Floor brush and assembling method thereof

A technology for assembling columns and assembling parts, which is applied in the direction of the suction nozzle, etc., can solve the problems such as the weak connection between the side plate and the floor brush shell, and the cumbersome way to pick and place the roller brush, so as to achieve simple and convenient pick and place, simple and convenient operation steps, The effect of reducing the overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

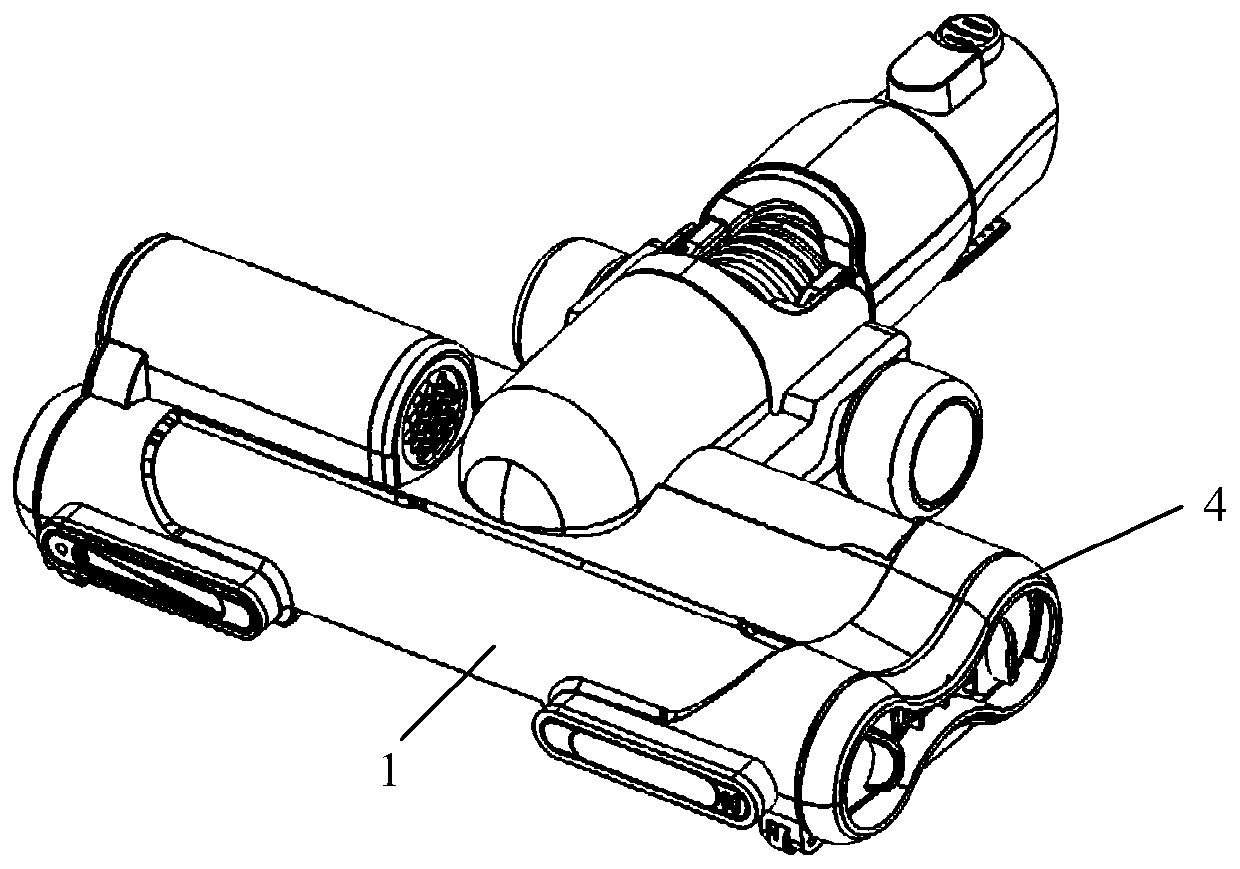

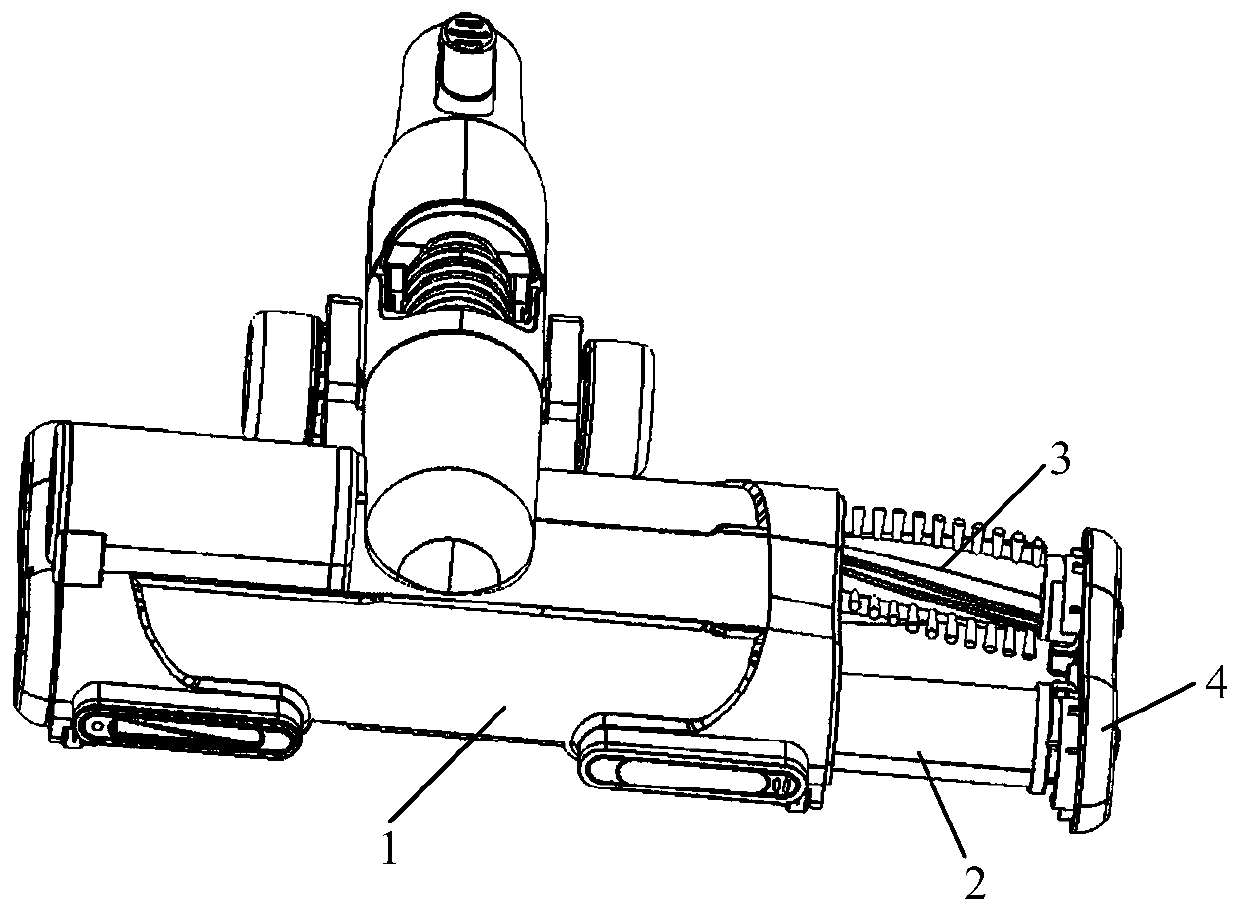

[0059] This embodiment provides a ground brush, see Figure 1-Figure 11 As shown, it includes a main housing 1, a rolling brush assembly (for example, a front rolling brush assembly 2 or / and a rear rolling brush assembly 3), a side cover assembly 4, and a rolling brush transmission assembly for driving the rolling brush assembly to rotate. Components and the roller brush transmission assembly are located in the main housing 1, one end of the roller brush assembly is connected to the roller brush transmission assembly, the other end of the roller brush assembly is detachably connected to the side cover assembly 4, and the roller brush assembly is relatively to the side cover assembly 4 Can be rotated, and the side cover assembly 4 is buckled on one end of the main casing 1 .

[0060]Compared with the prior art, in the floor brush provided by this embodiment, the side cover assembly 4 is detachably connected to the main housing 1 by buckling. When the floor brush collides with w...

Embodiment 2

[0093] This embodiment provides a ground brush assembly method for the ground brush provided in Embodiment 1, including the following steps:

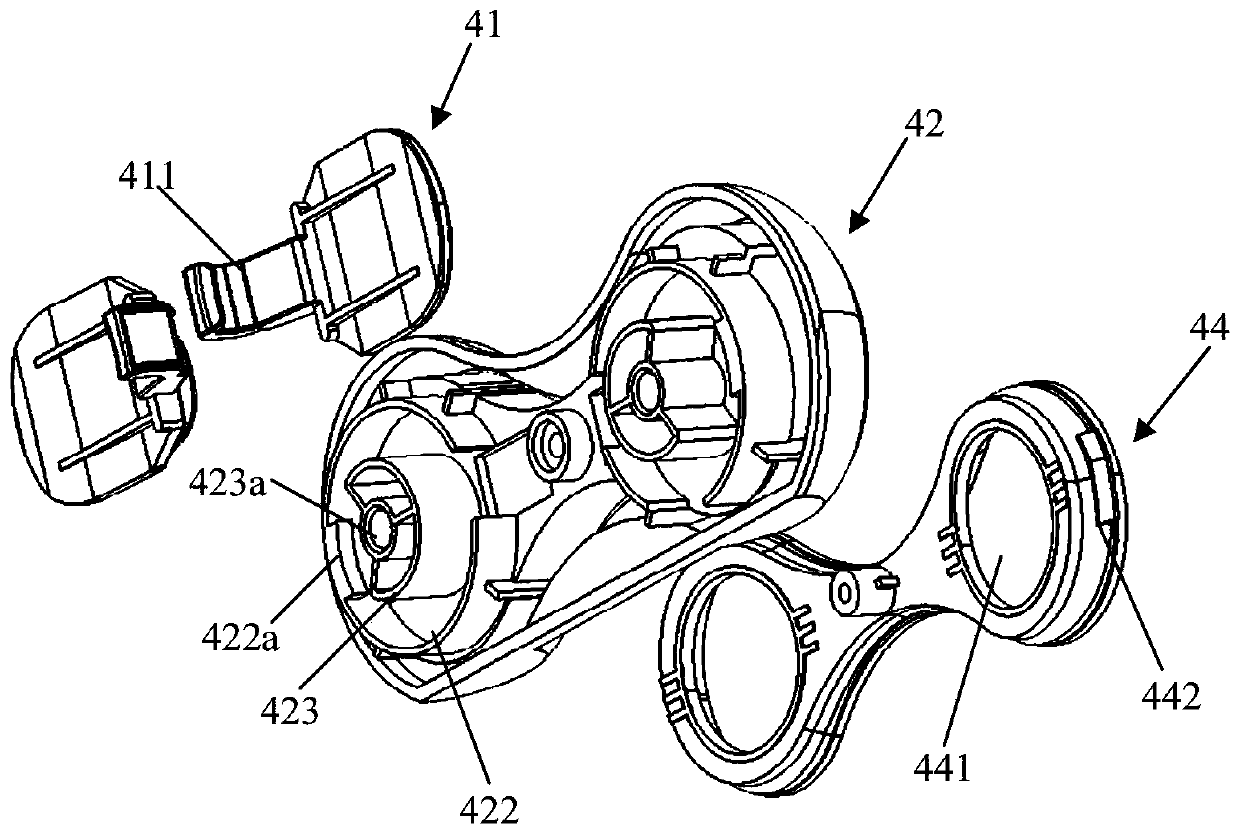

[0094] Step 1: Assemble one end of the roller brush assembly to the inner side of the side cover assembly 4;

[0095] Specifically, the first step is to bring the roller brush assembly close to the second assembly part 422, rotate the roller brush end cover 5 so that the notch 51 corresponds to the convex plate 422a, and place the roller brush end cover 5 in the second assembly part 422 at the same time , the rotating shaft of the roller brush is inserted into the assembly hole 423a, and then the roller brush end cover 5 is rotated clockwise or counterclockwise, so that the notch 51 is misaligned with the convex plate 422a, and one end of the roller brush assembly is assembled to the inner side of the side cover assembly;

[0096] Step 2: Insert the other end of the roller brush assembly into the main housing 1;

[0097] Step 3: Move t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap