Microperation device and method based on capillary force

A capillary force and micro-manipulation technology, applied in the manufacture of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of light damage, electrostatic damage, micro-device damage, etc. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

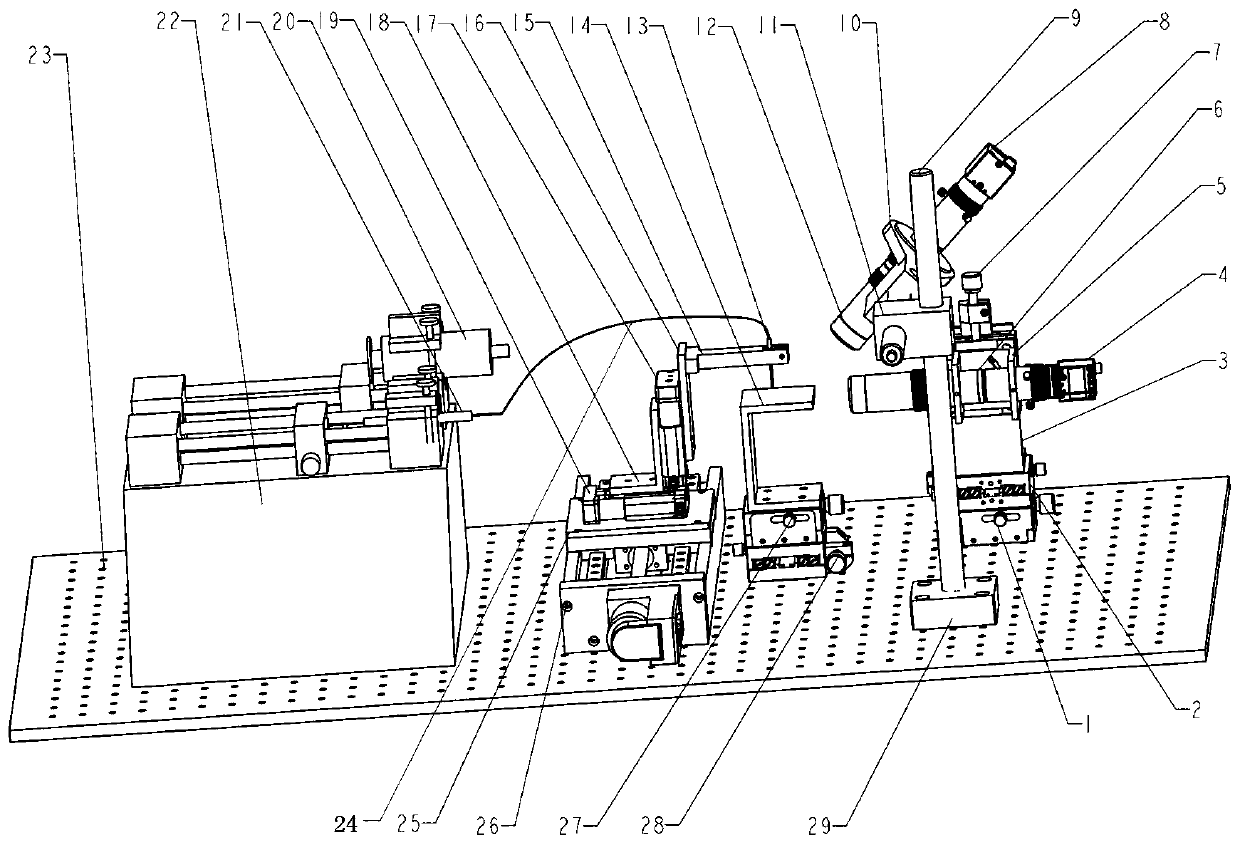

[0046] see figure 1 , a Y-axis electric displacement stage 26 is fixed on the vibration-damping table 23, and a first connecting plate 25 is fixed on the load block of the Y-axis electric displacement stage 26, and the first connecting plate 25 is fixed with an X-axis electric displacement by a hexagon socket bolt. Table 19, the first L-shaped connecting plate 18 is fixed on the loading block of the X-axis electric displacement stage 19 through the inner hexagonal bolt, and the first L-shaped connecting plate 18 is fixed with the Z-axis electric displacement stage 17 through the inner hexagonal bolt, and the Z-axis The loading block of the electric displacement stage 17 is fixed with a second connecting plate 16 by bolts, and the second connecting plate 16 is fixed with an injection needle holder 15 through an inner hexagonal bolt, and the needle holder 15 is provided with an injection needle 13. Multiple needles can be set;

[0047] The loading block of the X-axis electric t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com