Multi-layer filter bag type filter

A filter and filter bag technology, which is applied in the field of multi-layer filter bag filters, can solve the problems of inability to meet high-standard slurry production requirements and unsatisfactory filtering effects, achieve ideal filtering effects, improve filtering effects, and meet production requirements. effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below.

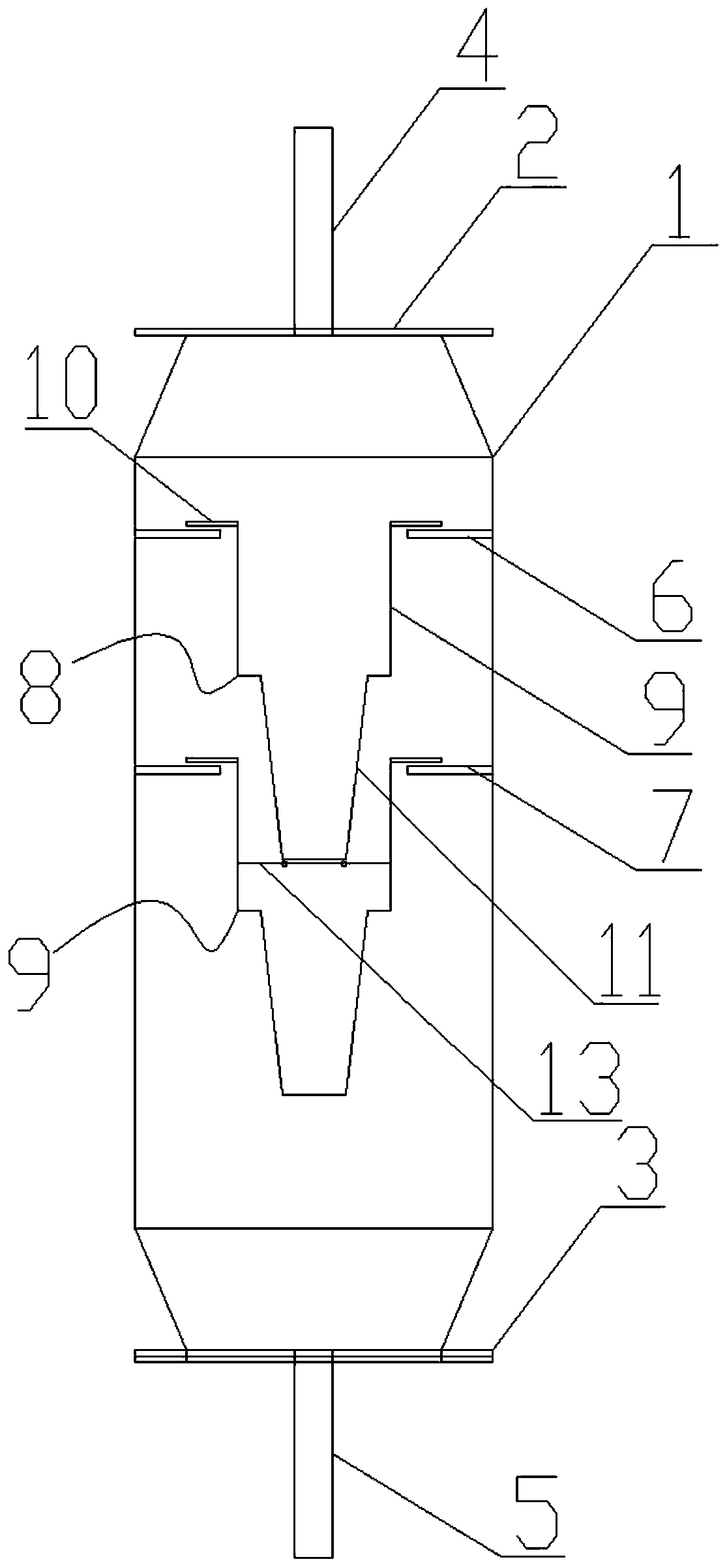

[0015] Such as figure 1 As shown, a multilayer filter bag 11 type filter includes a cylinder body 1, a first filter mechanism 8 and a second filter mechanism 9; the upper and lower ends of the cylinder body 1 are fixedly connected with an upper end cover 2 and a lower end by bolts respectively Cover 3, the upper part of the upper end cover 2 is connected with the feed pipeline 4, and the lower part of the lower end cover 3 is connected with the discharge pipeline 5;

[0016] An upper annular plate 6 and a lower annular plate 7 are fixedly connected to the upper and middle parts of the cylinder body 1, respectively;

[0017] The first filter mechanism 8 and the second filter mechanism 9 have the same structure, and both are composed of a sleeve 12 with two ends open on the upper part and a filter bag 11 connected to the lower open end of the sleeve 12, wherein the upper end of the sleeve 12 is fixedly connected to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap