Transfer printing method and transfer printing head based on liquid capillary force and surface tension

A technology of surface tension and capillary force, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of flexible electronic device film device damage, low yield, unsatisfactory transfer effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Exemplary embodiments of the present invention are described below with reference to the accompanying drawings. It should be understood that these specific descriptions are only used to teach those skilled in the art how to implement the present invention, but are not intended to exhaust all possible ways of the present invention, nor are they intended to limit the scope of the present invention.

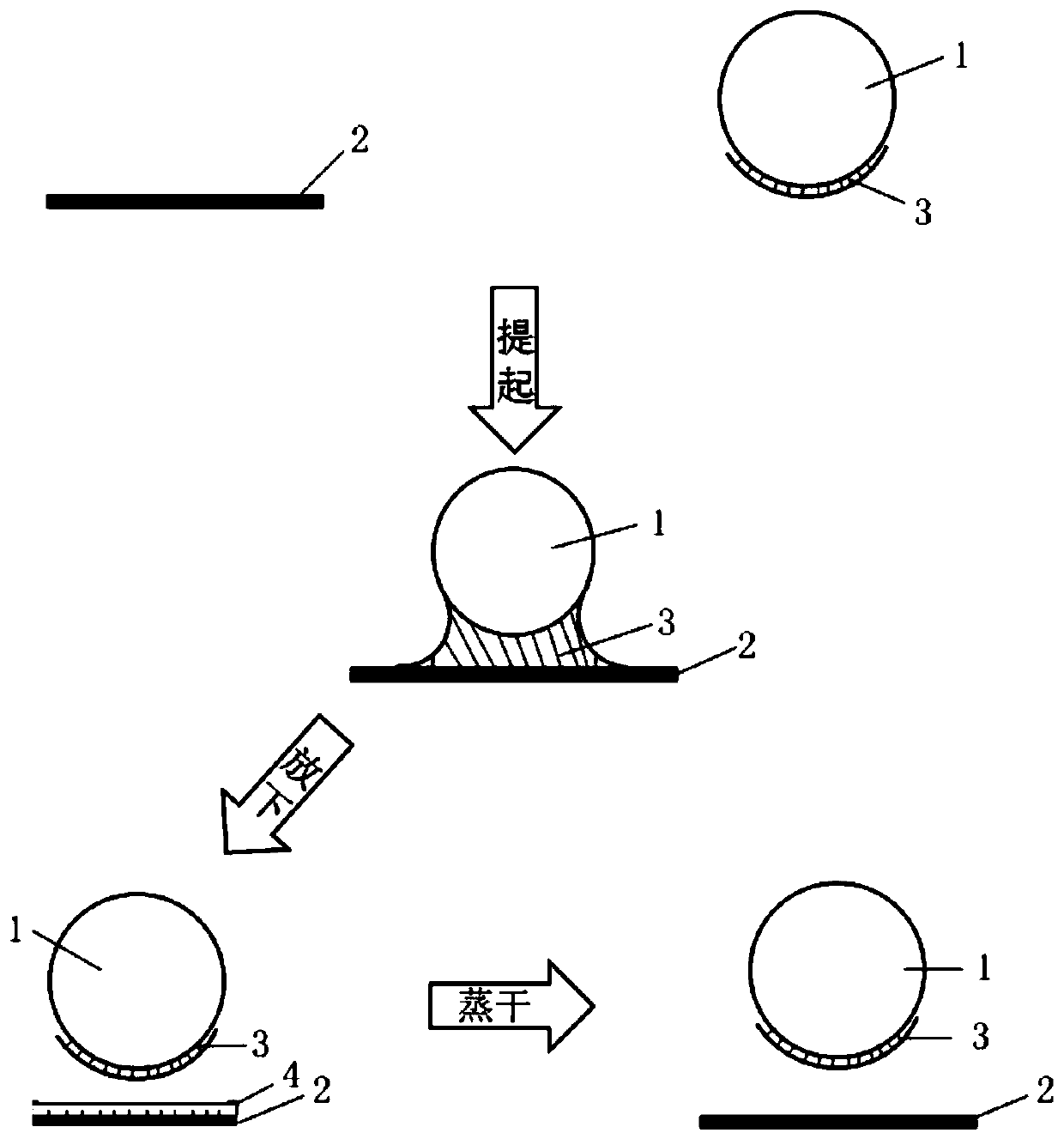

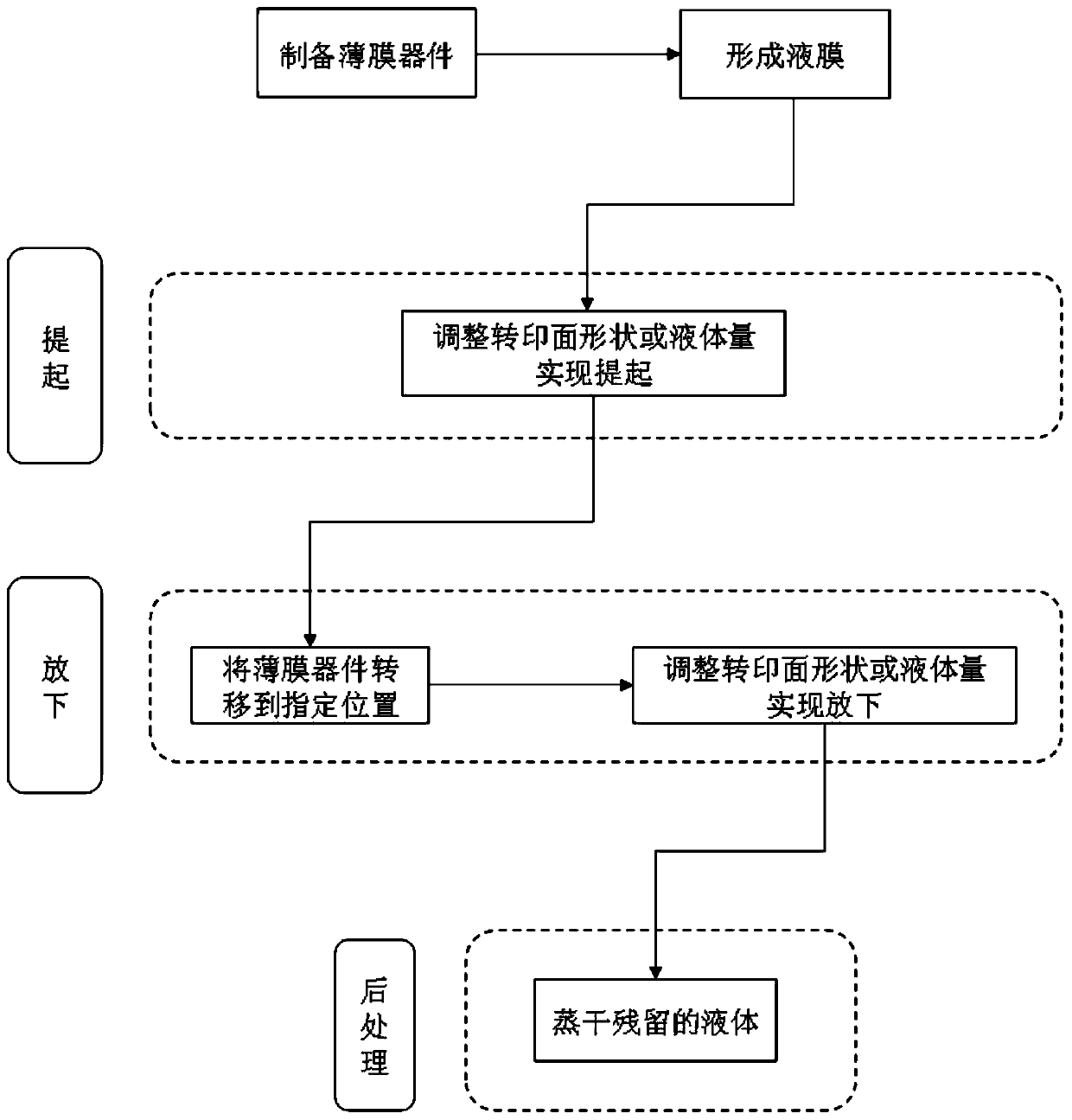

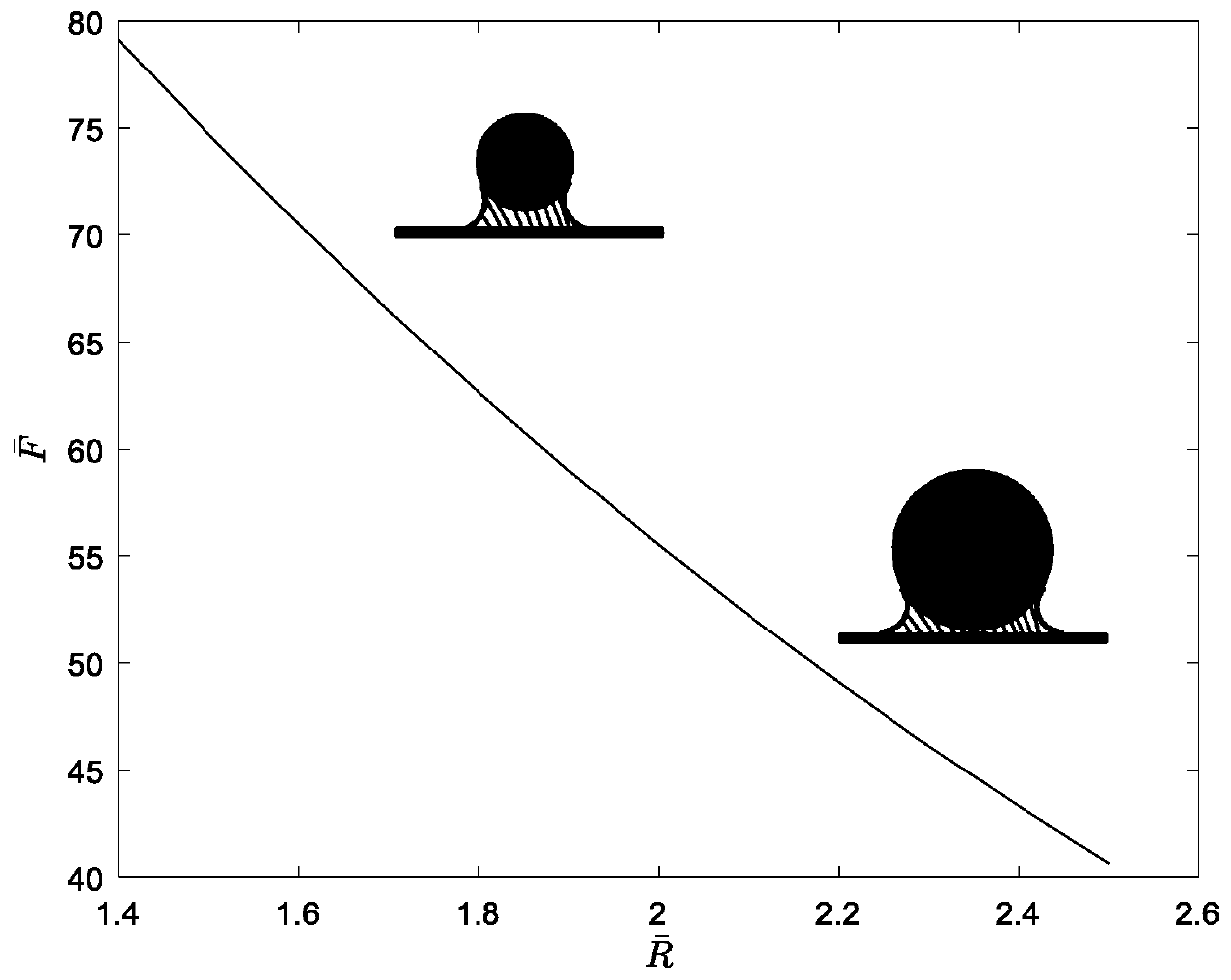

[0037] Such as figure 1 and figure 2 As shown, the present disclosure provides a transfer printing method based on liquid capillary force and surface tension, which utilizes a transfer head 1 to separate a thin film device 2 from an original substrate. In a specific embodiment, the transfer printing method comprises the following steps:

[0038] The preparation step of the thin film device 2: forming the thin film device 2 on the original substrate.

[0039] The liquid film 3 forming step: apply liquid on the transfer surface of the transfer head 1, the liquid can form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com