Pneumatic shift solenoid valve integrated characteristic test device and test method

A comprehensive characteristic, pneumatic shifting technology, applied in the direction of mechanical valve testing, etc., can solve the problems of single test function, affected by external conditions, easy to fail, etc., to improve accuracy and efficiency, simple design and layout, improve test The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

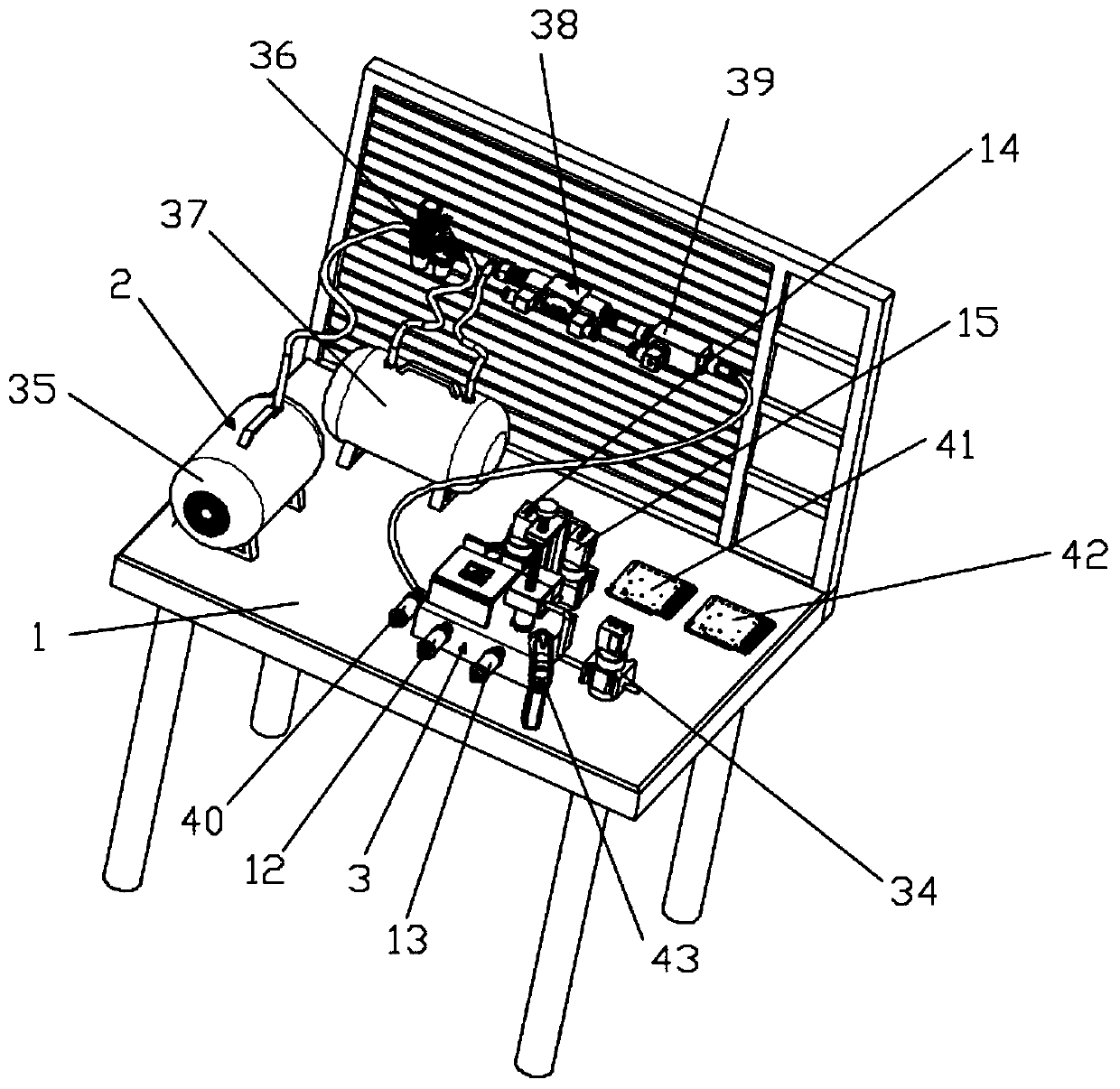

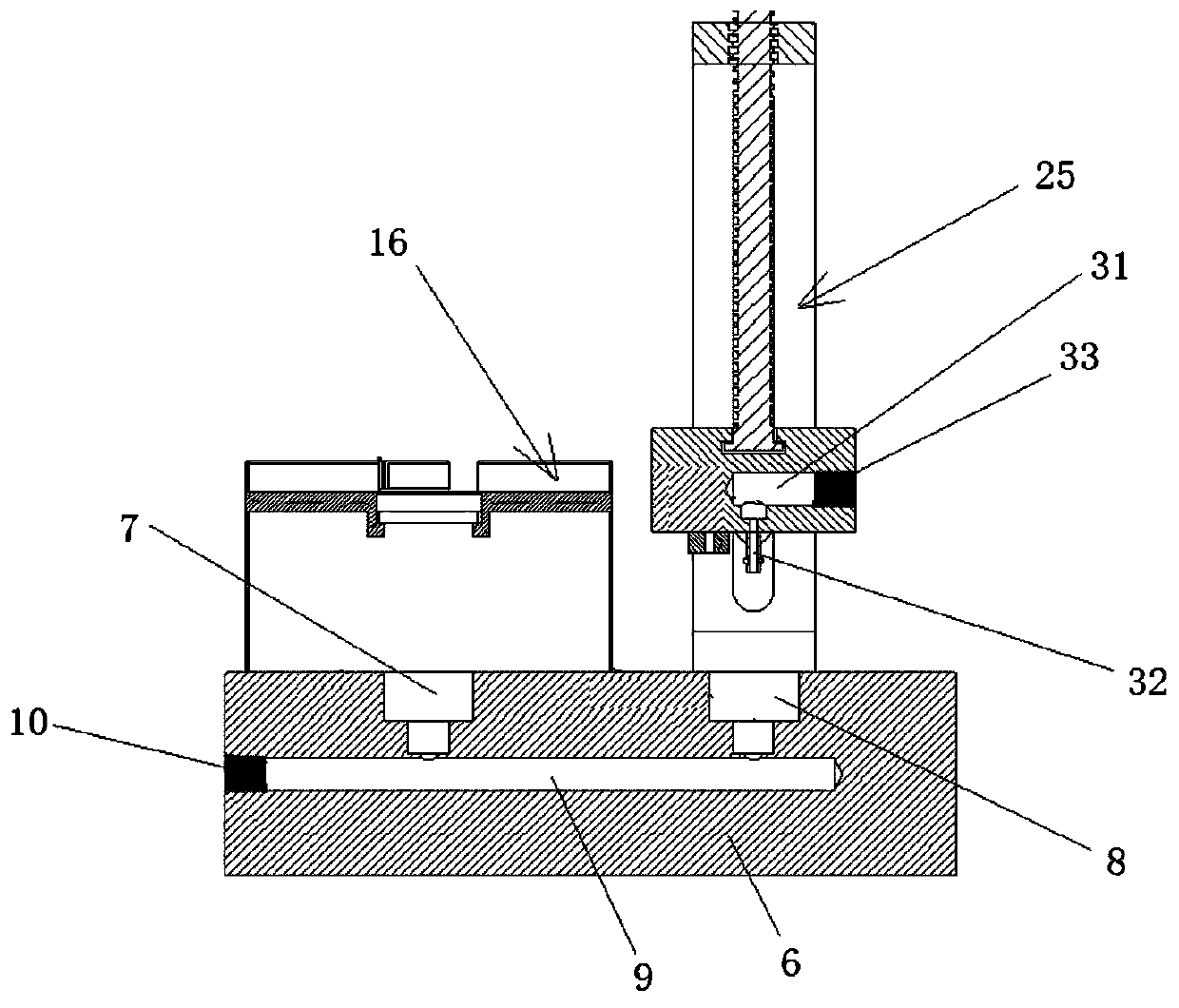

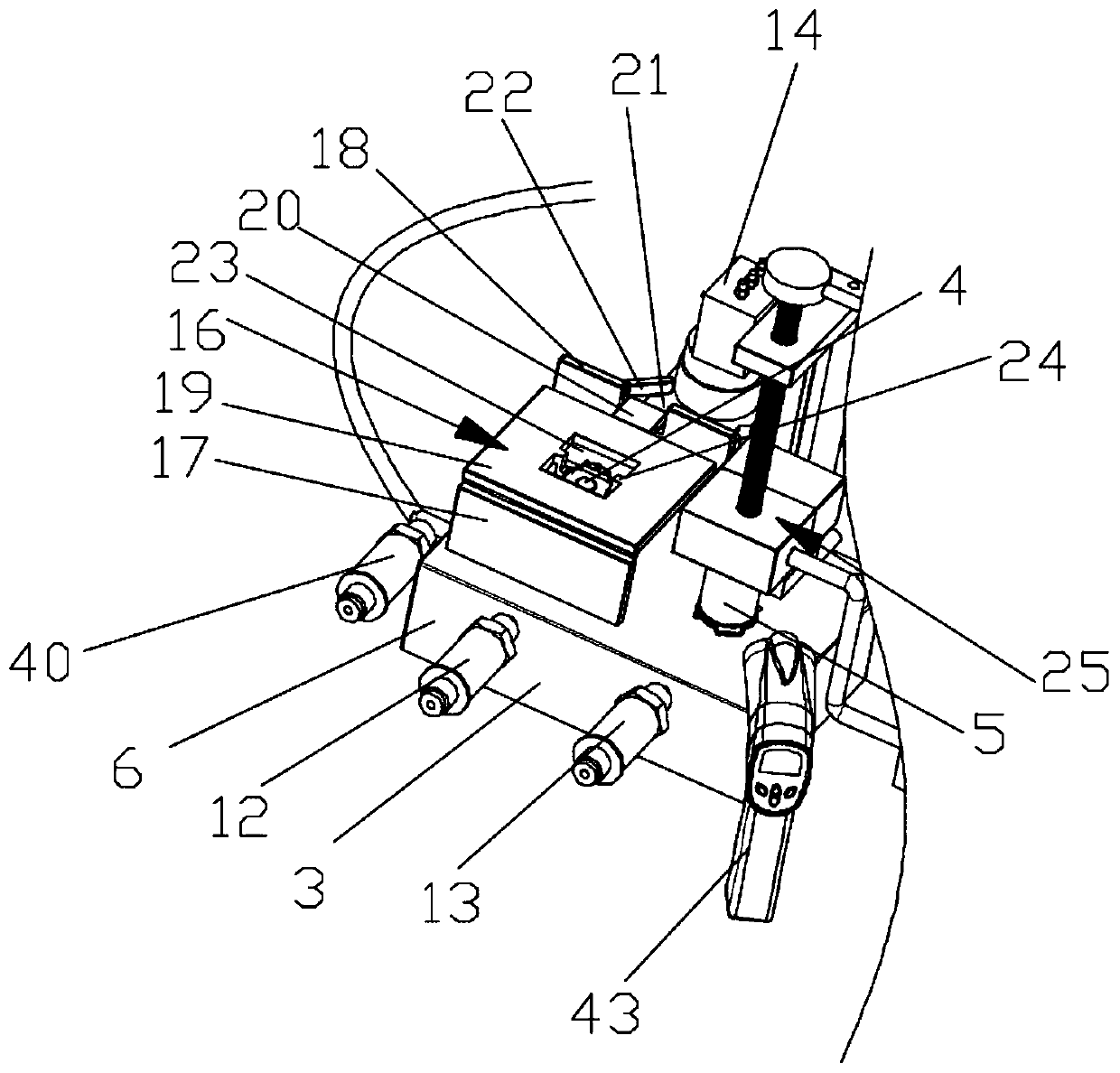

[0028] Embodiment: a kind of comprehensive characteristic test device of pneumatic shift solenoid valve, such as Figure 1-6As shown, it includes a test bench 1, which is provided with an air supply mechanism 2; the test bench 1 is also provided with a fixture 3, and the first test valve 4 and the second tested valve are fixed on the fixture 3. Measured valve 5; the clamp 3 includes a base 6 fixed on the test bench 1, the base 6 is provided with a first positioning step hole 7 for the valve seat of the first tested valve 4 to be inserted, and the base 6 is provided with a first positioning step hole 7 for the first valve seat to be tested. The second positioning step hole 8 where the valve seat of the valve 5 under test is inserted; the base 6 is provided with a first internal air circuit 9, and the first positioning step hole 7 and the second positioning step hole 8 are all connected to the first positioning step hole 8. The internal air passage 9 communicates; the base 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com