Jacketed pot for soaking tripes

A technology of jacketed pot and hairy belly, applied in food science and other directions, can solve problems such as inconvenience of operation, and achieve the effects of reducing labor intensity, simple discharging operation and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

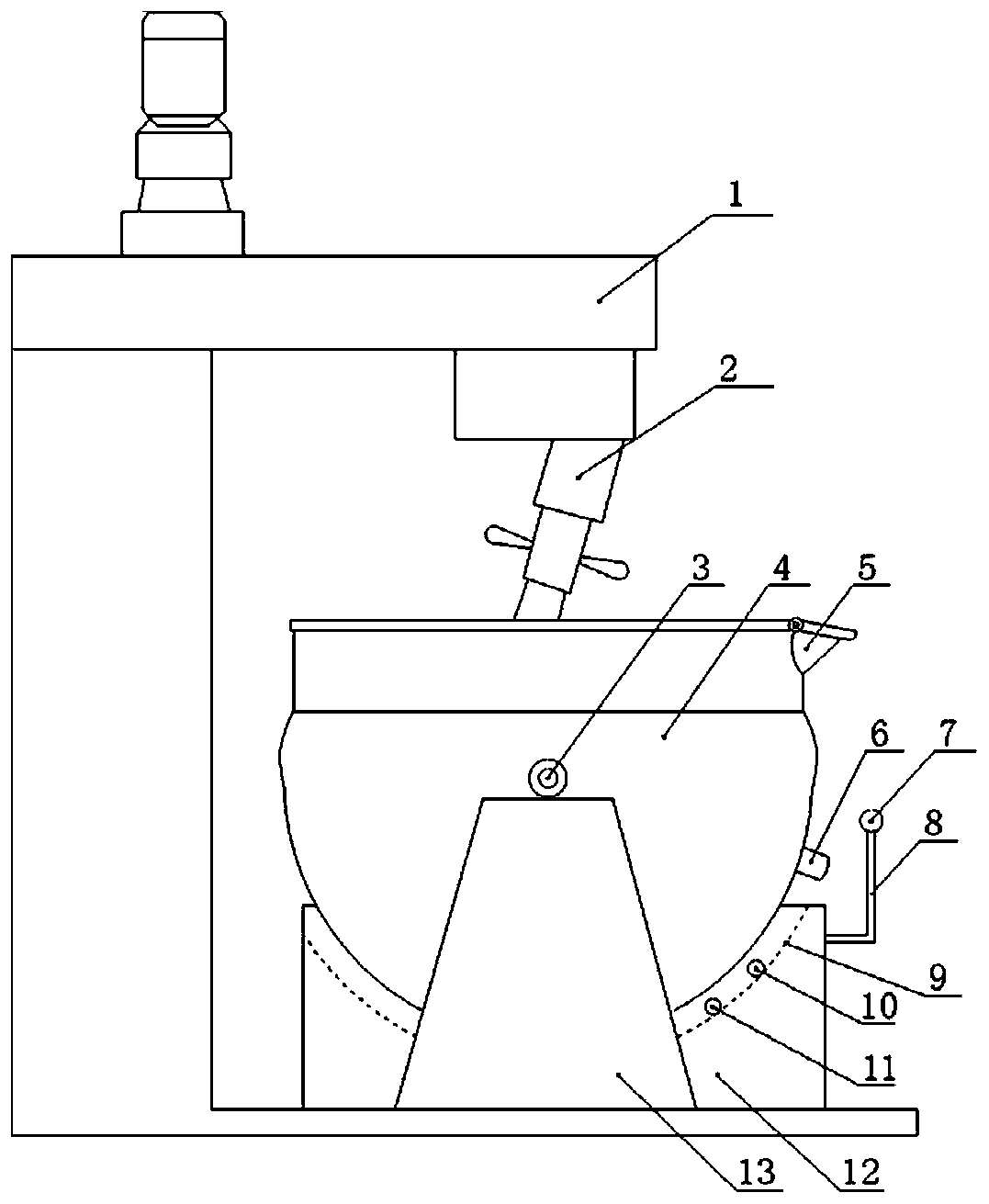

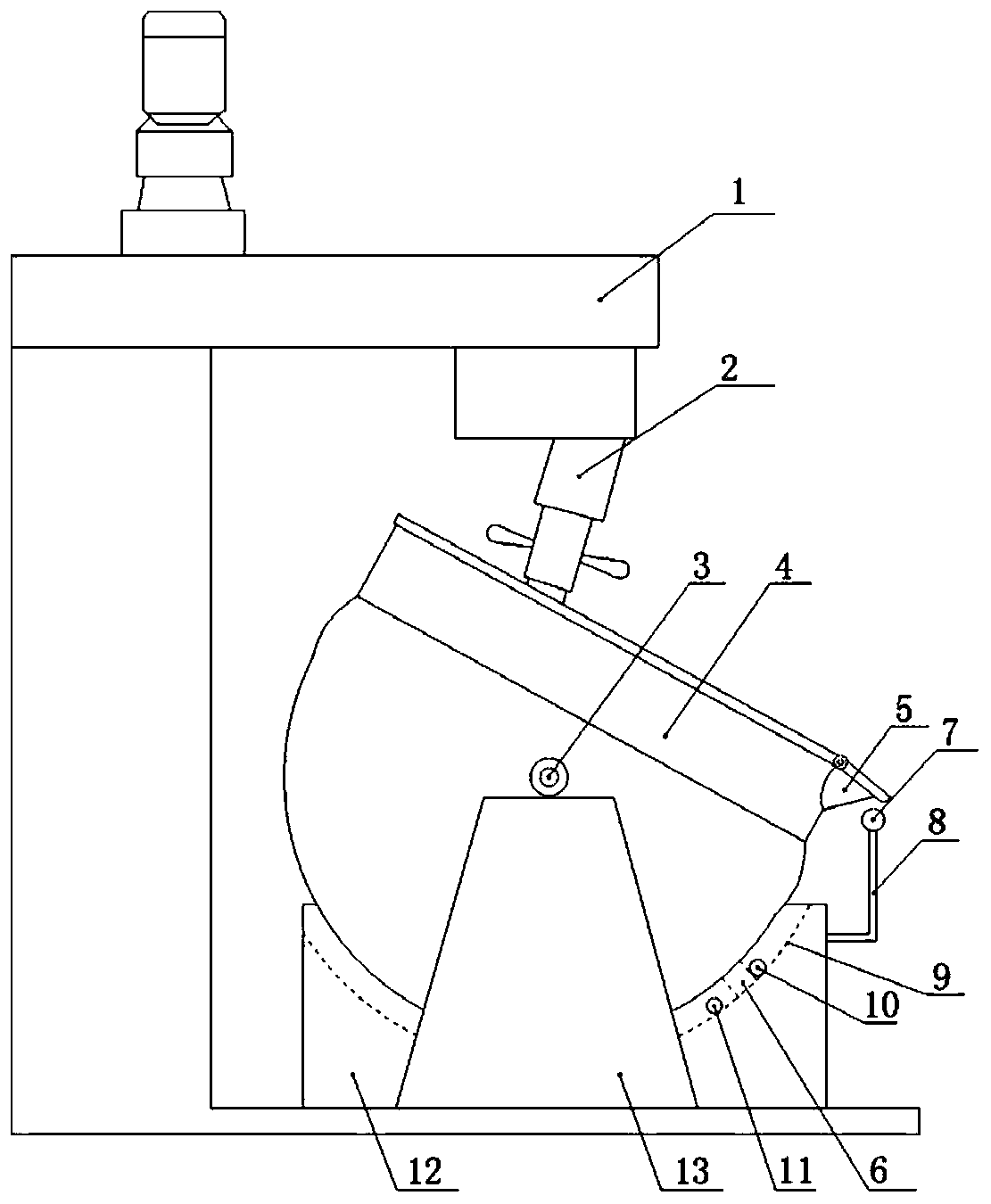

[0026] Such as figure 1 Shown, a kind of sandwich pot for tripe foaming, comprises pot body 4 and support 13, and pot body 4 is connected on the support 13 in rotation, and the joint of pot body 4 and support 13 is connected with handle 3 so that hold to rotate pot Body 4. A stirring shaft 2 is arranged to rotate inside the pot body 4, and the stirring shaft 2 is controlled to rotate through the hydraulic system 1. A water outlet valve is installed at the bottom of the pot body 4, and a steam inlet and outlet valve is connected to one side of the pot body 4.

[0027] The bottom of the pot body 4 is equipped with a support seat 12 for supporting the pot body 4 , and the top of the support seat 12 is arc-shaped matching with the shape of the bottom of the pot body 4 . The top of the support base 12 is provided with a chute 9 along its length direction, the pot body 4 is welded with a slider 6 , and the slider 6 is slidably connected in the chute 9 . The cross section of the c...

Embodiment 2

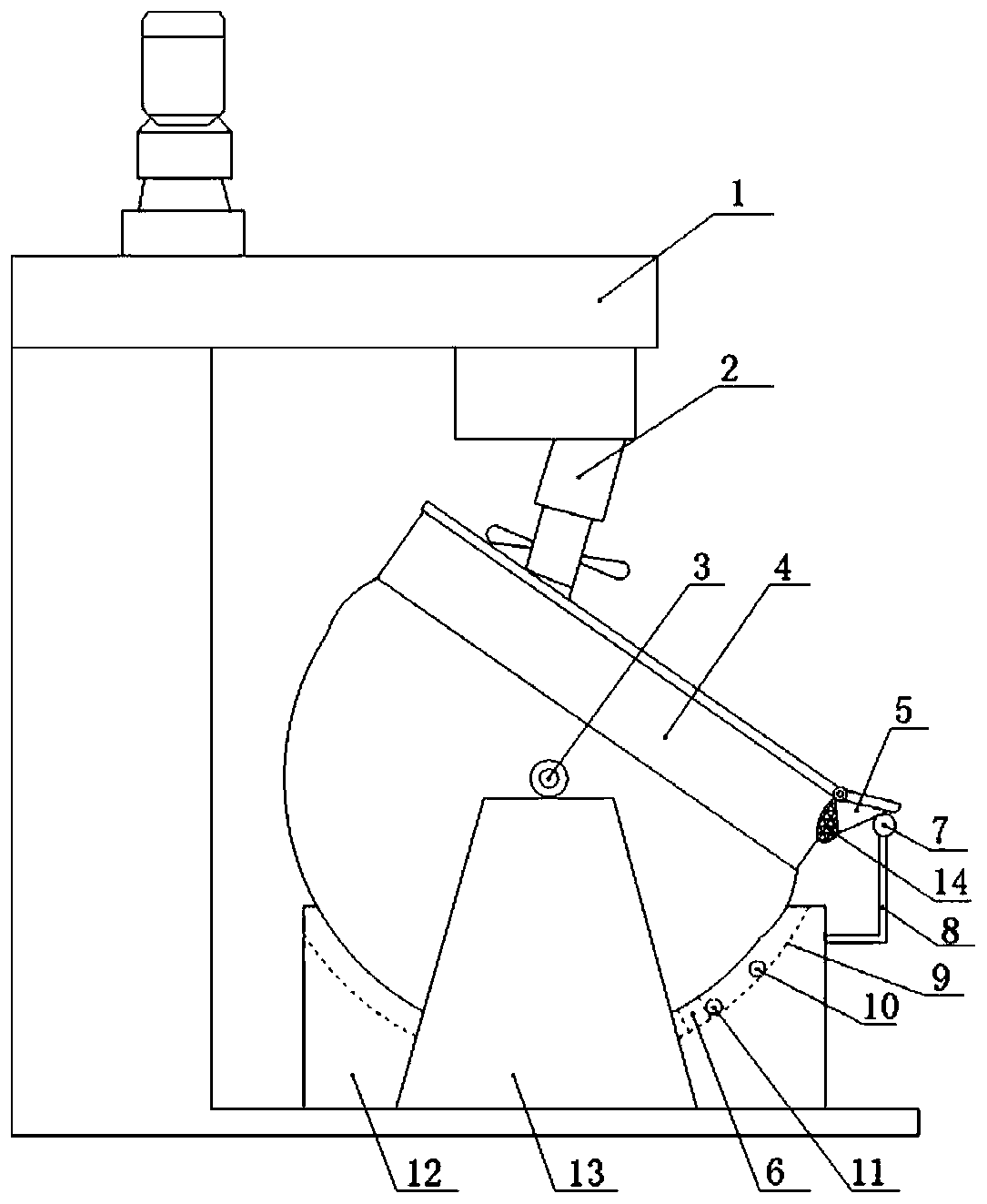

[0037] The difference between this embodiment and the first embodiment is that the ends of the discharge wedge 10 and the drainage wedge 11 protruding from the support seat 12 are vertically connected with pull rods, and the two pull rods are respectively coated with different colors. With such arrangement, the staff can pull the discharge wedge 10 or the drainage wedge 11 through the pull rod without bending over, which is convenient to operate. The two pull rods are painted in different colors to facilitate the identification of the staff, so as to switch the draining or discharging state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com