Automatic permanent magnet lifter

A permanent magnet lifter and lifter technology, which is applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of inconvenient operation, affecting lifting work efficiency, and high safety factor, so as to reduce personnel operation steps and improve The effect of lifting work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

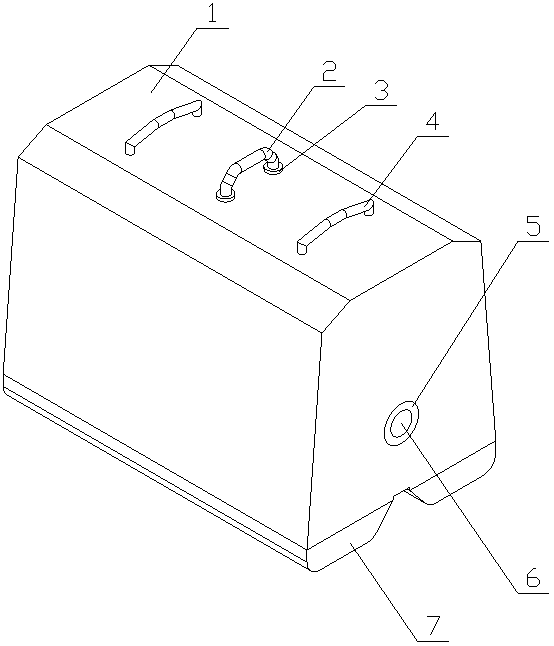

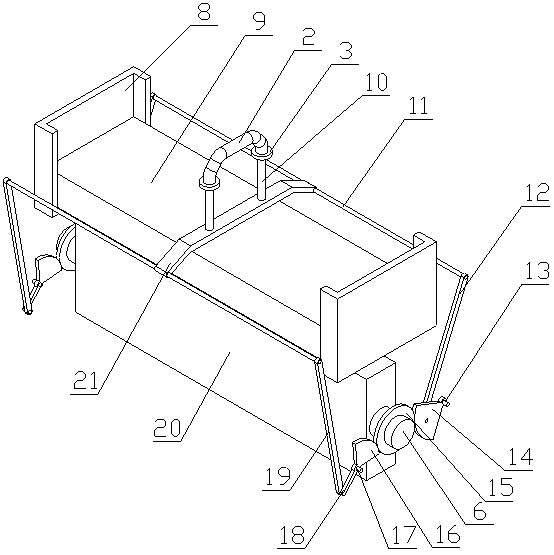

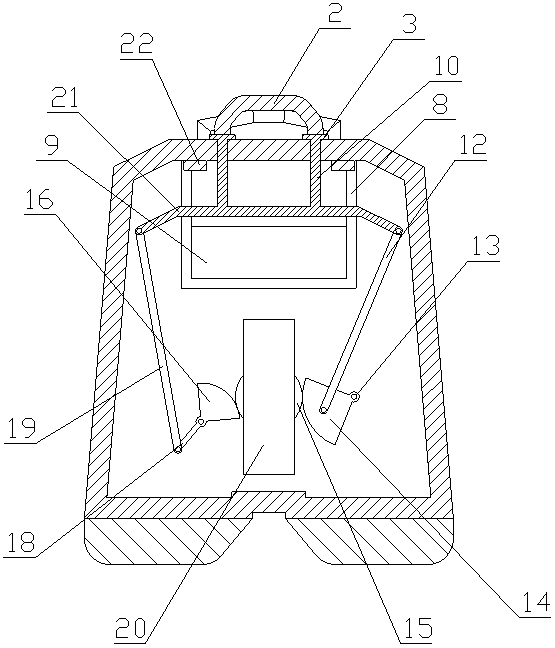

[0021] An automatic permanent magnet jack of the present invention is realized as follows: an automatic permanent magnet jack of the present invention is composed of a main device and a magnetic adsorption device, and the main device is composed of a jack shell (1), a lifting ring (4) ), a bottom suction cup (7) and an elastic block (22). The bottom suction cup (7) is placed at the bottom of the jack shell (1), and the two lifting rings (4) are symmetrically placed on the jack shell (1). ), an elastic block (22) is placed on the inner surface of the top end of the jack housing (1), the elastic block (22) corresponds to the lifting frame (21), and the elastic block (22) It is a rubber block, preferably two elastic blocks (22), and the magnetic adsorption device consists of a sliding ring (2), a limit ring (3), a bearing (5), a rotating shaft (6), a fixed seat (8), Fixed magnet (9), slide bar (10), cross bar (11), No. 1 connecting rod (12), No. 1 fixed column (13), No. 1 sector ...

Embodiment 2

[0024] The difference between this embodiment and Embodiment 1 is that a spring (23) is added on the sliding rod (10), and the spring (23) is located between the top of the jack housing (1) and the lifting frame (21); using When it is convenient for the permanent magnet jack to put down the object, the inner lifting frame (21) of the jack is reset downward under the action of the spring (23) so that the rotating shaft (6) of the moving magnet (20) is rotated and reset to close the suction magnetic field;

[0025] Example 2:

[0026] The difference between this embodiment and Embodiment 1 is that the No. 1 gear and the No. 2 gear are replaced by the No. 4 gear (26) as a whole, and the No. 1 connecting rod (12) and the No. 2 connecting rod (19) are replaced as a whole with Straight toothed racks (24), one end of the two straight toothed racks (24) is hinged with two ends of the cross bar (11) respectively, and the other end of the straight toothed racks (24) extends vertically d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com