A hole-groove type crop seedling transplanting machine

A technology for transplanting machines and crops, applied in the field of transplanting machines, can solve problems such as insufficient technology and increased transplanting costs, and achieve the effects of reducing transplanting costs, wide application range, and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

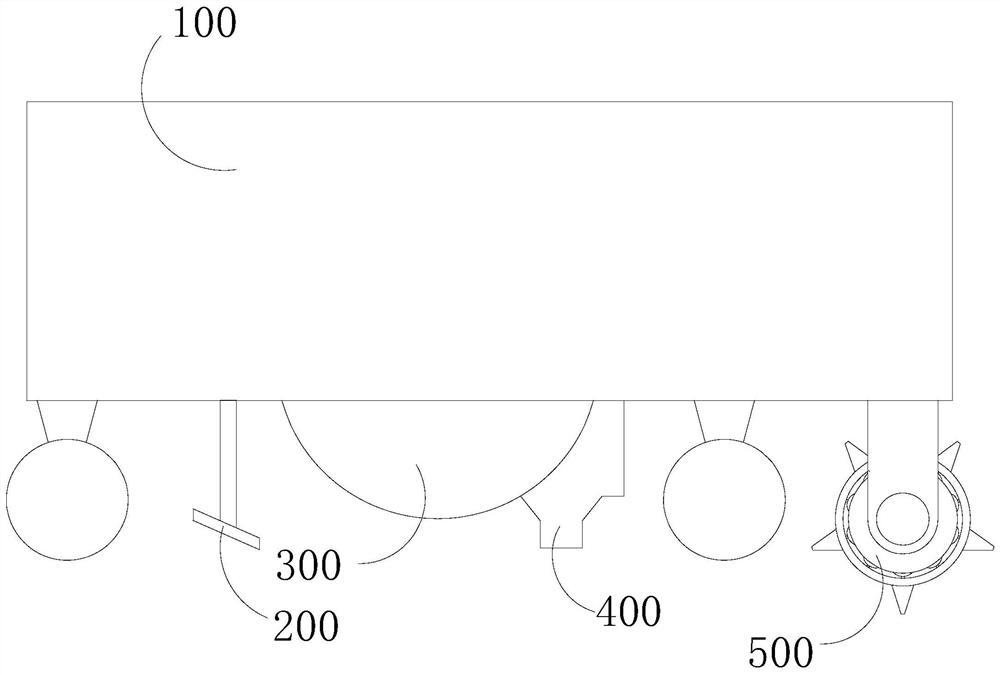

[0032] see Figure 1-6 , the present invention provides a technical solution of a hole-type crop seedling transplanting machine: its structure includes a transplanting machine body 100, a soil covering device 200, a seedling export core plate 300, a seedling export bucket 400, and a hole opening device 500. The transplanting machine body 100 is provided with a soil covering device 200, a pot seedling export core plate 300, a pot seedling export bucket 400, and a hole opening device 500 from left to right. The pot seedling export core plate 300 and the pot seedling export bucket 400 Connected, the setting of the soil covering device 200 is that after the pot seedlings are transplanted, the soil around the hole can be pushed into the hole to cover the pot seedlings with soil;

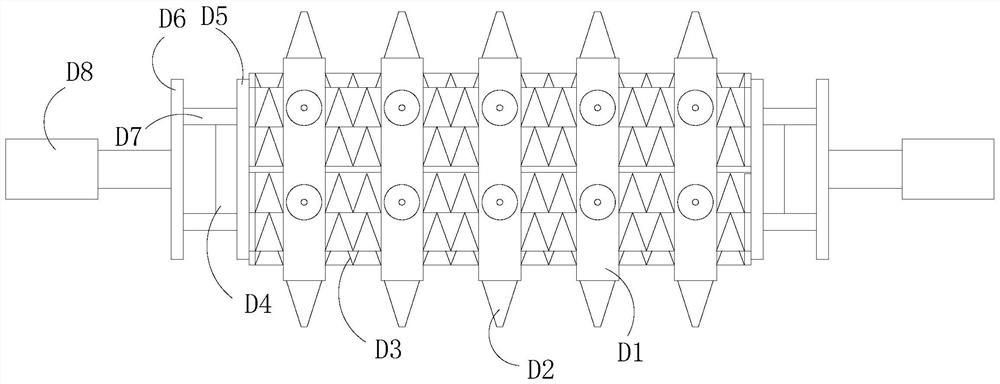

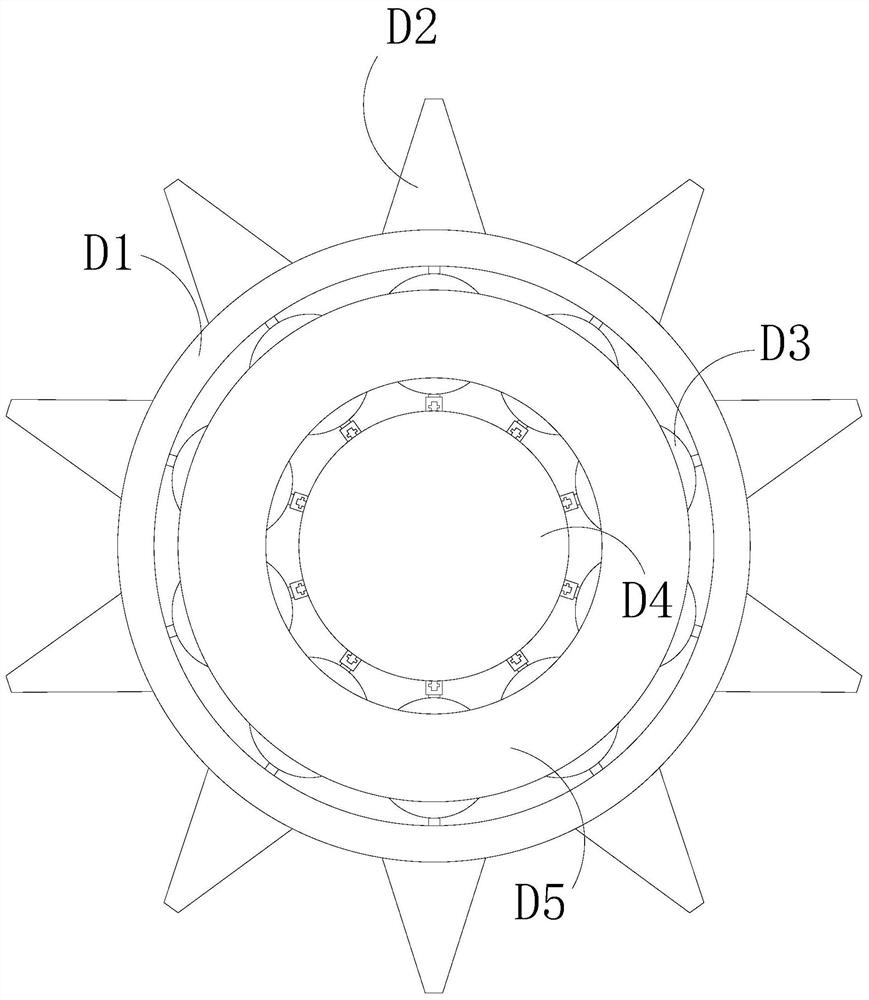

[0033] The hole opening device 500 includes a mounting plate D1, a hole opening cone D2, a high-strength spring group D3, a central shaft D4, a connecting ring D5, a connecting plate D6, a connecting rod ...

Embodiment 2

[0040] see Figure 1-9 , the present invention provides a technical scheme of a hole-type crop seedling transplanting machine: its structure includes a transplanting machine body 100, a soil covering device 200, a seedling export core plate 300, a seedling export bucket 400, and a hole opening device 500. The transplanting machine body 100 is provided with a soil covering device 200, a pot seedling export core plate 300, a pot seedling export bucket 400, and a hole opening device 500 from left to right, and the pot seedling export core plate 300 is connected with the pot seedling export bucket 400 Generally speaking, the setting of the soil covering device 200 is that after the pot seedlings are transplanted, the soil around the hole groove can be pushed into the hole groove to cover the pot seedlings with soil;

[0041] see Figure 2-4 The hole opening device 500 includes a mounting plate D1, a hole opening cone D2, a high-strength spring group D3, a central shaft D4, a conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com