A telescopic pipe flow energy harvester

A pipeline flow and energy harvester technology, applied to piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve economic losses, limited battery life, and oil and gas pipeline leakage and other issues to achieve the effect of strong power generation capacity, effective frequency bandwidth and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

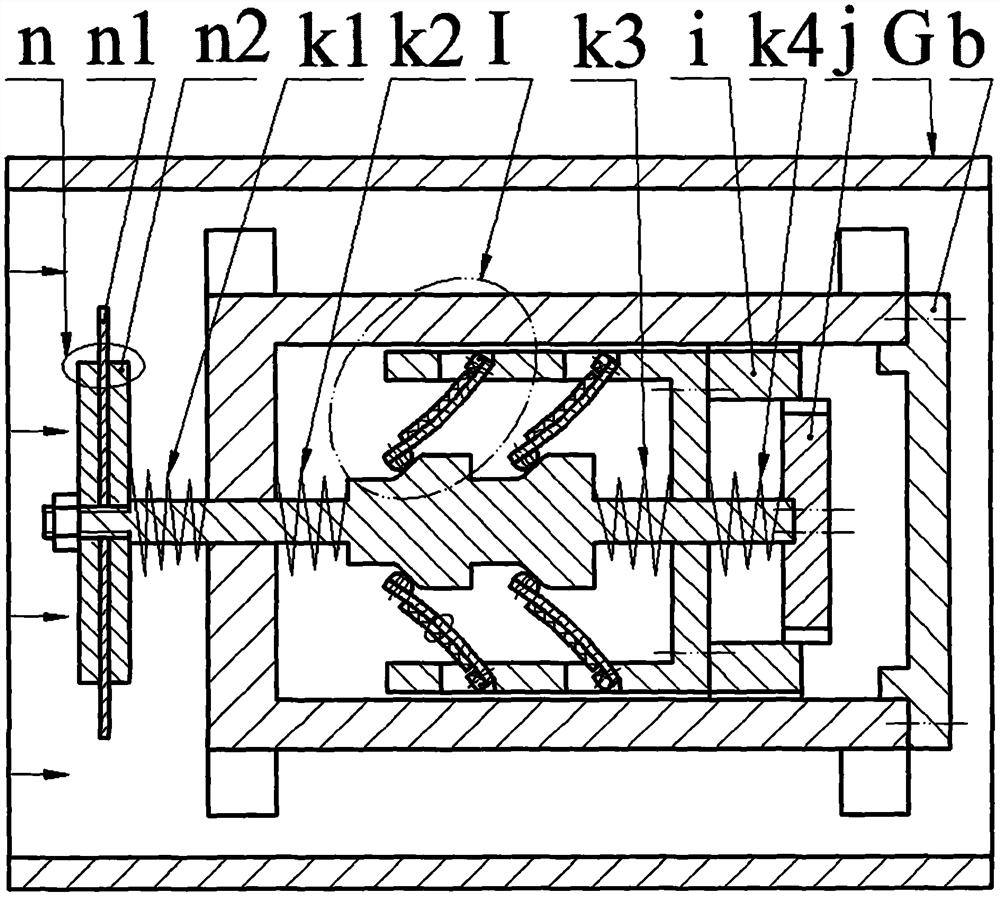

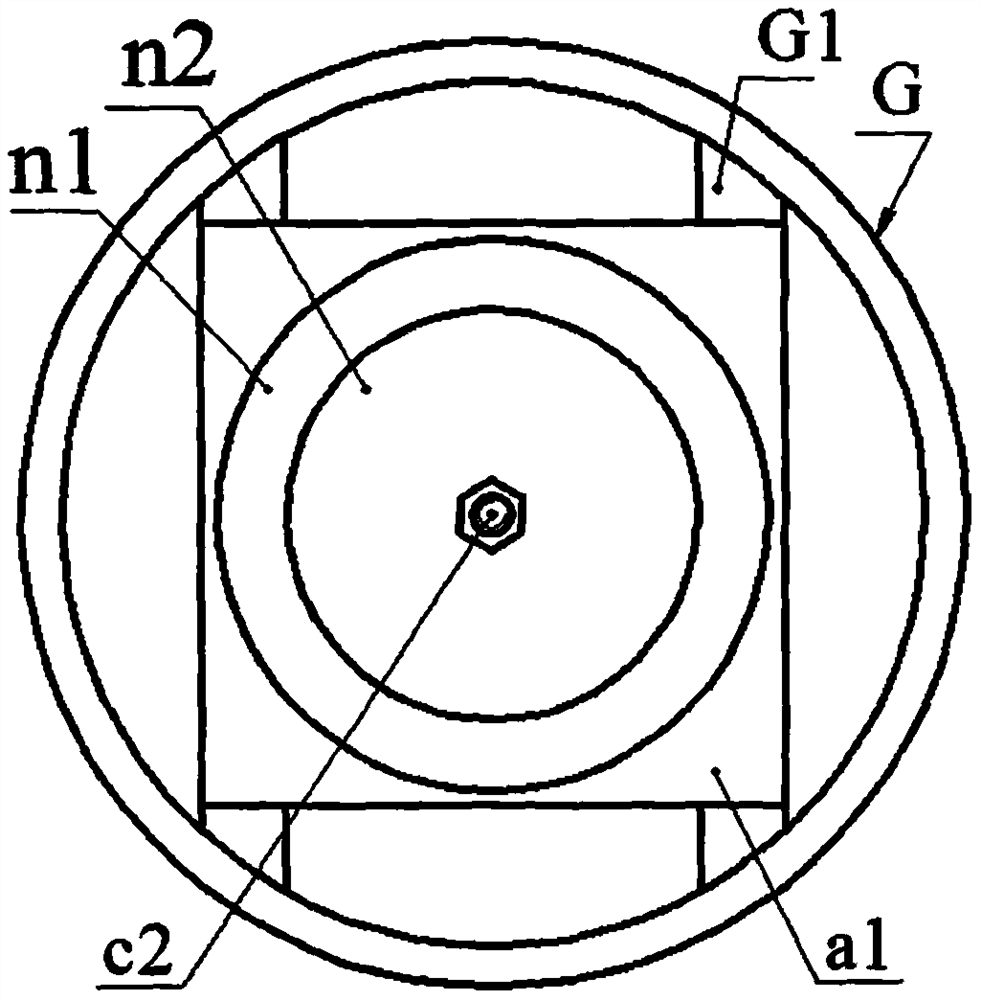

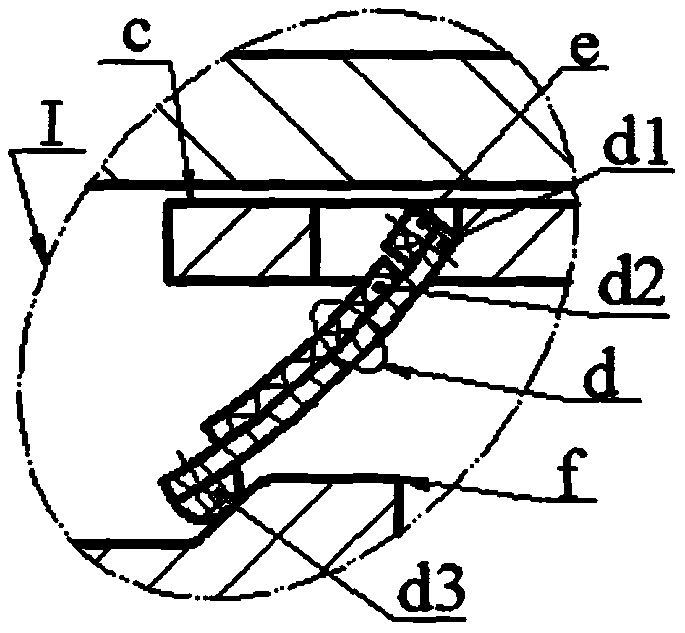

[0013] On the inner wall of the pipe G, a shell a is installed through the radial plate G1, and the end of the side wall a2 of the shell a is installed with an end cover b through screws; the center of the vertical plate c1 of the bracket c is provided with an inner pin hole c2, and the upper and lower sides of the same side Both ends are provided with a horizontal plate c4, and the horizontal plate c4 is provided with an inclined installation surface c5, the installation surface c5 is located on the wall of the hole on the horizontal plate c4, and the acute angle c6 formed by the installation surface c5 and the horizontal plate c4 is the installation angle. The installation angle is greater than 30 degrees; the left and right ends of the actuator f are respectively provided with a left pin f4 and a right pin f7, the left pin f4 and the right pin f7 are coaxial, and the upper and lower sides of the actuator f are along the left pin f4 and the right pin f7 There are multiple cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com