A kind of composite oxide and its preparation and application as carbon particle combustion catalyst

A technology of composite oxides and co-solvents, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve the problem of poor catalytic activity and low catalyst cost problem, achieve the effect of low cost, low catalytic temperature and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

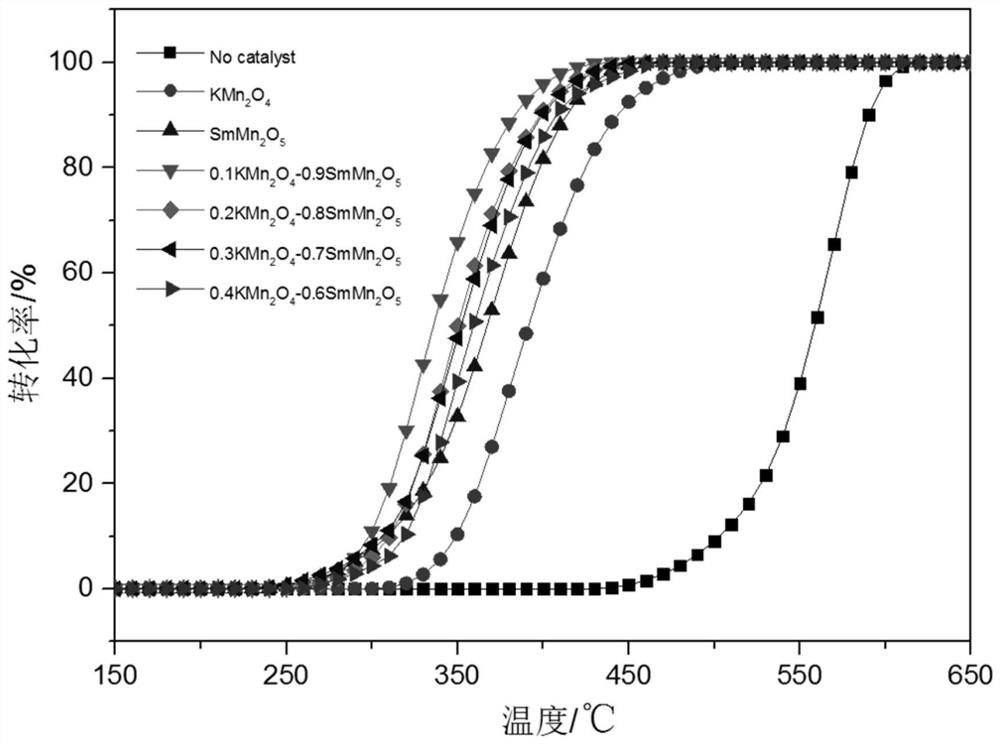

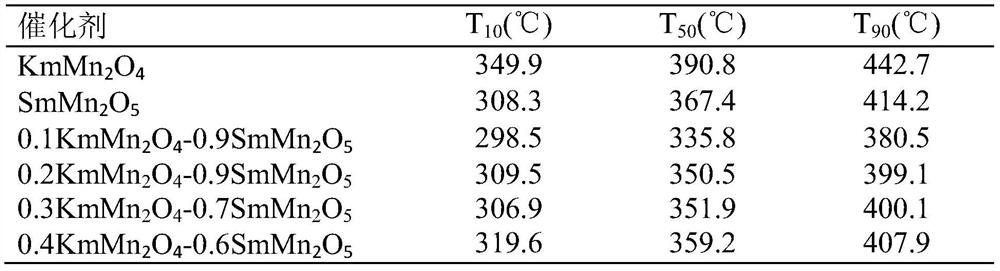

[0031] The preparation formula is 0.1KMn 2 o 4 -0.9SmMn 2 o 5 Spinel-modified mullite-type composite oxide catalysts for carbon particle combustion. Weigh samarium nitrate [Sm(NO 3 ) 3 ·6H 2 O] 2.0007g (0.0045mol), manganese nitrate [Mn(NO 3 ) 3 4H 2 O] 2.5100g (0.01mol), potassium nitrate (KNO 3 ) 0.05055g (0.005mol), was added to the mixture of 6.5ml ethylene glycol and 3.5ml methanol, followed by citric acid [C 6 h 8 o 7 ·H 2 O] 3.4673g (0.015mol) and stirred for 4h to fully dissolve to obtain a catalyst precursor. Then, the temperature was raised to 400°C at a heating rate of 1°C / min and kept for 4 hours, and continued to be heated at the same heating rate to 700°C, kept for 4 hours, and then naturally cooled to room temperature to obtain a tan powder sample.

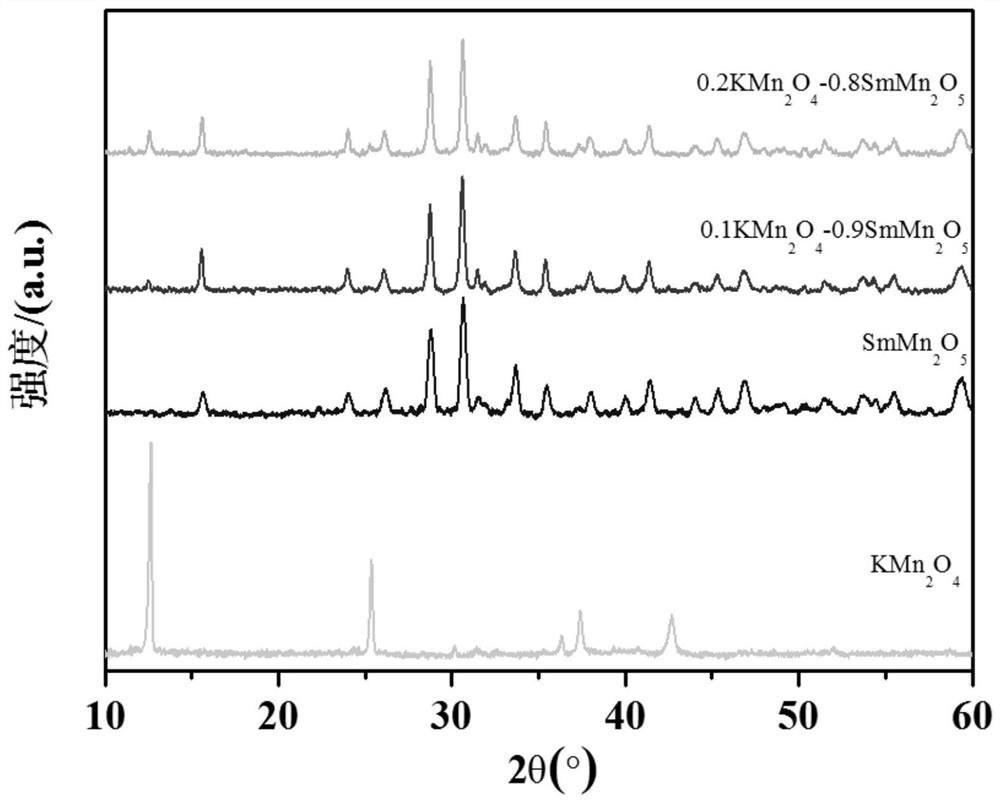

[0032] Through the analysis and identification of powder X-ray diffraction pattern, the results are as follows: figure 2 From the second line, it can be seen that the powder is mainly spinel-modified...

Embodiment 2

[0034] The preparation formula is 0.2KMn 2 o 4 -0.8SmMn 2 o 5 Spinel-modified mullite-type composite oxide catalysts for carbon particle combustion. Weigh samarium nitrate [Sm(NO 3 ) 3 ·6H 2 O] 1.7784g (0.004mol), manganese nitrate [Mn(NO 3 ) 3 4H 2 O] 2.5100g (0.01mol), potassium nitrate (KNO 3 ) 0.1011g (0.001mol), was added to the mixture of 6.5ml ethylene glycol and 3.5ml methanol, followed by citric acid [C 6 h 8 o 7 ·H 2 O] 3.4673g (0.015mol) and stirred for 4h to fully dissolve to obtain a catalyst precursor. Then, the temperature was raised to 400°C at a heating rate of 1°C / min and kept for 4 hours, and continued to be heated at the same heating rate to 700°C, kept for 4 hours, and then naturally cooled to room temperature to obtain a tan powder sample.

[0035] Through the analysis and identification of powder X-ray diffraction pattern, the results are as follows: figure 2 From the first line, it can be seen that the powder is mainly spinel-modified mu...

Embodiment 3

[0037] The preparation formula is 0.3KMn 2 o 4 -0.7SmMn 2 o 5 Spinel-modified mullite-type composite oxide catalysts for carbon particle combustion. Weigh samarium nitrate [Sm(NO 3 ) 3 ·6H 2 O] 1.5561g (0.0035mol), manganese nitrate [Mn(NO 3 ) 3 4H 2 O] 2.5100g (0.01mol), potassium nitrate (KNO 3 ) 0.1517g (0.0015mol), was added to the mixture of 6.5ml ethylene glycol and 3.5ml methanol, followed by citric acid [C 6 h 8 o 7 ·H 2 O] 3.4673g (0.015mol) and stirred for 4h to fully dissolve to obtain a catalyst precursor. Then, the temperature was raised to 400°C at a heating rate of 1°C / min and kept for 4 hours, and continued to be heated at the same heating rate to 700°C, kept for 4 hours, and then naturally cooled to room temperature to obtain a tan powder sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com