Water pump assembly and dishwasher with same

A component and water pump technology, which is applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, pump components, etc., which can solve the problem of large channel reduction resistance, low hydraulic efficiency, and low heating efficiency of electric pumps, etc. Problems, to achieve the effect of improving hydraulic efficiency, improving water delivery efficiency, and improving dishwashing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

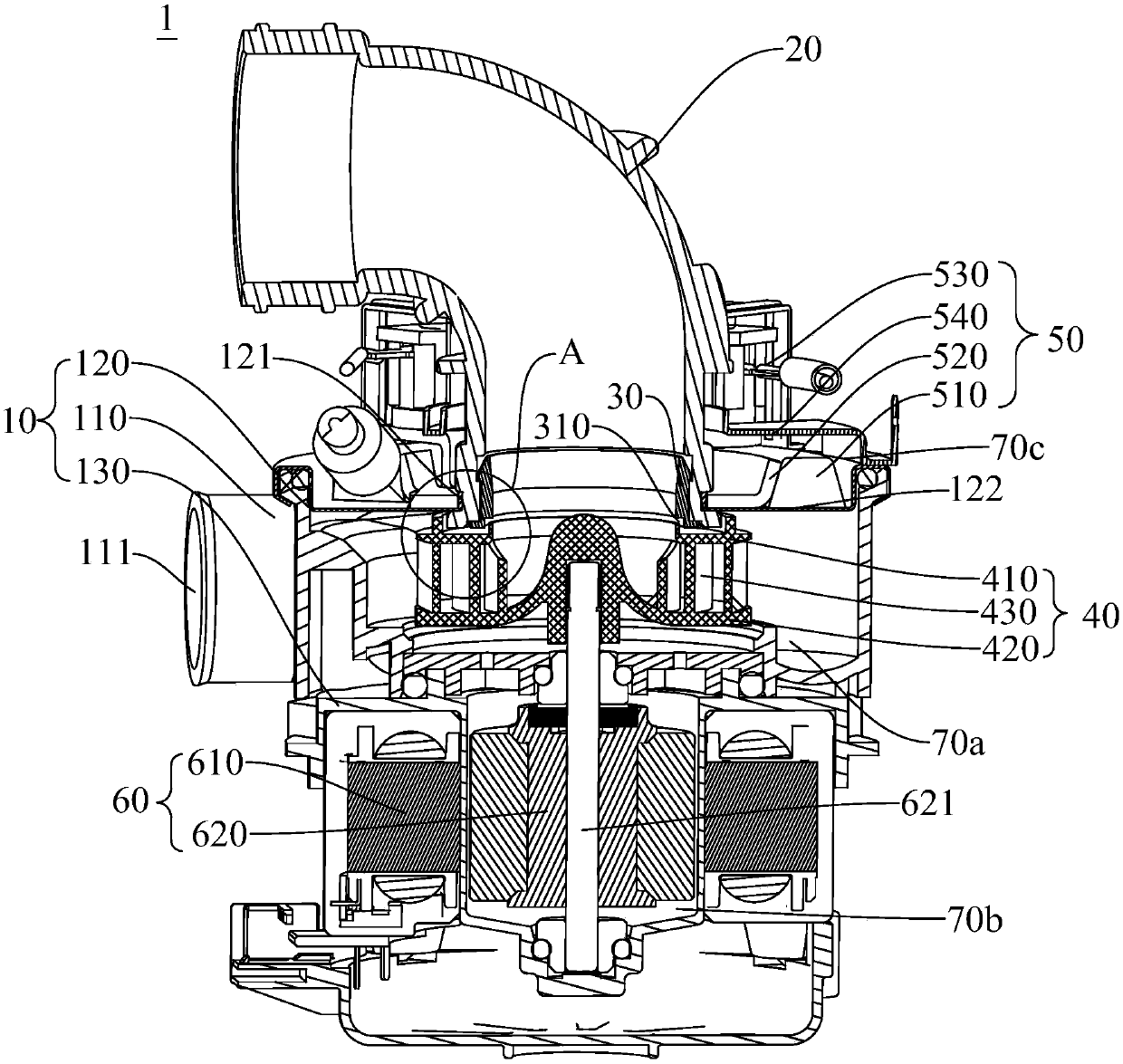

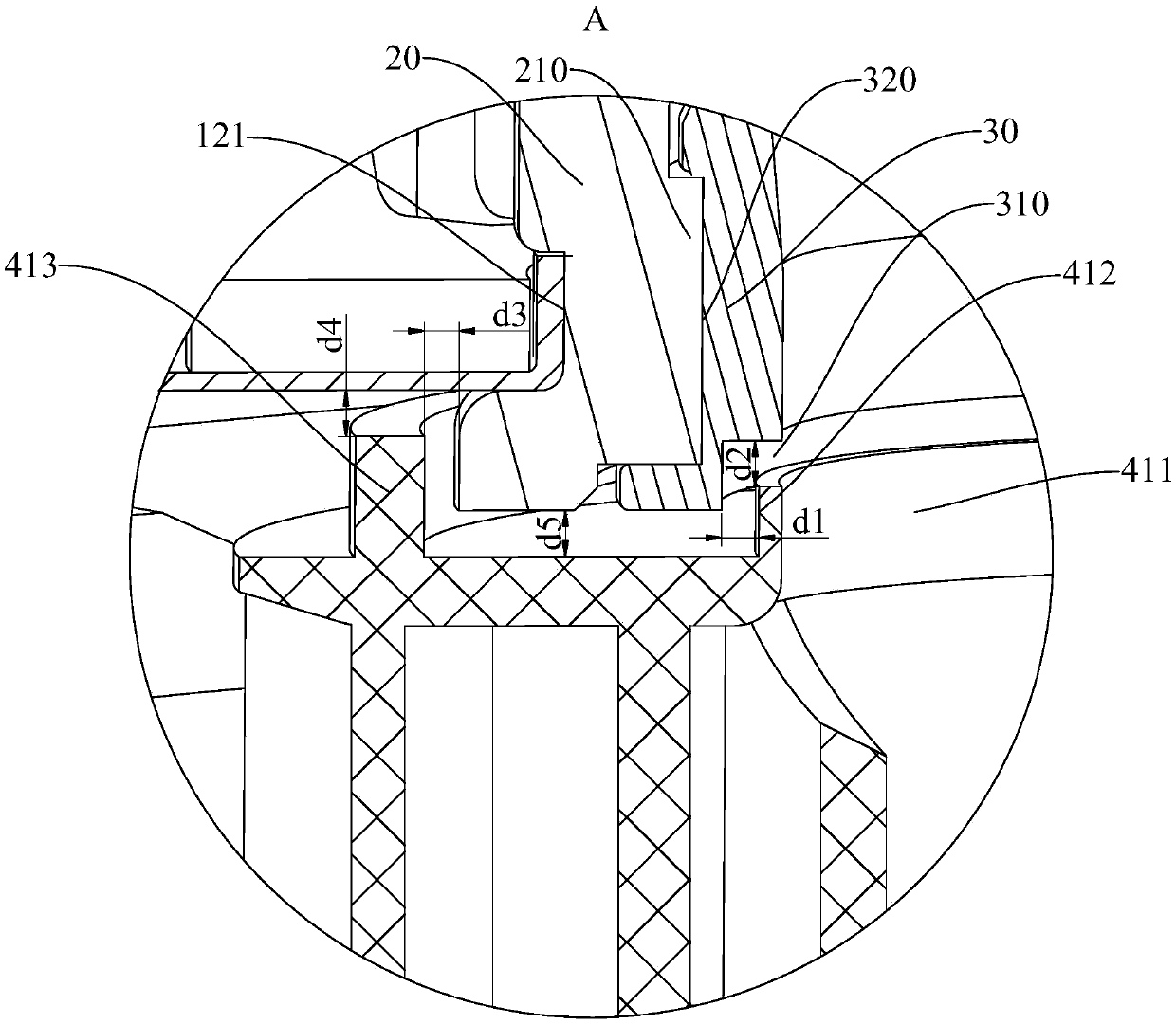

[0052] Such as Figure 1-Figure 2 As shown, the water pump assembly 1 of this embodiment includes a housing 10 , a water inlet pipe 20 , a ferrule 30 , an impeller 40 , a heating assembly 50 and a motor 60 .

[0053] The casing 10 includes a pump casing 110 , a pump cover 120 and a plastic cover plate 130 . The pump casing 110 is open upwards, and a water outlet 111 is provided on a peripheral wall of the pump casing 110 . The pump cover 120 is closed on the pump casing 110 to define the accommodating cavity 70a. A water inlet 121 is formed on the pump cover 120. The water surface 122 of the pump cover 120 is a smooth surface. The plastic cover plate 130 is open upward, and the pump casing 110 is covered on the plastic cover plate 130 to define a motor cavity 70b, and the motor 60 is disposed in the motor cavity 70b.

[0054] The motor 60 includes a stator 610 and a rotor 620. The stator 610 is connected to the plastic cover 130. The rotor 620 is rotatably sleeved inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com