Printing and dyeing equipment combining padder and long-loop steamer

A long-ring steamer, printing and dyeing equipment technology, applied in the direction of processing textile material equipment configuration, textile processing machine accessories, textiles and papermaking, etc. To achieve the effect of reducing steam diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

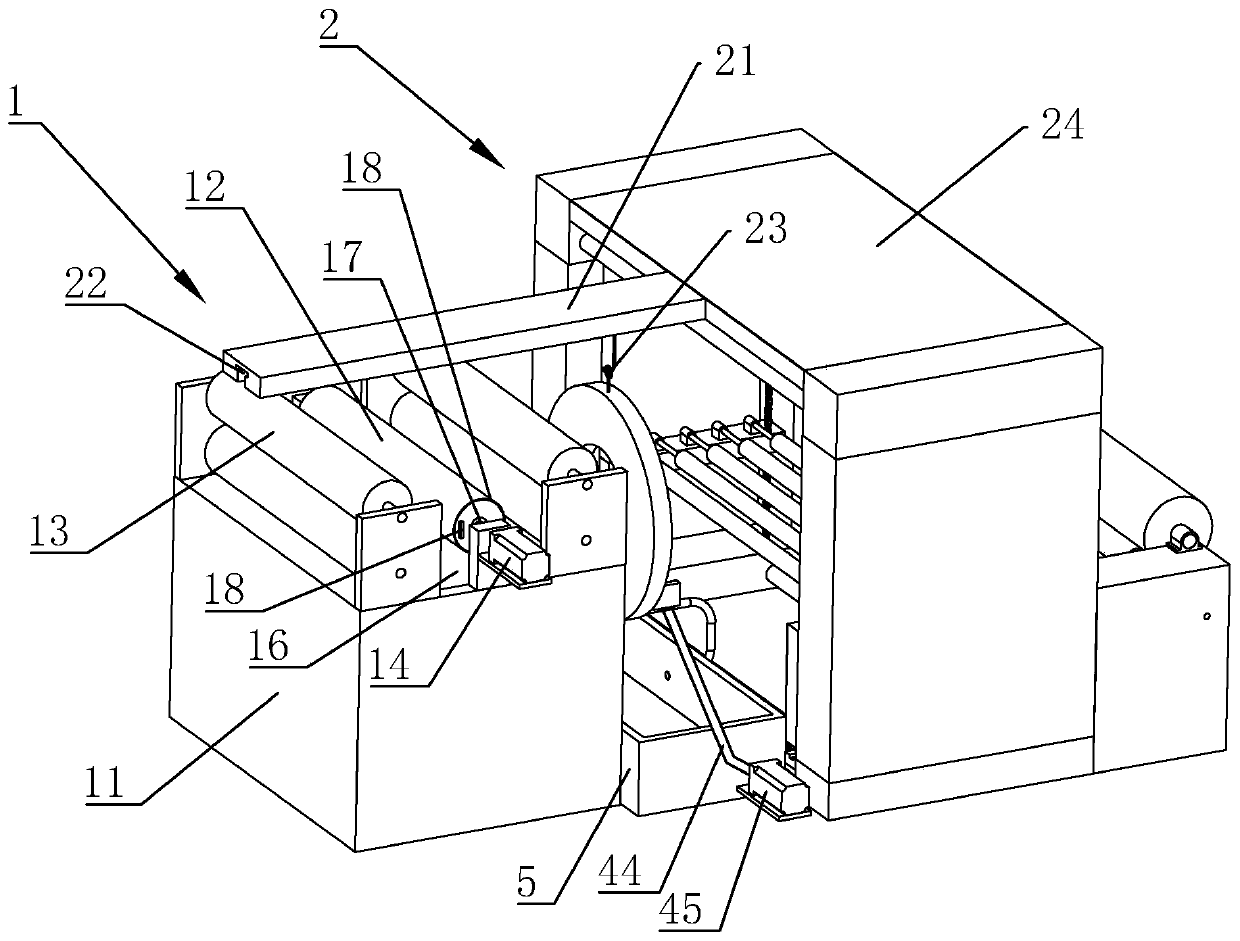

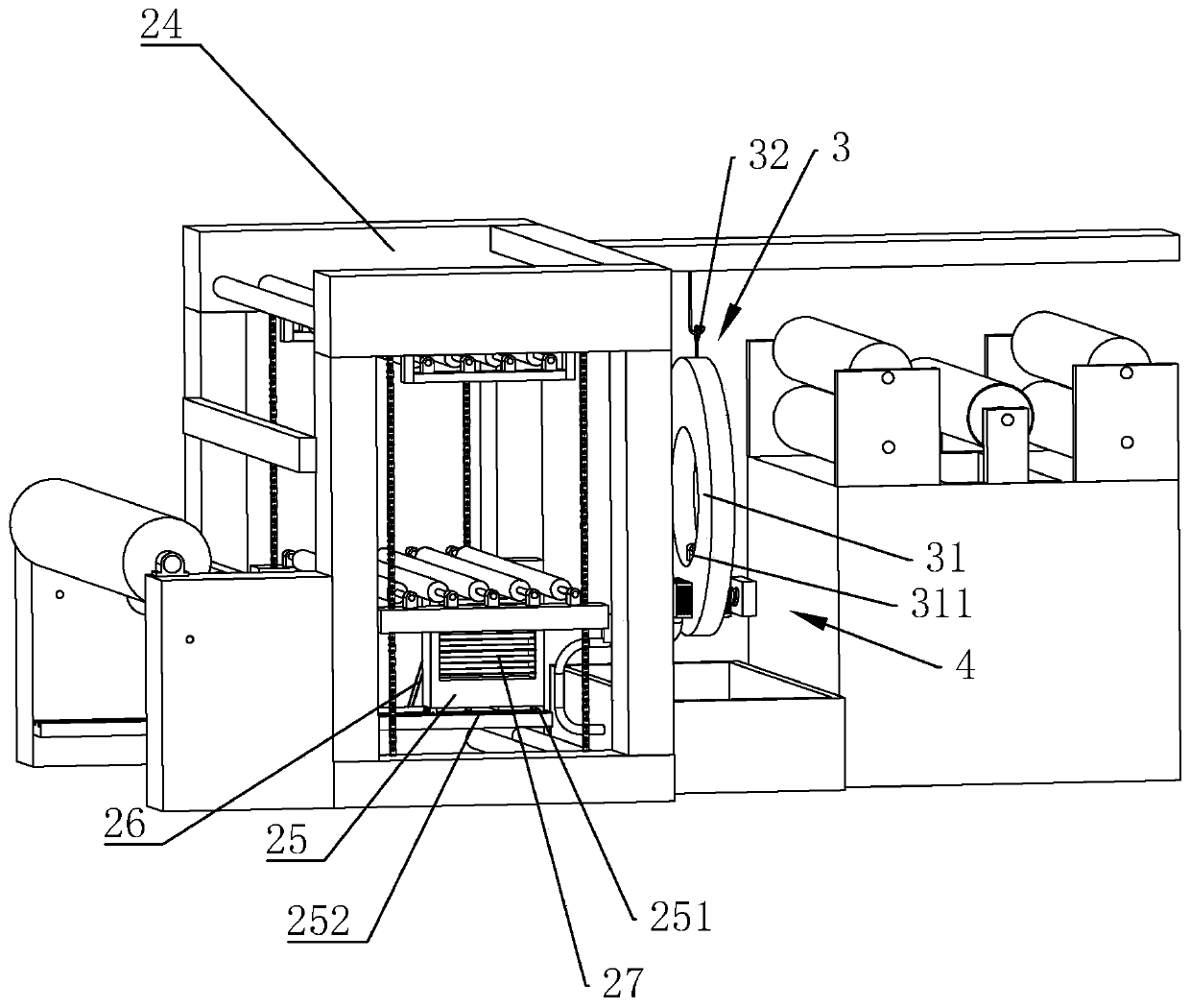

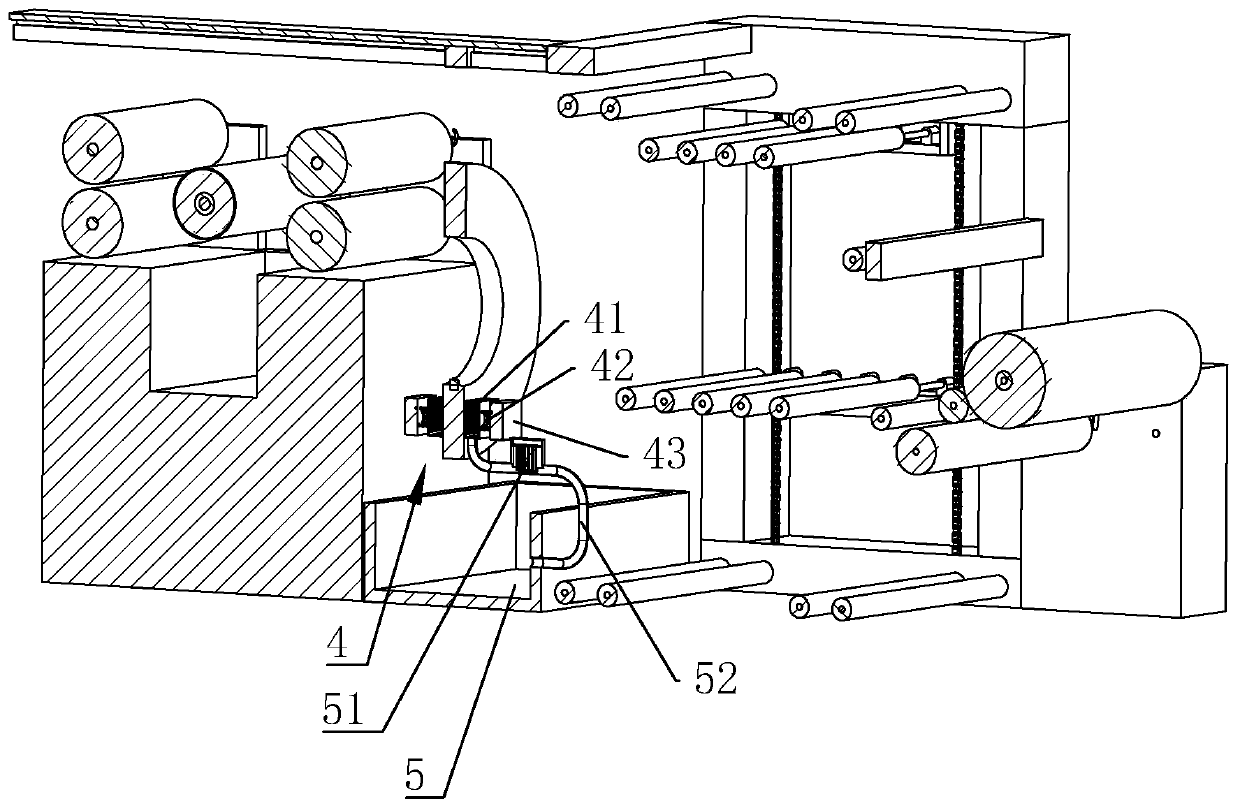

[0033] refer to figure 1 , is a combined printing and dyeing equipment of a pad car and a long-ring steamer disclosed in the present invention, comprising a pad car device 1, and the pad car device 1 includes a vehicle frame 11, and a plurality of guide rollers that can guide the cloth are arranged on the vehicle frame 11 for rolling 13, and the frame 11 is also roll-connected with a cloth feeding cylinder 12 for forwardly conveying the cloth, and the cloth feeding cylinder 12 is coaxially connected with the output shaft of the cloth feeding stepping motor 14. In order to increase the friction between the cloth and the cloth feeding sleeve and improve the hardness of the cloth feeding sleeve, the cloth feeding sleeve 12 is provided with a graphene limit sleeve 15 . The frame 11 is provided with a dye tank 16 for dyeing cloth, and the cloth feed cylinder 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com