Method for expanded production and culture of flavor-producing yeast by adopting raw materials

An aroma-producing yeast and expanded culture technology, applied in fungi and other directions, to save costs, avoid moisture, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

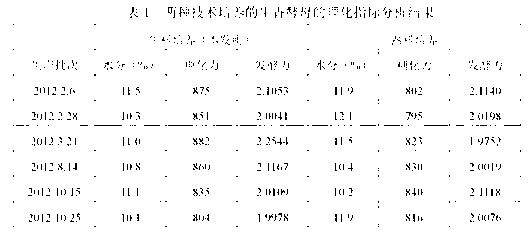

Image

Examples

Embodiment 1

[0033] The present invention adopts the raw material to carry out the method for expanding production and cultivating aroma producing yeast. Firstly, according to the conventional method, the inclined test tube culture, the triangle flask expansion culture and the Karl Fischer tank culture are carried out successively, and finally the solid culture is carried out. The detailed steps of the solid culture are as follows:

[0034] A, the batching of solid culture: expressed in weight percentage, described solid culture batching is made up of bran 75%, rice husk 15% and cornmeal 10%;

[0035] b. Weigh various raw materials according to the composition of the solid culture ingredients in step a, put the various raw materials in a steaming ball and mix them evenly, then add phosphoric acid with a mass percentage concentration of 2%, and adjust its pH value to 4.5; then add Cultivate liquid strains in Karst jars accounting for 52% of the total weight of solid culture ingredients, and ...

Embodiment 2

[0036] Embodiment 2: basically the same as Embodiment 1, the difference is:

[0037] In step a: the solid culture ingredients are composed of 80% bran, 10% rice husk and 10% cornmeal;

[0038] In step b: then adding Karl Fischer tank culture liquid strains accounting for 50% of the total weight of the solid culture ingredients.

Embodiment 3

[0039] Embodiment 3: basically the same as Embodiment 1, the difference is:

[0040] In step a: the solid culture ingredients are composed of 70% bran, 10% rice husk and 20% cornmeal;

[0041] In step b: then add Karl Fischer tank culture liquid strains accounting for 55% of the total weight of the solid culture ingredients.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com