Road and railway transportation wagon group and marshalling method thereof

A technology for road-rail dual-purpose and vehicle groups, which is applied in the direction of track and road dual-purpose vehicles, transportation and packaging, railway car body parts, etc., and can solve unevenness, large gaps between vehicles, and longitudinal force of one-way marshalling vehicles Transmission and other issues to achieve the effect of improving operating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

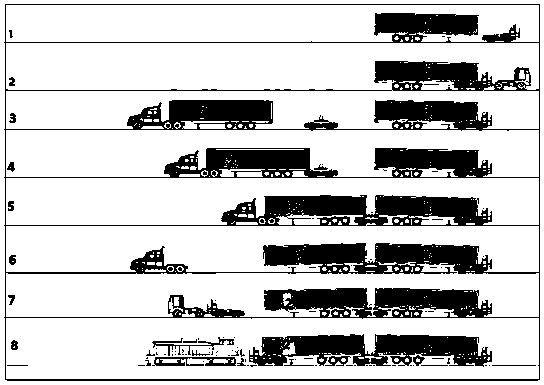

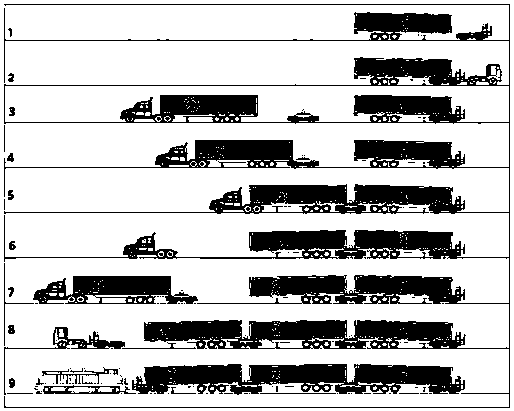

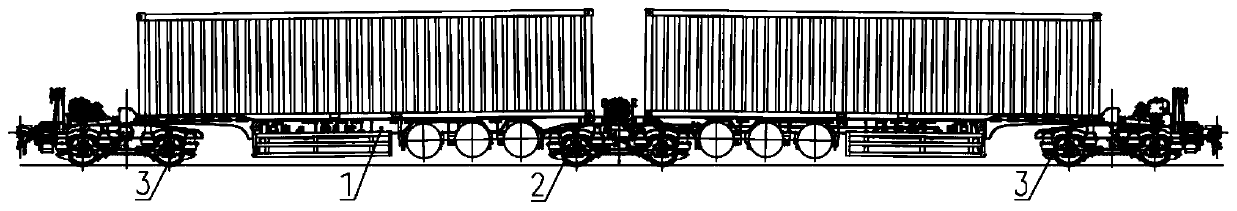

[0056] Embodiment one is basically as figure 1As shown: the present embodiment provides a road-rail dual-purpose transport vehicle group, which includes at least two road-rail dual-purpose semi-trailers 1, at least one articulated bogie 2 and two end bogies 3, the road-rail dual-purpose semi-trailer The number of trailers 1 is N and they are arranged sequentially along their traveling direction. N road-rail dual-purpose semi-trailers 1 are grouped into a group of railway transportation through two end bogies 3 and (N-1) intermediate joint bogies 2. For unit trains, the number N of road-rail dual-purpose semi-trailers 1 in the transport car group can be increased or decreased according to the organization of the supply of goods. The combination of road-rail dual-purpose semi-trailers 1 is convenient and flexible, and it is convenient and flexible to meet the needs of the railway transportation of goods. needs, it is beneficial to improve transportation performance, reduce trans...

Embodiment 2

[0061] Embodiment 2 is basically the same as Embodiment 1, the difference is that: as a preference of Embodiment 1, the train set connecting plate 221 provided in this embodiment is specifically a dumbbell-shaped symmetrical flat plate structure, and a fixed mounting seat 23 is arranged in the middle , the car group connecting plate 221 is fixed on the knuckle bogie 2 frame through the fixed mounting seat 23, to ensure the stability of the center support at the two ends of the car group connecting plate 221; and the car group at both ends of the car group connecting plate 221 Mounting holes are all arranged on the connecting section; and the upper end surface and the lower end surface of the connecting hanger 222 of the train group are provided with the corresponding round pin 223 holes of the train group connecting the hanging plate 221 end mounting holes, so that the train The car group connecting hanging sections at both ends of the group connecting hanging plate 221 are res...

Embodiment 3

[0067]The third embodiment is basically the same as the second embodiment, the difference is: please refer to Figure 7 to Figure 10 As shown, the end bogie 3 provided in this embodiment includes an end welding frame 31, specifically, the end connecting device 32 includes an end connecting plate 321, an end connecting seat 322 and an end connecting round pin 323 , the end connecting plate 321 includes a fixed section and an end connecting section, the end connecting plate 321 is connected with the end welding frame 31 through the fixing section, and the end connecting seat 322 is located on the road-rail dual-purpose semi-trailer of the transport vehicle group 1. In the front end beam 111 at the end, one end of the end bogie 3 is inserted into the end connection seat 322 through the end connection section, and passes through the end connection plate through the end connection round pin 323 from bottom to top 321 and the end connect the hanger seat 322 upper end connection seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com