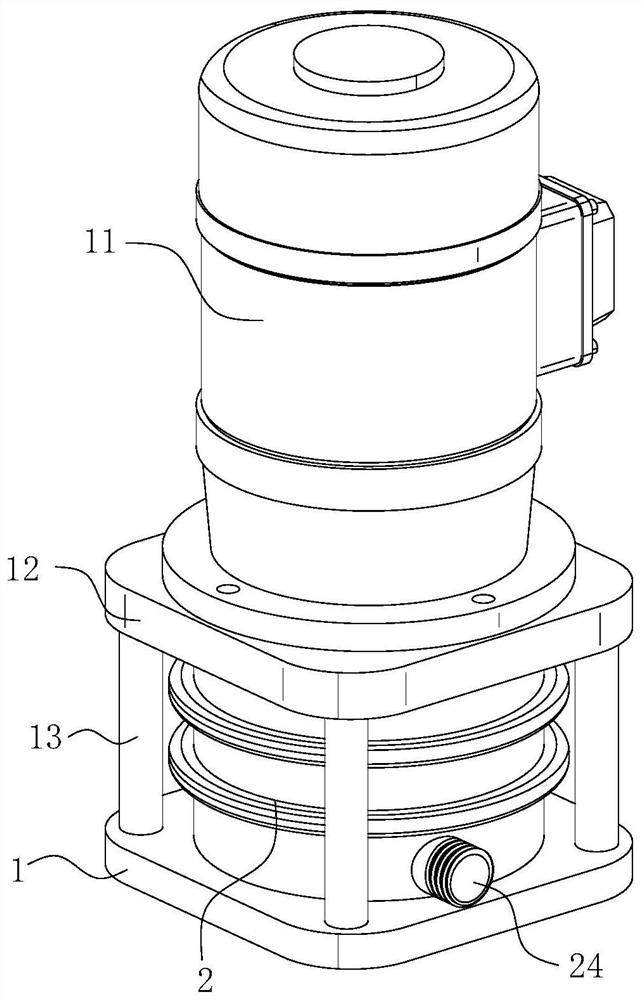

Low-water-suction water pump

A low water absorption, water pump technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of unstable pumping state and pump body damage, and achieve enhanced water delivery efficiency, accelerated flow efficiency, and avoided water flow interruption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

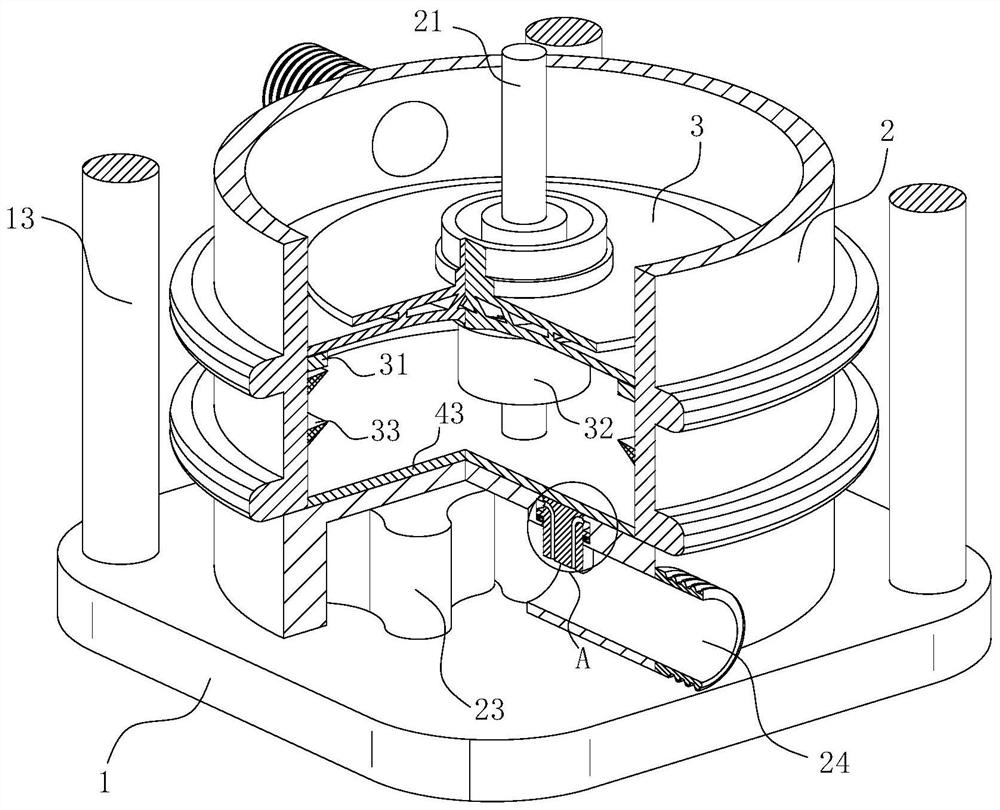

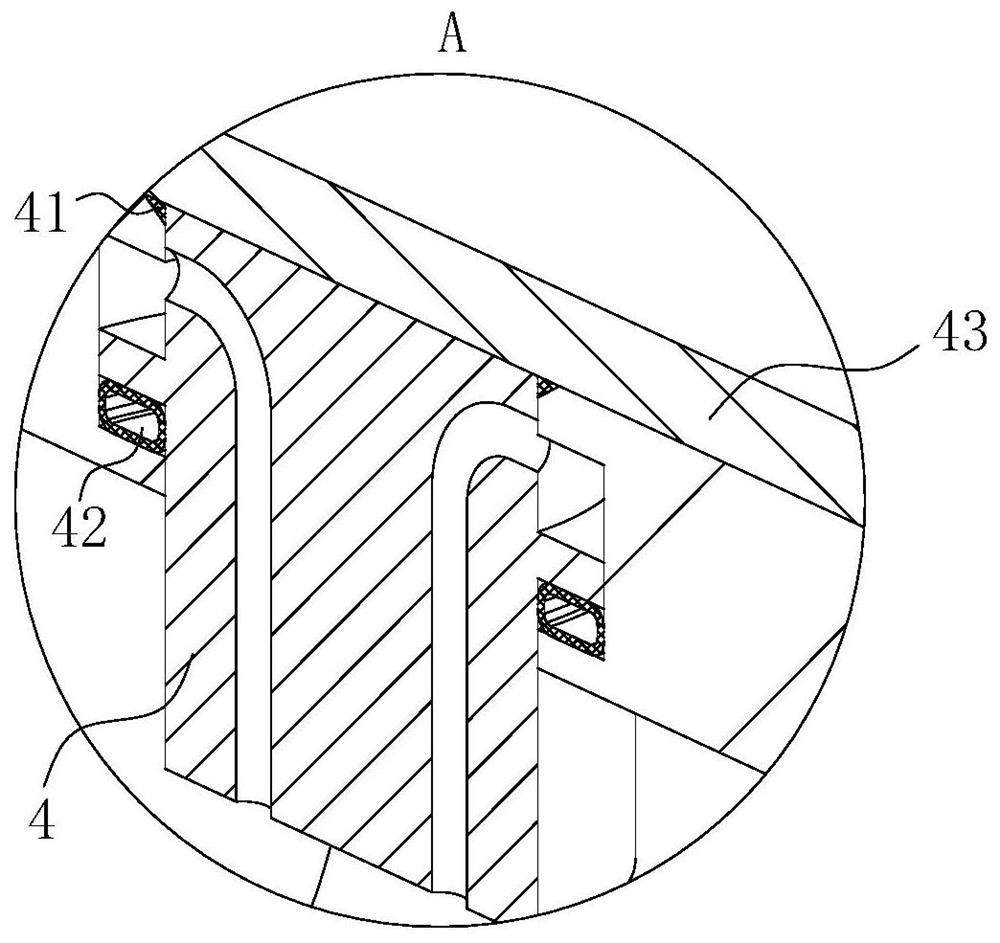

[0025] As an embodiment of the present invention, a sliding groove is provided on the side of the water inlet tank close to the booster chamber; the sliding groove is designed in a "ten" shape; a buoy 4 is slidably connected in the sliding groove; the buoy 4 runs through The sliding groove extends into the water inlet tank; the buoy 4 is provided with a first through hole; the first through hole is designed in an inverted "L" shape; the buoy 4 is made of light water buoyant material; the buoy 4 A sealing ring 41 is fixedly connected to the side wall of the end far away from the water inlet tank; in the initial state, the buoy 4 seals the sliding groove under the action of gravity; during operation, the buoy 4 seals the sliding groove in the initial state, and as the water flow continues to be drawn, the water flow finally Entering the water inlet tank, as the water flows into the booster chamber, it rotates rapidly under the action of the booster wheel 3, thereby increasing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com