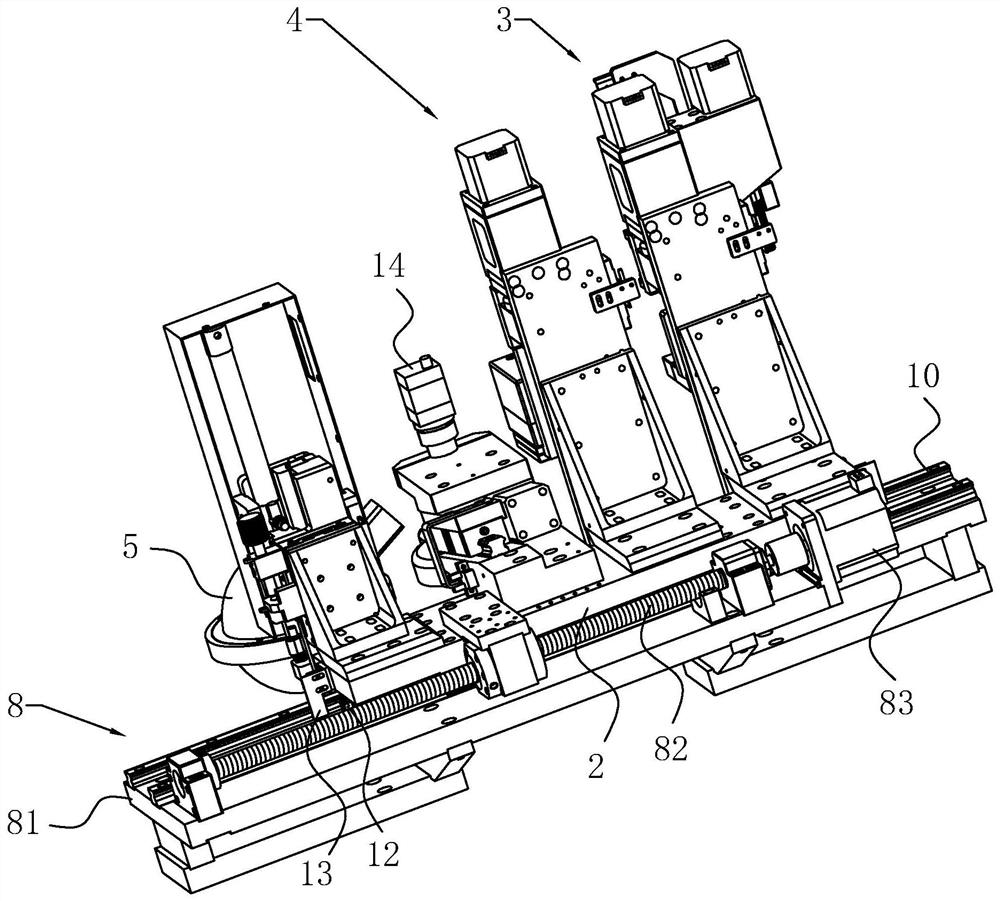

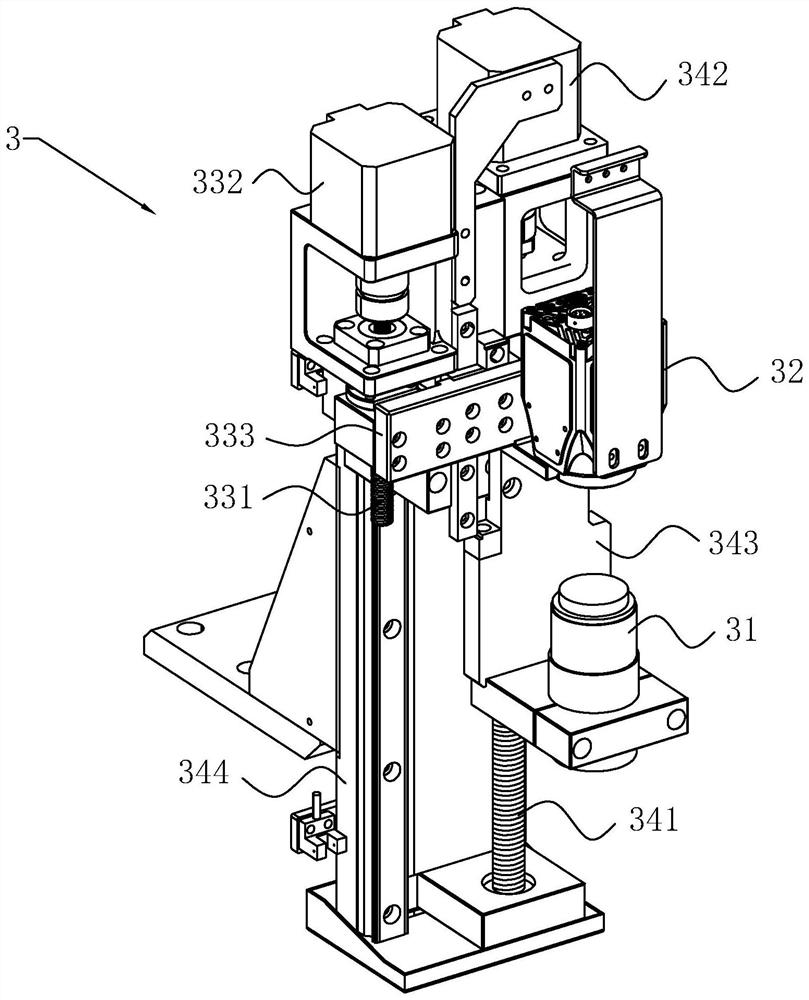

[0028] A light-emitting device test one machine, such as figure 1 As shown, including the seat 1, the seat 1 includes a first side surface and a second table surface spaced between the first table, the area of the first side surface is greater than the area of the second side, and the first side surface is located directly below the second side. . Among them, the second platform has a gap 9 that penetrates its upper and lower surfaces, allowing the gap 9 to be circulated; the second plan is located at a space 9 installed four test needles 7 and blowing parts 11, four tests The needle 7 is bent down and is close to the center of the gap 9, and the air blowing port of the blowing member 11 is toward the tip of the test needle 7; there is a slide table 6, which is located between the first side and the second side surface. The tablet 6 is used to carry the measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com